CrashDuringApproachtoLanding

EmpireAirlinesFlight8284

AvionsdeTransportRégional

AerospatialeAleniaATR42‐320,N902FX

Lubbock,Texas

January27,2009

Accident Report

NTSB/AAR-11/02

PB2011-910402

National

Transportation

Safety Board

NTSB/AAR-11/02

PB2011-910402

Notation 8093A

Adopted April 26, 2011

Aircraft Accident Report

Crash During Approach to Landing

Empire Airlines Flight 8284

Avions de Transport Régional

Aerospatiale Alenia ATR 42-320, N902FX

Lubbock, Texas

January 27, 2009

National

Transportation

Safety Board

490 L’Enfant Plaza, S.W.

Washington, D.C. 20594

National Transportation Safety Board. 2011. Crash During Approach to Landing, Empire Airlines

Flight 8284, Avions de Transport Régional Aerospatiale Alenia ATR 42-320, N902FX, Lubbock,

Texas, January 27, 2009. Aircraft Accident Report NTSB/AAR-11/02. Washington, DC.

Abstract: This accident report discusses the January 27, 2009, accident involving Empire Airlines

flight 8284, an Avions de Transport Régional Aerospatiale Alenia ATR 42-320, N902FX, which crashed

short of the runway at Lubbock Preston Smith International Airport, Lubbock, Texas. The captain

sustained serious injuries, and the first officer sustained minor injuries. The airplane was substantially

damaged. The airplane was registered to FedEx Corporation and operated by Empire Airlines, Inc., as a

14 Code of Federal Regulations Part 121 supplemental cargo flight. Instrument meteorological conditions

prevailed, and an instrument flight rules flight plan was filed. The safety issues discussed in this report

include the flight crew’s actions in response to the flap anomaly, the continuation of the unstabilized

approach, the dispatch of the flight into freezing drizzle conditions, the efficiency of the emergency

response, and simulator-based training for pilots who fly in icing conditions. Nine safety

recommendations are addressed to the Federal Aviation Administration.

The National Transportation Safety Board is an independent Federal agency dedicated to promoting aviation,

railroad, highway, marine, pipeline, and hazardous materials safety. Established in 1967, the agency is mandated by

Congress through the Independent Safety Board Act of 1974 to investigate transportation accidents, determine the

probable causes of the accidents, issue safety recommendations, study transportation safety issues, and evaluate the

safety effectiveness of government agencies involved in transportation. The Safety Board makes public its actions

and decisions through accident reports, safety studies, special investigation reports, safety recommendations, and

statistical reviews.

Recent publications are available in their entirety on the Internet at <http://www.ntsb.gov>. Other information about

available publications also may be obtained from the website or by contacting:

National Transportation Safety Board

Records Management Division, CIO-40

490 L’Enfant Plaza, SW

Washington, DC 20594

(800) 877-6799 or (202) 314-6551

Safety Board publications may be purchased, by individual copy or by subscription, from the National Technical

Information Service. To purchase this publication, order report number PB2011-910402 from:

National Technical Information Service

5285 Port Royal Road

Springfield, Virginia 22161

(800) 553-6847 or (703) 605-6000

The Independent Safety Board Act, as codified at 49 U.S.C. Section 1154(b), precludes the admission into evidence

or use of Board reports related to an incident or accident in a civil action for damages resulting from a matter

mentioned in the report.

NTSB Aircraft Accident Report

Contents

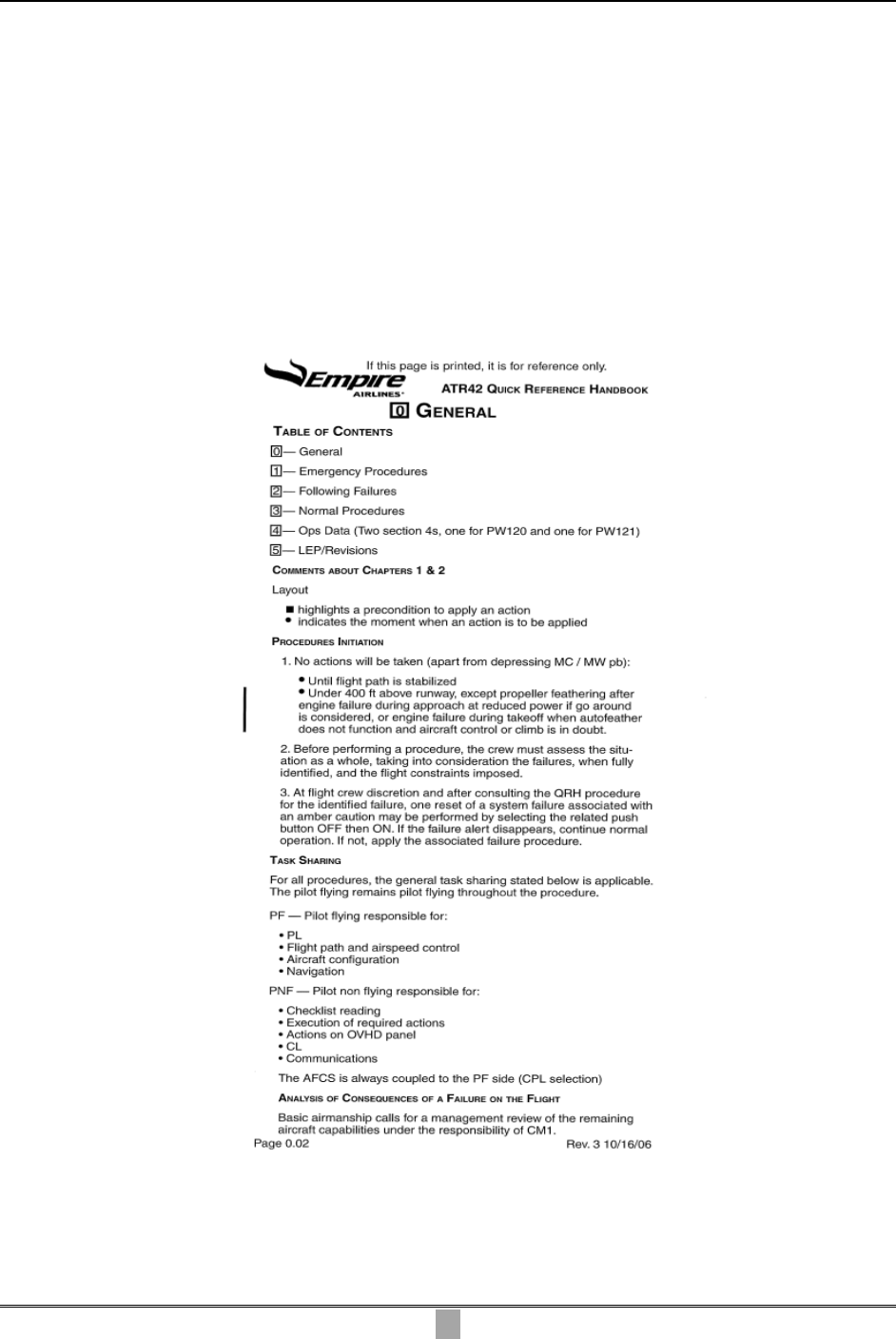

Figures ........................................................................................................................................... iv

Abbreviations and Acronyms .......................................................................................................v

Executive Summary ..................................................................................................................... ix

1. Factual Information ...................................................................................................................1

1.1 History of Flight .........................................................................................................................1

1.2 Injuries to Persons ......................................................................................................................5

1.3 Damage to Airplane ...................................................................................................................5

1.4 Other Damage ............................................................................................................................5

1.5 Personnel Information ................................................................................................................6

1.5.1 The Captain ......................................................................................................................6

1.5.2 The First Officer ..............................................................................................................6

1.5.3 Flight Crew’s Rest Opportunities ....................................................................................7

1.5.3.1 The Captain ....................................................................................................... 7

1.5.3.2 The First Officer ............................................................................................... 8

1.6 Airplane Information .................................................................................................................8

1.6.1 General .............................................................................................................................8

1.6.2 Flap System .....................................................................................................................9

1.6.3 Deicing, Anti-Icing, and Anti-Icing Advisory Systems ................................................11

1.6.4 Flight Instruments ..........................................................................................................11

1.6.4.1 Airspeed Indicator ........................................................................................... 11

1.6.4.2 Electronic Flight Information System ............................................................. 13

1.6.5 Automatic Flight Control System ..................................................................................13

1.6.6 Stall Protection System ..................................................................................................13

1.7 Meteorological Information .....................................................................................................14

1.8 Aids to Navigation ...................................................................................................................14

1.9 Communications ......................................................................................................................15

1.10 Airport Information ................................................................................................................15

1.10.1 Emergency Plan ...........................................................................................................15

1.10.2 Snow and Ice Control Plan ..........................................................................................16

1.11 Flight Recorders .....................................................................................................................16

1.11.1 Cockpit Voice Recorder ..............................................................................................16

1.11.2 Flight Data Recorder ....................................................................................................17

1.12 Wreckage and Impact Information ........................................................................................17

1.13 Medical and Pathological Information ...................................................................................18

1.14 Fire .........................................................................................................................................18

1.15 Survival Aspects ....................................................................................................................18

1.15.1 Flight Crew Egress ......................................................................................................18

1.15.2 Emergency Response ...................................................................................................18

1.16 Tests and Research .................................................................................................................21

1.16.1 Airplane Performance Study and Simulator Evaluations ............................................21

i

NTSB Aircraft Accident Report

1.16.1.1 Effects of Flap Asymmetry ........................................................................... 21

1.16.1.2 Effects of Airframe Ice Accretion ................................................................. 22

1.16.2 Terrain Awareness and Warning System ....................................................................23

1.16.3 Flap System Component Examinations .......................................................................24

1.16.3.1 Hydraulic Fluid Testing ................................................................................ 25

1.16.3.2 Maintenance History ..................................................................................... 25

1.16.3.3 Flap Asymmetry Event Involving Another Airplane .................................... 25

1.16.4 Deicing and Anti-Icing System Examinations ............................................................26

1.16.5 Autopilot Disconnect Alert ..........................................................................................26

1.17 Organizational and Management Information .......................................................................26

1.17.1 Pilot Standard Operating Procedures and Training .....................................................27

1.17.1.1 Flap Anomalies ............................................................................................. 27

1.17.1.2 Stabilized Approach and Go Around ............................................................ 31

1.17.1.3 Terrain Awareness and Warning System ...................................................... 32

1.17.1.4 Airspeed Bugs ............................................................................................... 32

1.17.1.5 Aileron Mistrim with Autopilot Engaged ..................................................... 33

1.17.1.6 Deicing and Anti-Icing Systems ................................................................... 33

1.17.1.7 Crew Resource Management ........................................................................ 34

1.17.1.8 Weather Information and Training ............................................................... 35

1.17.1.9 Stall and Near-Stall Recoveries .................................................................... 36

1.17.2 Aircraft Deicing Program (Ground) ............................................................................36

1.17.3 Flight Dispatch .............................................................................................................36

1.17.4 Hazardous Materials ....................................................................................................38

1.17.5 Federal Aviation Administration Oversight ................................................................38

1.17.6 Previous Accidents ......................................................................................................39

1.18 Additional Information ..........................................................................................................40

1.18.1 Postaccident Safety Action ..........................................................................................40

1.18.1.1 Federal Aviation Administration .................................................................. 40

1.18.1.2 Empire Airlines ............................................................................................. 41

1.18.1.3 FedEx Feeder Operations .............................................................................. 42

1.18.2 Previously Issued Safety Recommendations ...............................................................43

1.18.2.1 Flight Crew Monitoring and Workload Management Skills for Single and

Multiple Abnormal Situations..................................................................................... 43

1.18.2.2 Go-Around Callout ....................................................................................... 45

1.18.2.3 Low-Airspeed Alerting Systems ................................................................... 45

1.18.2.4 First Officer Assertiveness ............................................................................ 46

1.18.3 Airplane Equipment Options .......................................................................................47

1.18.3.1 Aircraft Performance Monitoring System .................................................... 47

1.18.3.2 Flap Malfunction or Asymmetry Light ......................................................... 48

1.18.3.3 Ice Evidence Probe ....................................................................................... 49

2. Analysis .....................................................................................................................................50

2.1 General .....................................................................................................................................50

2.2 Accident Sequence ...................................................................................................................52

2.3 Human Performance ................................................................................................................54

2.3.1 Captain’s Nonstandard Responses .................................................................................55

2.3.2 Flight Crew’s Failure to Monitor Airspeed ...................................................................57

ii

NTSB Aircraft Accident Report

2.3.2.1 Airspeed References ....................................................................................... 58

2.3.2.2 Flight Crew Monitoring Skills and Techniques .............................................. 60

2.3.3 Crew Resource Management .........................................................................................61

2.3.4 Go-Around Callout ........................................................................................................63

2.3.5 Training for Single and Multiple Abnormal Situations Occurring at Low Altitude .....64

2.3.6 Fatigue Considerations ..................................................................................................65

2.3.6.1 Role of Fatigue in Flight Crew Performance .................................................. 67

2.4 Operations Issues .....................................................................................................................69

2.4.1 Dispatch into Freezing Drizzle Conditions ....................................................................69

2.4.1.1 Flight Crewmember and Dispatcher Training Related to Icing Conditions ... 70

2.4.1.2 Proposed Rulemaking for Airplane Certification Requirements for Flight in

Icing Conditions .......................................................................................................... 72

2.4.2 Training Program and Manual Discrepancies ...............................................................72

2.5 Survival Aspects ......................................................................................................................73

2.5.1 Lack of Occupant and Hazardous Materials Information Available

to First Responders .................................................................................................................73

2.5.2 Inoperative Emergency Response and Mutual Aid Gate ...............................................75

2.6 Airplane Equipment Options ...................................................................................................75

2.6.1 Aircraft Performance Monitoring ..................................................................................75

2.6.2 Flap Malfunction or Asymmetry Light ..........................................................................77

2.6.3 Ice Evidence Probe ........................................................................................................77

2.7 Simulator Training for Icing Encounters .................................................................................78

3. Conclusions ...............................................................................................................................80

3.1 Findings....................................................................................................................................80

3.2 Probable Cause.........................................................................................................................83

4. Recommendations ....................................................................................................................84

Board Member Statements .........................................................................................................86

5. Appendixes ...............................................................................................................................93

Appendix A: Investigation and Hearing ........................................................................................93

Appendix B: Cockpit Voice Recorder Transcript ..........................................................................94

iii

NTSB Aircraft Accident Report

Figures

Figure 1. Aerial view of approach end of runway 17R and location of wreckage. ....................... 5

Figure 2. Flap position indicator. Inset shows the likely needle pointer position during the

flap asymmetry.............................................................................................................................. 10

Figure 3. Exterior flap position fairing. ....................................................................................... 10

Figure 4. Airspeed indicator showing needle pointer; selector knob; and internal, yellow,

white, and red bugs. ...................................................................................................................... 12

Figure 5. View of airport showing relative locations of airport access gates and accident site. . 20

Figure 6. Right side of fuselage showing extensive fire damage to right wing and

flap components. ........................................................................................................................... 24

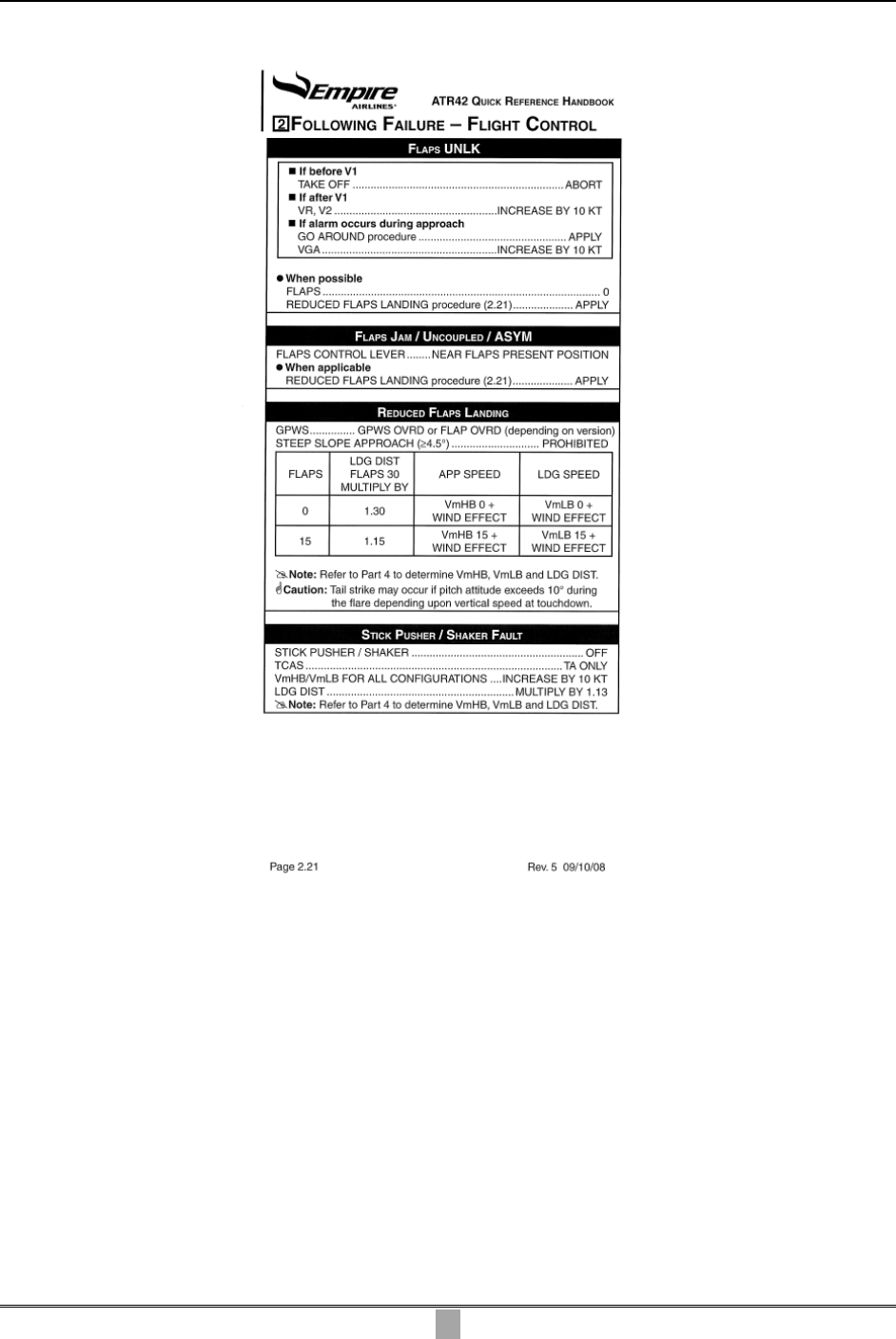

Figure 7. Quick reference handbook page 2.21 with “FLAPS JAM/UNCOUPLED/ASYM” and

“REDUCED FLAPS LANDING” procedures. ............................................................................ 28

Figure 8. General information on page 0.02 of quick reference handbook. ................................ 29

iv

NTSB Aircraft Accident Report

Abbreviations and Acronyms

AAS anti-icing advisory system

AC advisory circular

AD airworthiness directive

ADP aircraft deicing program

ADU advisory display unit

AEP airport emergency plan

AFFF aqueous film forming foam

AFM airplane flight manual

AFW Fort Worth Alliance Airport

agl above ground level

AIM Aeronautical Information Manual

AIRMET airmen’s meteorological information

AOA angle of attack

APM aircraft performance monitoring

ARAC Aviation Rulemaking Advisory Committee

ARFF aircraft rescue and firefighting

ATC air traffic control

ATCT air traffic control tower

ATOS air transportation oversight system

ATR Avions de Transport Régional

ATR 42 Aerospatiale Alenia ATR 42-320

BEA Bureau d’Enquêtes et d’Analyses

CFR Code of Federal Regulations

v

NTSB Aircraft Accident Report

CG center of gravity

CRM crew resource management

CVR cockpit voice recorder

DGAC Direction Générale de l’Aviation Civile

EADI electronic attitude direction indicator

EASA European Aviation Safety Agency

EFS engineering flight simulator

ELP El Paso International Airport

EMS emergency medical service

FAA Federal Aviation Administration

FAF final approach fix

FCOM flight crew operating manual

FDR flight data recorder

FedEx FedEx Corporation

FL flight level

fpm feet per minute

FR Federal Register

FSDO flight standards district office

FSIB flight standards information bulletin

FTM flight training manual

GOM general operations manual

HAZMAT hazardous materials

Hg mercury

IEP ice evidence probe

vi

NTSB Aircraft Accident Report

IFR instrument flight rules

ILS instrument landing system

IMC instrument meteorological conditions

InFO information for operators

KIAS knots indicated airspeed

kts knots

LBB Lubbock Preston Smith International Airport

lbs pounds

LOM locator outer marker

LWD left-wing-down

MAF Midland International Airport

msl mean sea level

NASA National Aeronautics and Space Administration

NPRM notice of proposed rulemaking

NTSB National Transportation Safety Board

NWS National Weather Service

PF pilot flying

PIC pilot-in-command

PM pilot monitoring

PMI principal maintenance inspector

POI principal operations inspector

QRH quick reference handbook

RWD right-wing-down

SAFO safety alert for operators

SIC second-in-command

vii

NTSB Aircraft Accident Report

SIGMET significant meteorological information

SLD supercooled large droplet

SN serial number

SOP standard operating procedure

STC supplemental type certificate

SVFR special visual flight rules

TAWS terrain awareness and warning system

TSB Transportation Safety Board of Canada

VFR visual flight rules

V

ga

minimum approach airspeed for 30° flaps plus 5 kts (not corrected for wind) or

1.1 V

mca

, whichever is greater

V

mca

minimum control airspeed with 5° of bank and the failure of the critical engine

with takeoff flaps and landing gear retracted

V

mHB

30 minimum approach airspeed and target touchdown airspeed with 30° flaps

V

mLB

0

minimum approach airspeed for 0° flaps

VMC visual meteorological conditions

viii

NTSB Aircraft Accident Report

ix

Executive Summary

On January 27, 2009, about 0437 central standard time, an Avions de Transport Régional

Aerospatiale Alenia ATR 42-320, N902FX, operating as Empire Airlines flight 8284, was on an

instrument approach when it crashed short of the runway at Lubbock Preston Smith International

Airport, Lubbock, Texas. The captain sustained serious injuries, and the first officer sustained

minor injuries. The airplane was substantially damaged. The airplane was registered to FedEx

Corporation and operated by Empire Airlines, Inc., as a 14 Code of Federal Regulations Part 121

supplemental cargo flight. The flight departed from Fort Worth Alliance Airport, Fort Worth,

Texas, about 0313. Instrument meteorological conditions prevailed, and an instrument flight

rules flight plan was filed.

The National Transportation Safety Board determines that the probable cause of this

accident was the flight crew’s failure to monitor and maintain a minimum safe airspeed while

executing an instrument approach in icing conditions, which resulted in an aerodynamic stall at

low altitude. Contributing to the accident were 1) the flight crew’s failure to follow published

standard operating procedures in response to a flap anomaly, 2) the captain’s decision to

continue with the unstabilized approach, 3) the flight crew’s poor crew resource management,

and 4) fatigue due to the time of day in which the accident occurred and a cumulative sleep debt,

which likely impaired the captain’s performance.

The safety issues discussed in this report include the flight crew’s actions in response to

the flap anomaly, the continuation of the unstabilized approach, the dispatch of the flight into

freezing drizzle conditions, the efficiency of the emergency response, and simulator-based

training for pilots who fly in icing conditions. Nine safety recommendations are addressed to the

Federal Aviation Administration.

NTSB Aircraft Accident Report

1

1. Factual Information

1.1 History of Flight

On January 27, 2009, about 0437 central standard time,

1

an Avions de Transport

Régional (ATR) Aerospatiale Alenia ATR 42-320 (ATR 42), N902FX, operating as Empire

Airlines flight 8284, was on an instrument approach when it crashed short of the runway at

Lubbock Preston Smith International Airport (LBB), Lubbock, Texas. The captain sustained

serious injuries, and the first officer sustained minor injuries. The airplane was substantially

damaged. The airplane was registered to FedEx Corporation (FedEx) and operated by Empire

Airlines, Inc., as a 14 Code of Federal Regulations (CFR) Part 121 supplemental cargo flight.

The flight departed from Fort Worth Alliance Airport (AFW), Fort Worth, Texas, about 0313.

Instrument meteorological conditions (IMC) prevailed,

2

and an instrument flight rules (IFR)

flight plan was filed.

During the flight’s initial descent to LBB, the first officer was the pilot flying (PF) with

the autopilot system engaged. As the airplane descended from 14,000 to 8,000 feet above mean

sea level (msl), the captain, who was the pilot monitoring (PM), performed the descent and

approach checklists. Review of the cockpit voice recorder (CVR) transcript revealed that the

captain confirmed that the airplane’s anti-icing and deicing protection was set to level 3.

3

The

captain performed the approach briefing,

4

which included what he believed to be the “icing

speed” information (minimum maneuvering and operating airspeeds for approach in icing

conditions).

5

According to the CVR transcript, at 0419:41, the captain briefed the first officer about the

missed approach procedure for the instrument landing system (ILS) approach to runway 17R,

6

stating that “in the event of a miss it’ll be uh climb to thirty seven and a right turn to five

1

All times in this report are central standard time (unless otherwise noted) and based on a 24-hour clock.

2

According to the Federal Aviation Administration (FAA) Pilot/Controller Glossary, IMC is defined as

“meteorological conditions expressed in terms of visibility, distance from cloud, and ceiling [that are] less than the

[minimums] specified for visual meteorological conditions.” At the time of the accident airplane’s approach, LBB’s

ceiling and visibility were below the minimums specified in 14 CFR 91.155 for flight under visual flight rules.

Information obtained from the FAA’s website <http://www.faa.gov/air_traffic/publications/atpubs/PCG/> (accessed

March 21, 2011).

3

The airplane flight manual contained guidelines for using the anti-icing and deicing systems. For more

information, see section 1.17.1.6.

4

During postaccident interviews, the flight crewmembers reported that the captain performed the approach

briefing because they anticipated that he would be flying the approach. They believed that weather conditions were

at the minimums for the approach (ceiling 200 feet above ground level, visibility 1/2 mile), and they were unsure if

the first officer had accumulated the 100 hours of flight time in the ATR 42 required by Empire Airlines for her to

fly the approach to minimums. Subsequently, they learned that the weather conditions were above minimums and

decided that the first officer would fly the approach.

5

For more information about the captain’s approach airspeed briefing and the flight crew’s procedures for

obtaining and using such information, see section 1.17.1.4.

6

According to the CVR transcript, the air traffic controller informed the flight crew that runway 8/26 was

closed and that the localizer back course approach, which the first officer recognized as the only approach for

runway 35L, was unavailable. The flight crew discussed that the winds were from the north but that runway 17R

was the only available option.

NTSB Aircraft Accident Report

2

hundred feet

[7]

via the Lubbock one fourteen radial to HYDRO intersection and hold annnd

[8]

that looks like a parallel entry.” The first officer acknowledged this statement, and the captain

then stated, “climb to thirty seven and a left turn to five out to one fourteen.”

At 0422:32, the LBB approach controller cleared the flight to descend to 6,000 feet msl

and advised that he had not received any icing reports and that the special weather observation

about 0408 indicated winds from 350° at 10 knots (kts), visibility 2 miles in light freezing drizzle

and mist, ceiling overcast at 500 feet above ground level (agl), temperature -8° C, dew point

-9° C, and altimeter setting 30.12 inches of mercury (Hg). At 0424:57, the captain contacted

company flight operations on the radio to advise that the flight was about 15 minutes out.

At 0433:13, the controller cleared the flight for the ILS approach to runway 17R, and at

0433:52, he instructed the flight to contact the LBB tower. The captain established contact with

the tower, and, at 0434:06, the tower controller cleared the flight to land and reported that the

wind was from 010° at 8 kts.

9

During postaccident interviews, both the captain and the first officer stated that the

airplane accumulated ice during the descent. At 0434:24, the first officer called for a flap setting

of 15°, the deployment of the landing gear, and the landing check. During a postaccident

interview, the first officer recalled that the airplane subsequently accelerated in the descent,

which she stated was unusual for the airplane in a flaps- and gear-down configuration. A

postaccident review of information from the airplane’s flight data recorder (FDR) showed that,

after the first officer called for flaps, the airplane’s airspeed remained about 158 kts and briefly

increased to about 160 kts, and the first officer decreased engine power to about 3 percent torque.

At 0435:03, about the time that the first officer reduced engine power, she stated, “what the heck

is going on?” At 0435:04, the captain replied, “you know what? we have no flaps.”

The FDR showed that a flap asymmetry had occurred in which the right flaps did not

extend and the left flaps extended partially (8° to 10°).

10

The autopilot countered the flap

asymmetry by applying aileron deflection that resulted in a 20° left control-wheel movement.

The FDR indicated that, at the time the captain stated that they had “no flaps,” the airplane was

at an altitude of about 1,400 feet agl just outside the locator outer marker (LOM), which serves

as the final approach fix (FAF).

According to the CVR transcript, after the captain commented about the flap problem,

neither crewmember discussed a procedure or checklist to address it. During a postaccident

interview, the first officer stated that she continued to fly the approach with the airplane coupled

to the autopilot while the captain got out a flashlight and tried to troubleshoot the flap problem.

7

The published procedure specified that the initial climb to 3,700 feet msl is followed by a climbing “left” turn

to “5,000 [feet msl]” via the radial to the intersection.

8

The use of excess vowels, letters, or drawn-out syllables in any word in the CVR transcript is intended to

provide a phonetic representation of the word as spoken.

9

According to the ATR 42 Airplane Flight Manual, the maximum allowable tailwind component for landing is

15 kts. The wind recorded about 0430 by the LBB automated surface observing system was from 360° at 14 kts

gusting to 19 kts.

10

All references in this section to airplane configuration, airspeed, altitude agl, and engine power settings are

derived from the airplane performance study. For more information about the study, see section 1.16.1.

NTSB Aircraft Accident Report

3

The captain stated in a postaccident interview that he repositioned the flap handle several times

and used the flashlight to check the circuit breakers behind the first officer’s seat. The captain

stated that, after finding that no circuit breakers were out, he moved the flap handle back to the

“up” (or 0°) position because he did not want the flaps to travel inadvertently during the

approach.

The FDR indicated that, between 0434:58 and 0435:25, as the airplane descended with

the autopilot engaged, its airspeed decreased from about 160 to 125 kts. At 0435:30 (about

26 seconds after the captain commented about the flap anomaly), the CVR captured a sound

consistent with the aural stall warning (“cricket”) and the tactile stick shaker that lasted

1.1 second. The captain stated to the first officer, “yeah don’t do that.” At 0435:32, a 0.3-second

sound consistent with the aural stall warning sounded. At 0435:36, the captain stated, “just keep

flying the airplane. okay.” The FDR indicated that the stick-shaker activation disconnected the

autopilot when the airplane was about 900 feet agl at 125 kts indicated airspeed (KIAS).

11

The

FDR also indicated that the first officer increased engine power to about 70 percent torque and

began manually flying the approach. Following the application of power, the airspeed began

increasing. At 0435:40, the first officer asked, “should I go around,” and the captain replied,

“no,” and then stated, “keep descending.”

At 0435:44, the first officer stated, “we’re getting close here”; the CVR transcript

indicated that the first officer’s voice sounded as if she were straining. During a postaccident

interview, the captain stated that he looked over and was surprised to see that the first officer was

manually flying the approach and that he had not heard the aural alert to indicate that the

autopilot had been disconnected (no alert was captured by the CVR). The captain asked the first

officer if she wanted him to finish the approach; the first officer replied, “yes please.”

At 0435:50, the captain took control as the PF when the airplane was about 700 feet agl at

143 KIAS. During a postaccident interview, the captain stated that the airplane was high and to

the right of the approach course and that he corrected to put it back on course. According to the

FDR, at 0435:56, the captain reduced the engine power to about 10 percent torque. At 0436:00,

the CVR captured a 0.9-second sound consistent with the aural stall warning and the stick shaker

concurrent with the terrain awareness and warning system (TAWS) warning, “pull up. pull up.”

According to the FDR, at this time, the airplane was about 500 feet agl at 156 KIAS. At 0436:04,

the first officer stated, “there’s the runway.”

Between 0436:00 and 0436:17, as the airplane continued to descend, its airspeed

decreased from about 156 to 129 kts. At 0436:17, the captain called for maximum propeller

speed. At 0436:19, when the airplane was about 200 feet agl at 124 KIAS, the CVR captured the

sounds of engine power increasing concurrent with the aural stall warning and the stick shaker.

At 0436:21, the airplane was about 150 feet agl at 123 KIAS and began to roll right-wing-down

(RWD).

Between 0436:21 and 0436:23, the airplane rolled right to a bank angle of 35° RWD. The

airplane then rolled left to a bank angle of 50° left-wing-down (LWD) bank, and then right

11

The published minimum airspeed for the airplane flying with the flaps retracted in icing conditions was

143 KIAS.

NTSB Aircraft Accident Report

4

reaching a 10° RWD bank before it impacted the ground. At 0436:27, the CVR captured the

sound of impact. During a postaccident interview, the captain reported that he had no lateral

control of the airplane and that the controls were almost “snatched” out of his hands.

An airport operations agent in a vehicle on taxiway M, which parallels runway 17R/35L,

was about 1,800 feet south of the approach end of runway 17R when he saw the airplane

approach. He estimated that the airplane was about 400 to 500 feet agl when it emerged from the

fog layer and stated that it appeared to be high and to the right of the runway centerline. He

stated that the airplane appeared to be “pancaking” in its descent and that it rolled slightly to the

right, then rolled hard to the left in a near-90° bank, then rolled back to the right, impacted the

ground, and slid for a distance. He further stated that, as the airplane slid past his position, a fire

erupted on the airplane’s right wing and “engulfed” the airplane. He stated that he immediately

notified his supervisor of the accident and that he could hear the beeping tones of the crash

phone over his radio as the airplane continued to slide. He stated that he soon saw the lights of

the aircraft rescue and firefighting (ARFF) units emerging from their station.

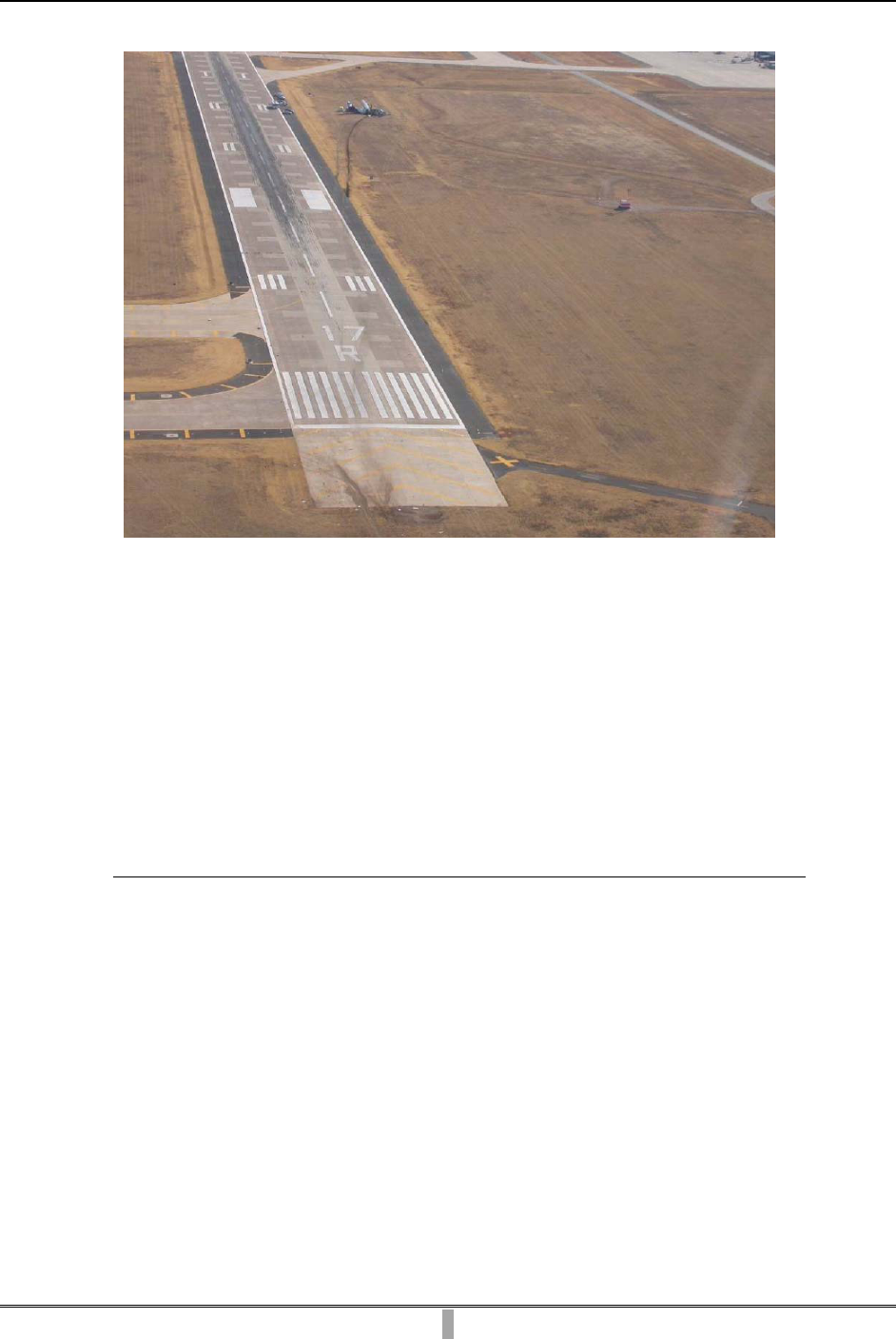

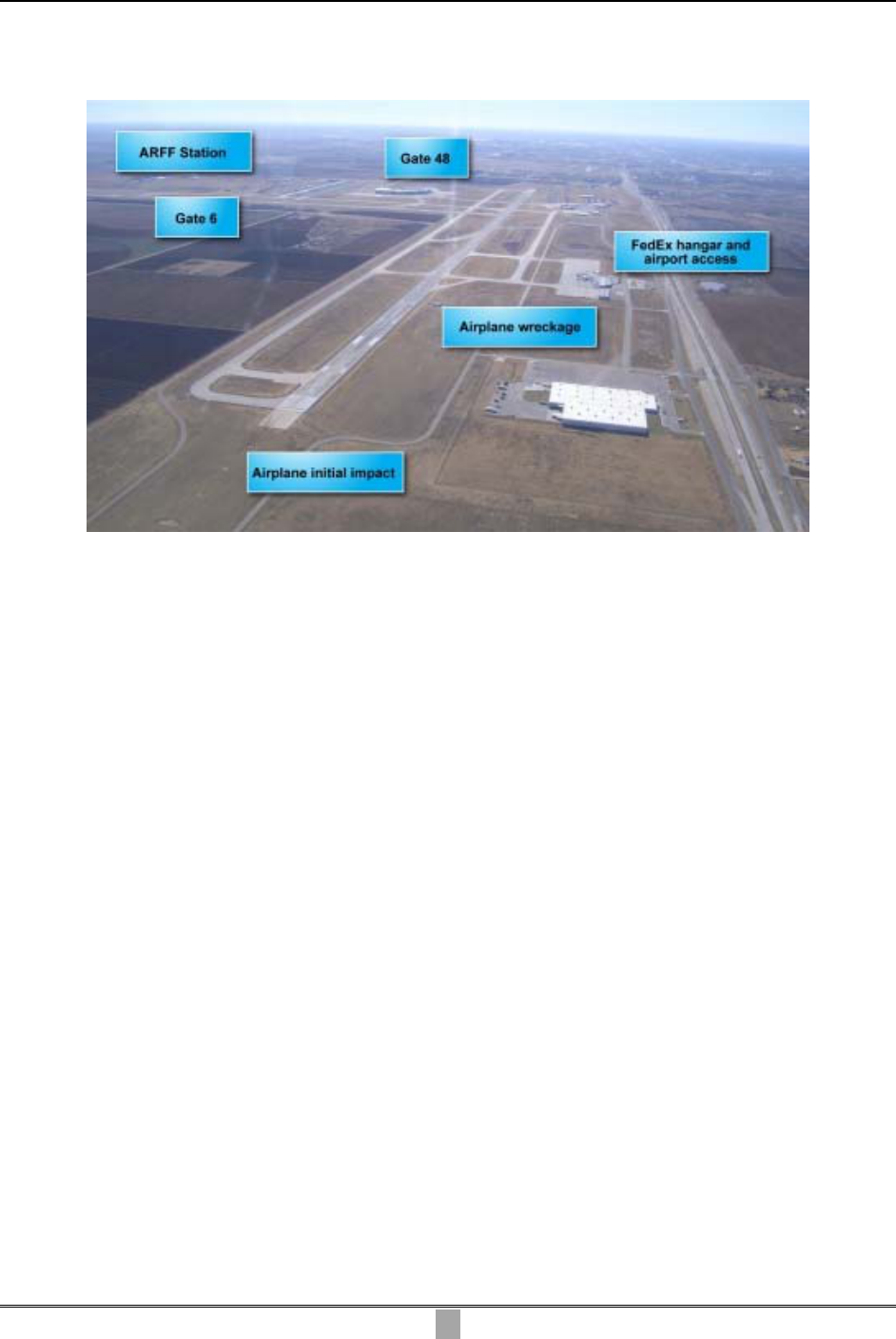

The airplane came to rest next to the right side of the runway (about 200 feet west of the

runway centerline), north of taxiway S. Figure 1 is an aerial view of the approach end of

runway 17R and the location of the wreckage. The ARFF units, which were on the accident

scene within about 4 minutes, were the first responders to arrive. The ARFF response was joined

by Lubbock Fire Department units, one of which could not enter at the designated airport access

gate because the gate would not open; the unit was diverted to a different gate to enter the

airport.

12

12

For more information about the emergency response, see section 1.15.2.

NTSB Aircraft Accident Report

Figure 1. Aerial view of approach end of runway 17R and location of wreckage.

1.2 Injuries to Persons

Table. Injury Chart

Injuries Flight Crew Cabin Crew Passengers Other Total

Fatal

0 0 0 0 0

Serious

1 0 0 0 1

Minor

1 0 0 0 1

None

0 0 0 0 0

Total

2 0 0 0 2

1.3 Damage to Airplane

The airplane was substantially damaged by the impact forces and postcrash fire.

1.4 Other Damage

The airport approach lighting system and the runway were damaged during the accident

sequence.

5

NTSB Aircraft Accident Report

1.5 Personnel Information

1.5.1 The Captain

The captain, age 52, held an airline transport pilot certificate with ratings for

single-engine and multiengine land airplanes. His most recent Federal Aviation Administration

(FAA) first-class medical certificate was issued on September 19, 2008, with a limitation that he

must “possess glasses for near/intermediate vision.” According to Empire Airlines’ records, the

captain had accumulated 13,935 total flight hours, including 12,742 hours as pilot-in-command

(PIC). He had a total time in the ATR 42 of 2,052 hours, 1,896 hours of which were as PIC. In

the 90 days, 30 days, and 24 hours before the accident, the captain accumulated about 53, 13, and

5 hours, respectively.

The captain was hired by Empire Airlines on May 9, 1988. Employee training records

showed that the captain had previously flown and served as a check airman on the company’s

Cessna 208 (single-engine, turbopropeller-powered) airplanes, in which he had accumulated

about 6,600 total flight hours. He had also previously flown the company’s Fokker F27

(multiengine, turbopropeller-powered) airplanes, in which he had accumulated about 2,500 total

flight hours, about 1,900 hours of which were as PIC. Employee training records showed that the

captain completed his most recent recurrent proficiency check ride and line check on

September 22, 2008. His most recent recurrent ground training, which focused on ATR 42

systems, was completed on March 29, 2008. A review of FAA and company records revealed

that the captain had no previous FAA enforcement actions, incidents, or accidents.

The captain was experienced with in-flight icing conditions because he had worked as a

pilot in the Pacific Northwest and Alaska for 30 years. He stated that he had been dispatched into

freezing drizzle before and that, while flying in such conditions, he maintained a heightened

awareness of the flying environment.

The first officer described the captain as someone whom she would feel comfortable

speaking up to, if necessary. She stated that the captain sought her input and asked for her

opinion and that, at the beginning of their trip pairing, the captain told her that she should tell

him if she saw him do anything wrong. Other Empire Airlines’ pilots who had flown with the

captain stated that his greatest strength as a pilot was his experience level. One pilot stated that

the captain occasionally cut corners, seemed rushed, was less thorough on briefings than other

captains, and became easily agitated when flying and driving.

1.5.2 The First Officer

The first officer, age 26, held a commercial pilot certificate with ratings for single-engine

and multiengine land and instrument airplanes. Her most recent FAA first-class medical

certificate was issued on December 4, 2008, with no limitations. According to Empire Airlines’

records, the first officer had accumulated 2,109 total flight hours, about 1,890 hours of which

were as PIC. She had accumulated 130 hours in the ATR 42 as second-in-command (SIC). In the

90 days, 30 days, and 24 hours before the accident, the first officer accumulated about 88, 29,

and 5 hours, respectively.

6

NTSB Aircraft Accident Report

The first officer was hired by Empire Airlines on July 25, 2008. Employee training

records showed that the first officer completed her most recent proficiency check ride (an initial

check) on September 10, 2008. Her most recent ground training, which was initial training for

the ATR 42, was completed on August 29, 2008. A review of FAA and company records

revealed that the first officer had no previous FAA enforcement actions, incidents, or accidents.

The first officer had limited experience flying in icing conditions before working for

Empire Airlines, and the ATR 42 was the first airplane in which she had flown that was equipped

with deicing and anti-icing systems.

Other Empire Airlines pilots who had flown with the first officer described her flying

skills as “at par” or “average” compared to other first officers with the same experience level.

One pilot stated that the first officer was methodical about using checklists. Another pilot stated

that the first officer’s greatest strength as a pilot was that she was “nonconfrontational.” One

captain described the first officer’s crew resource management (CRM) skills as “good,” and

another captain stated that the first officer did not seem to have a problem speaking up, if

needed. Regarding areas in which the first officer could improve, one pilot stated that “she could

employ the skills she already knew without asking so many questions,” and another pilot stated,

“more hands-on flying of the airplane.”

1.5.3 Flight Crew’s Rest Opportunities

1.5.3.1 The Captain

The captain reported that, on January 24, 2009, he awoke about 0800. From about 1015

to 1535, he traveled as a passenger on commercial flights to reposition from his home in

Portland, Oregon, to Midland International Airport (MAF), Midland, Texas. The captain went to

bed about 2200 in his hotel room in Midland, Texas. On January 25, 2009, the captain awoke

about 0800, performed various activities throughout the day (including exercising, reading,

shopping, and going to dinner at a coworker’s home with the first officer), and went to bed about

2200.

The captain stated that, on January 26, 2009, he awoke about 0400 to prepare for the

upcoming night flight. He performed various activities and then slept from about 1100 to 1630.

He stated that he met the first officer in the hotel lobby about 1820 and that they drove to MAF

to begin duty about 1845. They departed MAF about 1945, arriving at El Paso International

Airport (ELP), El Paso, Texas, about 2115. They subsequently departed ELP for AFW about

2230, arriving about 0030 on January 27, 2009. The flight crew then departed AFW for LBB (the

accident flight) about 0313.

During postaccident interviews, the captain indicated that he needed 6 to 8 hours of sleep

per night to feel rested. He stated that he considered himself to be a night person and that he felt

rested before the accident flight. He described his workload on the day of the accident as normal

overall but stated that, during the approach, the workload was high. The captain stated that

takeoffs and landings were high-workload situations and that the icing conditions and flap

anomaly elevated his workload.

7

NTSB Aircraft Accident Report

8

1.5.3.2 The First Officer

The first officer (who was based in Salt Lake City, Utah)

13

had first arrived in Midland,

Texas, on January 18, 2009, to fly a trip sequence with another captain and had completed that

trip sequence on January 23, 2009. During those trips, the first officer was on duty during night

hours beginning about 0045. After the first officer completed that trip sequence, Empire Airlines

paid the expenses for the first officer to spend the weekend in Midland, Texas, rather than have

her commute home on a short turnaround. The first officer indicated that she was off duty from

the afternoon of January 24, 2009, until the evening of the accident flight. The first officer

indicated that, because her previous trip sequence and the accident trip sequence required her to

sleep during the day and be awake at night, she maintained that same sleep schedule during her

off-duty time (between the two trip sequences) in Midland, Texas.

On January 24, 2009, the first officer went to bed about 0600 in her hotel room and

awoke about 1430. She then performed various activities throughout the day and evening

(including exercising and going to the store) and went to bed about 0600 on January 25, 2009.

She awoke about 1400, later met the captain to go to dinner at a coworker’s home, returned to

the hotel about 2200, and went to bed sometime in the morning on January 26, 2009. The first

officer awoke about 1500 and reported for her trip duty with the captain about 1845.

During postaccident interviews, the first officer indicated that she needed 7 hours of sleep

to feel rested. She stated that she considered herself to be a night person and that she felt rested

before the accident flight. She described her workload on the day of the accident as normal but

stated that the workload became high when she and the captain realized that the flaps did not

function properly. The first officer stated that although the workload during the approach was

high, she felt that it was something that they could handle.

1.6 Airplane Information

1.6.1 General

The accident airplane (model ATR 42-320, serial number [SN] 175) received its

airworthiness certificate in 1990. In 2005, the airplane was configured for freight operations in

accordance with supplemental type certificate (STC) ST01189W1.

14

The airplane was powered

by two Pratt & Whitney Canada PW 121 engines, each equipped with a Hamilton Standard 14SF

propeller. According to the type certificate data sheet, the ATR 42 is certificated for flight in

known icing conditions in accordance with 14 CFR Part 25, Appendix C, which details the types

of icing exposures for which the aircraft is tested and certificated. The airplane’s most recent

inspection (a 2-month inspection) was completed on January 9, 2009. At the time of the accident,

the airplane had accumulated 28,768 hours of operating time and 32,379 cycles.

13

Salt Lake City, Utah, was a “floater” base for Empire Airlines. Flight crews based there would commute to

various cities based on the company’s needs and at the company’s expense.

14

STC ST01189W1 is held by M7 Aerospace LP.

NTSB Aircraft Accident Report

9

The airplane had no deferred maintenance items, and the maintenance records showed

compliance with all applicable airworthiness directives (ADs) for the airframe, propeller

subassemblies, and the right engine.

15

The AD tracking form for the left engine was not located.

During the investigation, an Empire Airlines records clerk located work orders and records of

other required directives to demonstrate AD compliance for the left engine.

The airplane’s maximum gross takeoff and landing weights were 37,258 and

36,155 pounds (lbs), respectively. A review of the FedEx Feeder Aircraft Load Control Sheet

and the Empire Airlines Cargo Load Manifest for the flight revealed that the accident flight’s

calculated takeoff and estimated landing weights were 34,487 and 32,717 lbs, respectively, and

that its calculated center of gravity (CG) was within limits.

1.6.2 Flap System

The ATR 42 is equipped with four trailing-edge flaps (two per wing) that are electrically

controlled and hydraulically operated (each flap has a hydraulic actuator). The flight crew can

command the flaps into four positions using the cockpit flap control lever: 0° for cruise flight,

15° for takeoff and approach, 30° for landing, and 45° for use during an emergency.

16

During

normal operations, all flaps move together when commanded.

An interconnection torque shaft is connected to the left and right inboard flaps. Both a

flap position transmitter, which provides flap position information to the flap indicator in the

cockpit, and a flap asymmetry detector are attached to the interconnection torque shaft. The flap

position transmitter is mounted near the center of the interconnection torque shaft and senses the

average position of the flaps based on movement of the torque shaft. The flap asymmetry

detector is designed to prevent any asymmetry between the right and left flaps from exceeding 8°

to 10° (the precise value depends upon the flap positions when the asymmetry occurs). If a flap

asymmetry reaches the determined value, a microswitch integrated into the detector cuts off the

electrical power supply to the flap control switch, and the flap extension or retraction solenoid is

no longer energized. As a result, the flaps will stop in the positions reached at the time of the

power interruption. Once this occurs, the flaps will not move in response to movement of the flap

control lever in the cockpit until maintenance personnel reset the system on the ground.

17

If a flap asymmetry occurs due to a restriction (jam) and the restriction is then removed,

hydraulic pressure in the system will move the flaps to a symmetrical position. The resulting flap

position will be the average of the right and left flap positions when the asymmetry occurred.

Even if such hydraulic balancing of the flaps occurs, post-flight maintenance action would still

be required to restore electrical power to the flap control switch.

15

The airframe AD compliance records were located throughout the airplane’s records, the propeller

subassembly ADs were tracked through Empire Airlines’ computerized maintenance tracking system, and the right

engine ADs were listed on an AD tracking form located with the right engine logbooks.

16

The four flap positions are standard increments. In the ATR 42, for some selected settings, the actual position

of the flaps differs by a few degrees from the indicator increment (the 30° flap position increment represents 27° of

actual flap deflection).

17

For more information about the flight crew’s procedures for responding to a flap asymmetry, see

section 1.17.1.1.

NTSB Aircraft Accident Report

A flap position indicator in the cockpit has an index marked with the four flap positions

(shown as 0°, 15°, 30°, and 45°), and a needle pointer indicates the flap position on the index. If

a flap asymmetry occurs, the flap indicator needle in the cockpit will point to the index value that

corresponds with the average position of the flaps. Figure 2 shows the flap position indicator,

and the inset depicts the likely needle pointer position during the flap asymmetry.

Figure 2. Flap position indicator. Inset shows the likely needle pointer position during the flap

asymmetry.

In addition to the cockpit flap position indicator, exterior flap position fairings mounted

on the wings (one per wing) are visible to each flight crewmember through their respective side

windows. These fairings are also marked with lines and numbers for the four flap positions,

providing flight crews with a visual indication of the actual position of each flap. Figure 3 shows

the exterior flap position fairing. The wing flap position fairings are illuminated by the wing

lights during nighttime use. If a flap asymmetry occurs, the actual positions of the right and left

flaps will be indicated on the respective flap position fairings.

Figure 3. Exterior flap position fairing.

10

NTSB Aircraft Accident Report

11

1.6.3 Deicing, Anti-Icing, and Anti-Icing Advisory Systems

The ATR 42’s ice protection system permits the airplane to operate in some atmospheric

icing conditions (applicable restrictions are noted in the limitations section of the airplane flight

manual [AFM]).

18

The leading edges of the ATR 42’s wings, horizontal stabilizers, and vertical

stabilizer are equipped with pneumatic deice boots that are inflated by engine compressor bleed

air.

19

When the flight crew selects airframe pneumatic boot use, pockets in the boot system

inflate in sequence, perpendicular to the airfoil, to deice the leading edges.

The propeller blades, windshields, probes (pitot, static, air temperature, and

angle-of-attack [AOA]), and flight control horns

20

are electrically heated. The horn anti-icing

feature prevents ice deposits from forming between the wing structure and the moving parts of

the control surfaces. A pneumatic system provides deicing protection for the engine intakes and

is designed to prevent a reduction or total loss of engine performance in icing conditions.

According to the ATR 42 flight crew operating manual (FCOM), the ATR 42 has an

anti-icing advisory system (AAS) designed to alert the flight crew to apply the correct

procedures when flying in icing conditions.

21

The AAS includes an ice detector (mounted under

the left wing) and three cockpit light annunciators; the amber ICING light and green ICING

AOA light are on the central panel, and the blue DEICING light is on the memo panel. The AAS

alerts the flight crew as soon as (and as long as) the ice detector detects ice accretion. Once the

probe detects at least 0.5 millimeter of ice, the amber ICING light illuminates. The AAS

self-tests continuously, and any failure illuminates a FAULT light with a single chime.

1.6.4 Flight Instruments

1.6.4.1 Airspeed Indicator

The ATR 42 is equipped with three analog airspeed indicators (one on each pilot’s

instrument panel and one on the central panel). Each airspeed indicator has a moving needle

pointer that indicates the airplane’s KIAS on a fixed scale that shows 60 to 400 kts. Each

airspeed indicator has four moveable indices, known as “bugs” (one internal and three external),

on the outer scale that the pilot uses to manually set certain airspeed references for takeoff or

landing, based on airplane performance information for the flight conditions.

22

The internal bug, which is underneath the glass face of the airspeed indicator, is set by the

pilot using a selector knob. According to the ATR 42 pilot handbook, for approach and landing

in icing conditions, the internal bug should be set to V

mHB

30 icing, which is the minimum

18

For more information about these restrictions, see section 1.17.1.6.

19

The vertical stabilizer deice boots are optional on ATR 42s.

20

The airplane’s primary flight controls (ailerons, elevators, and rudder) are mechanically operated and have

counterweights, or horns, that serve to balance the controls.

21

For information about flight crew procedures for responding to each AAS annunciator, see section 1.17.1.6.

22

For information about obtaining applicable airspeed references and setting the bugs, see section 1.17.1.4.

NTSB Aircraft Accident Report

12

approach airspeed and target touchdown airspeed with 30° flaps in icing conditions.

23

The

airspeed indicated by the internal bug (as selected by the pilot using the selector knob) controls

the reference on the electronic attitude direction indicator (EADI) fast/slow scale.

24

The other three indices, which are located on the outside of the glass face of the airspeed

indicator, are color coded for use in referencing certain airspeeds during takeoff or landing and

are manually positioned by the pilot. Unlike the internal bug’s function, the pilot’s positioning of

these three indices (yellow, white, and red) does not affect any other systems or displays. The

ATR 42 pilot handbook states that, for an approach, the yellow bug should be set to reference

V

ga

, which is the approach airspeed for 30° flaps plus 5 kts (not corrected for wind effect).

25

Similarly, the white bug should be set to reference V

mLB

0 normal, which is the minimum

airspeed for an approach with 0° flaps in nonicing conditions, and the red bug should be set to

reference V

mLB

0 icing, which is the minimum airspeed for an approach with 0° flaps in icing

conditions. Figure 4 is an airspeed indicator showing the needle pointer; selector knob; and

internal, yellow, white, and red bugs.

Figure 4. Airspeed indicator showing needle pointer; selector knob; and internal, yellow, white,

and red bugs.

23

The ATR 42 pilot handbook notes that this speed is to be corrected for wind and that the wind factor is 1/3 of

the headwind velocity or the gust in full, with a maximum wind factor of 15 kts.

24

For more information, see section 1.6.4.2.

25

The ATR 42 pilot handbook states that for V

ga

, pilots should use the higher of V

mHB

30 + 5 kts (not corrected

for wind) or 1.1 V

mca

(1.1 times the minimum control airspeed with 5° of bank and the failure of the critical engine

with takeoff flap and landing gear retracted).

NTSB Aircraft Accident Report

13

1.6.4.2 Electronic Flight Information System

The airplane’s electronic flight information system includes displays for each pilot on the

cockpit instrument panel. Each pilot’s display includes an EADI to indicate the airplane’s pitch

and roll relative to the horizon. The EADI depicts the horizon as a straight, horizontal line

between the blue upper half of the display (showing the relative location of the sky), and the

brown lower half (showing the relative location of the ground). The pitch scale is marked in 5°

intervals, and the roll scale indicates select bank angles between 0° and 60°.

The left side of each EADI also displays a “fast/slow” scale that indicates the difference

between the airplane’s actual airspeed and the target airspeed as selected by the pilot using the

internal bug on the airspeed indicator. An index on the fast/slow scale moves up (fast) or down

(slow) according to any deviation of the actual airspeed from the selected airspeed.

1.6.5 Automatic Flight Control System

The airplane was equipped with an automatic flight control system that provided

autopilot, yaw damper, flight director, and altitude alert functions. The autopilot system is

designed to automatically disconnect when certain system conditions occur, including achieving

the stall warning threshold. If an autopilot disconnect occurs (either automatically or manually),

indications provided to the flight crew include an aural alert (“cavalry charge” tone),

26

a message

(“AP DISENGAGED”) on the advisory display unit (ADU), and a visual annunciator (“AP

MSG”) on the primary flight display. With the autopilot system engaged, if an anomaly in the

airplane’s roll characteristics occurs (such as those that a flap asymmetry would induce), the

ADU will show “RETRIM ROLL R [or L] WING DN” and “AILERON MISTRIM” messages.

1.6.6 Stall Protection System

The airplane’s stall protection system includes two AOA probes (one on each side of the

forward fuselage) that detect the airplane’s AOA, an aural stall warning (“cricket”), a tactile stick

shaker, and a stick pusher. According to ATR, when the airplane is configured for flight in

nonicing conditions with flaps 0°, if the AOA probes detect that the airplane has reached a

critical AOA of 11.6°, the aural stall warning sounds, and the stick shaker activates. If the probes

detect that the AOA continues to increase, the stick pusher activates between 11.5° and 13.8°,

depending on the AOA’s rate of change.

The stall protection system is designed to provide an earlier stall warning threshold

during flight in icing conditions. According to ATR, when the airplane is configured with the

control horns’ anti-icing selected on with flaps 0°, the critical AOA for activation of the aural

stall warning and the stick shaker is reduced to 7°, and the stick-pusher activation remains at an

angle between 11.5° and 13.8°.

26

The aural warning can be inhibited by other aural warnings with higher priority.

NTSB Aircraft Accident Report

14

1.7 Meteorological Information

Freezing precipitation in the form of light freezing rain and ice pellets began at LBB

about 2300 on January 26, 2009. The precipitation later changed to light freezing drizzle, which

continued until after the accident.

27

The LBB weather observation about 0353 reported wind from 010° at 14 knots, visibility

3 miles in light freezing drizzle and mist, ceiling overcast at 500 feet agl, temperature -8° C, dew

point -9° C, and an altimeter setting 30.13 inches of Hg. The LBB weather observation about

0453 reported wind from 020° true at 13 kts gusting to 18 kts, visibility 2 miles in light freezing

drizzle and mist, ceiling overcast at 500 feet agl, temperature -8° C, dew point -9° C, and an

altimeter setting 30.13 inches of Hg. The remarks section of the weather observation indicated

that the ceiling was variable from 400 to 900 feet agl and that the hourly liquid equivalent

precipitation was less than 0.01 inch (a trace of precipitation).

The National Weather Service (NWS) terminal aerodrome forecast for LBB expected

IFR conditions to prevail during the period including the accident flight’s arrival with wind from

030° at 12 knots, visibility of 1 1/2 miles in light freezing drizzle and mist, and ceiling overcast

at 100 feet agl through about 0800, with a temporary period of visibility 1/2 mile in light freezing

drizzle and freezing fog. The NWS also had issued an airmen’s meteorological information

(AIRMET) for moderate icing conditions

28

from the freezing level through 22,000 feet msl over

Texas that was current at the time of the accident. A review of the NWS current icing potential

and supercooled large droplet (SLD) icing diagnostic charts indicated a greater-than-80-percent

probability of icing conditions over the LBB area from the surface through 6,000 feet msl and a

high likelihood of encountering SLD conditions. Temperatures were above freezing between

6,000 and 11,000 feet msl as a result of a temperature inversion.

1.8 Aids to Navigation

No problems with any navigational aids were reported.

27

As defined by the American Meteorological Society Glossary and the National Weather Service Federal

Meteorological Handbook, freezing drizzle is drizzle that falls in liquid form but freezes upon impact with surfaces

to form a coating of glaze; freezing drizzle has a diameter between 0.05 to 0.5 millimeters (0.002 to 0.02 inches) at

temperatures less than 0° C.

28

According to the FAA’s Aeronautical Information Manual (AIM), when reporting icing to air traffic control,

pilots should describe the icing intensity as moderate when the rate of accumulation is such that even short

encounters become potentially hazardous and use of deicing/anti-icing equipment or flight diversion is necessary.

Information obtained from the FAA’s website <http://www.faa.gov/air_traffic/publications/ATpubs/AIM/>

(accessed March 21, 2011). FAA Advisory Circular 91-74A, “Pilot Guide: Flight In Icing Conditions” published in

December 2007, states that, in icing of moderate intensity, “the rate of ice accumulation requires frequent cycling of

manual deicing systems to minimize ice accretions on the airframe. A representative accretion rate for reference

purposes is 1 to 3 inches (2.5 to 7.5 cm) per hour on the outer wing. The pilot should consider exiting the condition

as soon as possible.”

NTSB Aircraft Accident Report

15

1.9 Communications

No problems with any communications equipment during the flight were reported.

During a postaccident interview, the first officer stated that, after the accident, the captain

attempted to contact the air traffic control tower (ATCT) using the airplane’s radios but that the

radios were inoperative. The CVR transcript indicates that the CVR captured the sound of impact

at 0436:27, a subsequent sound similar to occupants moving around in the cockpit, the captain’s

instructions about exiting the airplane, and the sound of the door opening at 0437:25. No further

sounds were captured, and the recording ended at 0441:35.

1.10 Airport Information

LBB is located about 4 miles north of the city of Lubbock, Texas, at an elevation of

3,282 feet msl. LBB is a Class I public airport certificated under 14 CFR Part 139.

29

Runway

17R/35L, which is the longest of the airport’s three runways,

30

has a concrete surface and is

11,500 feet long and 150 feet wide.

LBB maintained ARFF capabilities at Index C

31

and had four vehicles, three of which

(Rescue 1, 2, and 4) were equipped with a roof turret, bumper turret, and hand line; each vehicle

carried 1,500 gallons of water, at least 190 gallons of aqueous film forming foam (AFFF), and

450 lbs of dry chemical. The remaining vehicle (Rescue 5), which was equipped with a hand

line, carried 450 lbs of dry chemical and 100 gallons of a mixture of water and AFFF. The ARFF

station was centrally located south of taxiway J near the midpoint of runway 8/26. ARFF

services were available 24 hours a day, every day, and the station was staffed by a minimum of

four firefighters. Five firefighters, all of whom participated in the response, were on duty at the

time of the accident.

32

1.10.1 Emergency Plan

LBB had an FAA-approved airport emergency plan (AEP) that provided guidance

intended to minimize the possibility and extent of personal injury and property damage during an

emergency. The FAA approved the most recent revisions to the AEP on July 9, 2008. The AEP

stated that, during an emergency response, “primary entry points to the airfield by responding

units will be at Gate 6 and Gate 48 or at a location prescribed by the command post.” The AEP

stated that “the Battalion Chief will set up the initial staging area/command post near Gate 6,

Gate 48, or another designated area.”

29

Title 14 CFR 139.5 states that a Class I airport is certificated to serve scheduled operations of large air carrier

aircraft and can also serve unscheduled passenger operations of large air carrier aircraft and/or scheduled operations

of small air carrier aircraft.

30

Runway 8/26, which has a concrete surface, is 8,001 feet long and 150 feet wide, and runway 17L/35R,

which has an asphalt surface, is 2,891 feet long and 75 feet wide.

31

LBB was an Index C airport based on five or more average daily departures of aircraft with a length of at

least 126 feet but less than 159 feet, as defined in 14 CFR 139.315. For an airport to meet Index C capabilities,

14 CFR 139.317 requires two or three ARFF vehicles that contain at least the minimum specified amount of various

extinguishing agents.

32

For more information about the emergency response, see section 1.15.2.

NTSB Aircraft Accident Report

16

If an accident occurs, the ATCT notifies the ARFF station through the direct line radio to

the station. According to the letter of agreement between the LBB ATCT and the City of

Lubbock, upon the alert activation, the ATCT controller should provide, “as is available,” the

“type of aircraft, nature of the emergency, runway to be used, and any other information if time

permits.”

1.10.2 Snow and Ice Control Plan

As required by 14 CFR 139.313, LBB maintained an FAA-approved snow and ice

control plan. According to the airport’s snow and ice operations document, the operations

supervisor, operations agent on duty, or maintenance supervisor is responsible for monitoring the

runway and taxiway environment to determine when snow and ice removal is needed. Sensors

embedded at various points on the runways, taxiways, and the terminal ramp detect surface and

subpavement temperatures and surface moisture, and information from the sensors is monitored

from the airfield maintenance building by airport maintenance personnel.

The snow and ice operations document indicated that, during critical temperatures, if

moisture or precipitation is occurring or is expected to occur, granulated urea will be applied to

the first priority airport operational surfaces, such as the active runway, its parallel taxiway,

taxiways connecting the active runway to the terminal ramp, and the established ARFF road

from the fire station to taxiway J. The assistant airport manager stated that the road from the fire

station to taxiway J had received a urea application before the accident flight’s arrival. No

written record exists to indicate when this application occurred.

The snow and ice operations plan did not address monitoring or ensuring the operability

of the airport emergency response and mutual aid gates. FAA Advisory Circular (AC)

150/5200-30C, “Airport Winter Safety and Operations,” which provides guidance to assist

airport operators in developing a snow and ice control plan, also did not address this topic. An

informal survey of other 14 CFR Part 139 airports where operations are affected by winter

weather revealed that none of the airports’ snow and ice control plans addressed gate operability.

1.11 Flight Recorders

1.11.1 Cockpit Voice Recorder

The accident airplane was equipped with a Fairchild Model A100A CVR, SN 59653,

capable of recording four channels of analog audio on a continuous loop tape. An examination of

the CVR at the National Transportation Safety Board’s (NTSB) vehicle recorders laboratory

found no evidence of structural or heat damage, and audio information was extracted without

difficulty.

The extracted 30-minute, 43-second recording consisted of three channels of useable

audio information that captured events from before the flight’s descent to several minutes after

the accident. Excellent quality audio

33

was obtained from the channels for the captain’s and the

33

In an excellent quality recording, virtually all of the crew conversations can be accurately and easily

understood, and only one or two words are not intelligible; any loss is usually attributed to simultaneous cockpit

NTSB Aircraft Accident Report

17

first officer’s audio panels, and good quality audio was obtained from the channel for the cockpit

area microphone. The fourth channel (the use of which was not required by Federal regulations)

contained no audio information.

1.11.2 Flight Data Recorder

The accident airplane was equipped with a Fairchild Model FA2100 FDR, SN 289112.

The FDR was sent to the NTSB’s laboratory for readout and evaluation; it was received in good

condition, and the data were extracted normally from the recorder. The FDR recorded about

56 hours of data, and the accident flight is reflected in the final 2 hours 18 minutes of the

recording. The FDR system was configured to record more than 70 parameters of airplane flight

information in a digital format using solid-state flash memory as the recording medium. For this

investigation, 58 parameters that were considered relevant were verified and examined. The

relevant parameters included flap position, flap asymmetry, left and right aileron surface

positions, KIAS, glideslope and localizer deviations, radio altitude (altitude as sensed by the

radio altimeter), AOA, roll, pitch, pitch trim, right control column position, control wheel

position, airframe deicing, left and right elevator positions, and left and right engine propeller

speed.

34

1.12 Wreckage and Impact Information

Examination of the accident site showed that the airplane initially impacted flat, grassy

terrain about 300 feet north of the runway 17R blast pad.

35

Ground scars and debris from the

airplane extended about 2,500 feet south from that location to where the main wreckage came to

rest next to the right side of the runway (about 200 feet west of the runway centerline), north of

taxiway S. Fragments of the nose landing gear, right main landing gear, and a separated outboard

section of the right aileron were identified in the initial debris field near the beginning of the

runway.

Examination of the wreckage found that the airplane was resting on its nose section and

leaning to the right; the left main landing gear remained attached. Sections of the upper fuselage,

right wing, and right inboard and outboard flaps were destroyed by fire. The left engine remained

secured to the wing, and the left propeller sustained minimal damage. The right engine and the

right propeller sustained impact and fire damage.

conversations and/or radio transmissions that obscure each other. In a good quality recording, most of the crew

conversations can be accurately and easily understood, but several words or phrases are not intelligible; any loss can

be attributed to minor technical deficiencies, momentary dropouts in the recording system, or a large number of

simultaneous cockpit conversations and/or radio transmissions that obscure each other.

34

For information regarding the relevant parameters that were used in performing the airplane performance

study, see section 1.16.1.

35

A blast pad, which is unusable for landing, takeoff, or taxiing, is designed to eliminate the erosive effect of

the high wind forces produced by airplanes at the beginning of their takeoff roll. The blast pad for runway 17R is a