JANUARY 2010

Energy Efficiency &

Renewable Energy

2008 SOLAR TECHNOLOGIES

MARKET REPORT

i

Table of Contents

Table of Contents ........................................................................................................................... i

Figures ........................................................................................................................................... iii

Tables ............................................................................................................................................. v

Acknowledgments ........................................................................................................................ vi

List of Acronyms ......................................................................................................................... vii

Executive Summary ..................................................................................................................... ix

Notes .............................................................................................................................................. xi

1. Installation Trends, Photovoltaic and Concentrating Solar Power ..................................... 1

1.1 Global Installed PV Capacity................................................................................................ 1

1.1.1 Cumulative Installed PV Capacity Worldwide .................................................................. 1

1.1.2 Growth in Cumulative and Annual Installed PV Capacity Worldwide ............................. 2

1.1.3 Worldwide PV Installations by Interconnection Status and Application .......................... 4

1.2 U.S. Installed PV Capacity ................................................................................................... 6

1.2.1 Cumulative U.S. Installed PV Capacity ............................................................................. 6

1.2.2 U.S. PV Installations by Interconnection Status ................................................................ 6

1.2.3 U.S. PV Installations by Application and Sector ............................................................... 7

1.2.4 U.S. States with the Largest PV Markets ........................................................................... 9

1.3 Global and U.S. Installed CSP Capacity ............................................................................. 10

1.3.1 Cumulative Installed CSP Worldwide ............................................................................. 10

1.3.2 Major non-U.S. International Markets for CSP ............................................................... 10

1.3.3 U.S. Installed CSP Capacity ............................................................................................ 11

1.4 References ........................................................................................................................... 13

2. Industry Trends, Photovoltaic and Concentrating Solar Power ........................................ 15

2.1 PV Production Trends ......................................................................................................... 15

2.1.1 Global PV Production ...................................................................................................... 15

2.1.2 U.S. PV Production .......................................................................................................... 18

2.2 Global and U.S. PV Shipments and Revenue ..................................................................... 20

2.2.1 Global PV Shipments ....................................................................................................... 20

2.2.2 Global PV Cell/Module Revenue .................................................................................... 23

2.2.3 U.S. PV Shipments .......................................................................................................... 24

2.2.4 U.S. PV Cell/Module Revenue ........................................................................................ 26

2.2.5 U.S. PV Imports and Exports ........................................................................................... 27

2.3 CSP Manufacturer and Shipment Trends ........................................................................... 29

2.3.1 CSP Manufacturers .......................................................................................................... 29

2.3.2 CSP Shipments................................................................................................................. 29

2.4 Material and Supply Chain Issues....................................................................................... 30

2.4.1 Polysilicon Supply for PV ............................................................................................... 30

2.4.2 Rare Metals Supply and Demand for PV ......................................................................... 36

2.4.3 Glass Supply for PV ......................................................................................................... 36

2.4.4 Material and Water Constraints for CSP ......................................................................... 37

2.4.5 Land and Transmission Constraints for Utility-Scale Solar ............................................ 38

2.5 Solar Industry Employment Trends .................................................................................... 39

2.5.1 Types of Jobs in the PV and CSP Industries.................................................................... 40

2.5.2 Current and Projected Employment in the Solar Industry, Global and U.S. ................... 41

2.5.3 Labor Intensity in the PV Industry, Global and U.S. ....................................................... 43

2.5.4 Employment and Labor Intensity in the U.S. and Global CSP Industry ......................... 44

ii

2.5.5 Quality Assurance and Certification for Solar PV Installation ........................................ 45

2.5.6 DOE Response to Current Barriers in Workforce Development ..................................... 45

2.6 References ........................................................................................................................... 46

3. Cost, Price, and Performance Trends ................................................................................... 50

3.1. Levelized Cost of Energy, PV and CSP............................................................................. 50

3.2. Solar Resource and Capacity Factor, PV and CSP ............................................................ 51

3.2.1. Solar Resource for PV .................................................................................................... 51

3.2.2 Solar Resource for CSP ................................................................................................... 53

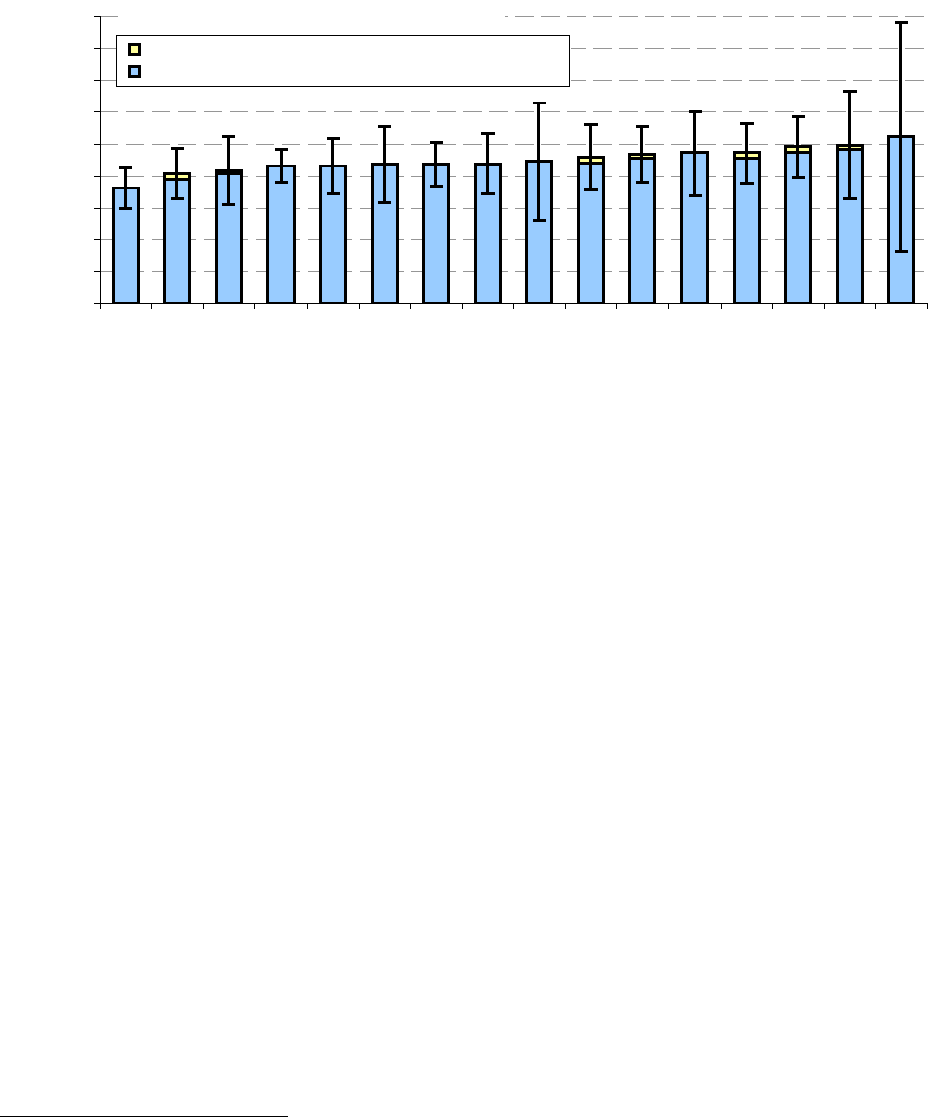

3.2.3 Capacity Factor, PV and CSP .......................................................................................... 54

3.3 PV Cell, Module, and System Efficiency ........................................................................... 55

3.3.1 PV Cell Type and Efficiency ........................................................................................... 56

3.3.2 PV Module Efficiency ..................................................................................................... 57

3.3.3 PV System Efficiency and Derate Factor ........................................................................ 58

3.4 PV Module Reliability ........................................................................................................ 58

3.5 PV Module Price Trends ..................................................................................................... 59

3.6 PV Installation Cost Trends ................................................................................................ 61

3.7 PV Operations and Maintenance ........................................................................................ 69

3.7.1 PV Operations and Maintenance Not Including Inverter Replacement ........................... 69

3.7.2 PV Inverter Replacement and Warranty Trends .............................................................. 72

3.8 CSP Installation and Operations and Maintenance Cost Trends ........................................ 73

3.9 CSP Technology Characteristics and System Performance................................................ 73

3.9.1 Parabolic Trough Technology .......................................................................................... 73

3.9.2 Power Tower Technology ................................................................................................ 74

3.9.3 Dish-Engine Technology ................................................................................................. 74

3.9.4 Linear Fresnel Reflector Technology .............................................................................. 74

3.9.5 Storage ............................................................................................................................. 74

3.9.6 Heat-Transfer Fluid .......................................................................................................... 74

3.9.7 Water Use ......................................................................................................................... 75

3.9.8 Land Requirements .......................................................................................................... 75

3.10 References ......................................................................................................................... 75

4. Policy and Other Market Drivers .......................................................................................... 78

4.1. Federal Policies and Incentives, PV and CSP .................................................................... 78

4.1.1 Investment Tax Credit...................................................................................................... 78

4.1.2 Renewable Energy Grants ................................................................................................ 79

4.1.3 Manufacturing Tax Credit ................................................................................................ 80

4.1.4 MACRS and Bonus Depreciation .................................................................................... 80

4.1.5 Renewable Energy Loan Guarantee Program .................................................................. 80

4.1.6 Clean Renewable Energy Bonds ...................................................................................... 82

4.1.7 Solar on Federal Property ................................................................................................ 83

4.1.8 State Energy Program ...................................................................................................... 83

4.1.9 Energy Efficiency and Conservation Block Grant Program ............................................ 84

4.1.10 Renewable Energy Production Incentive ....................................................................... 84

4.1.11 Additional Resources ..................................................................................................... 84

4.2 State and Local Policies, Incentives, and Rules and Regulations ....................................... 85

4.2.1 Planning and Permitting ................................................................................................... 85

4.2.2 Interconnection ................................................................................................................ 86

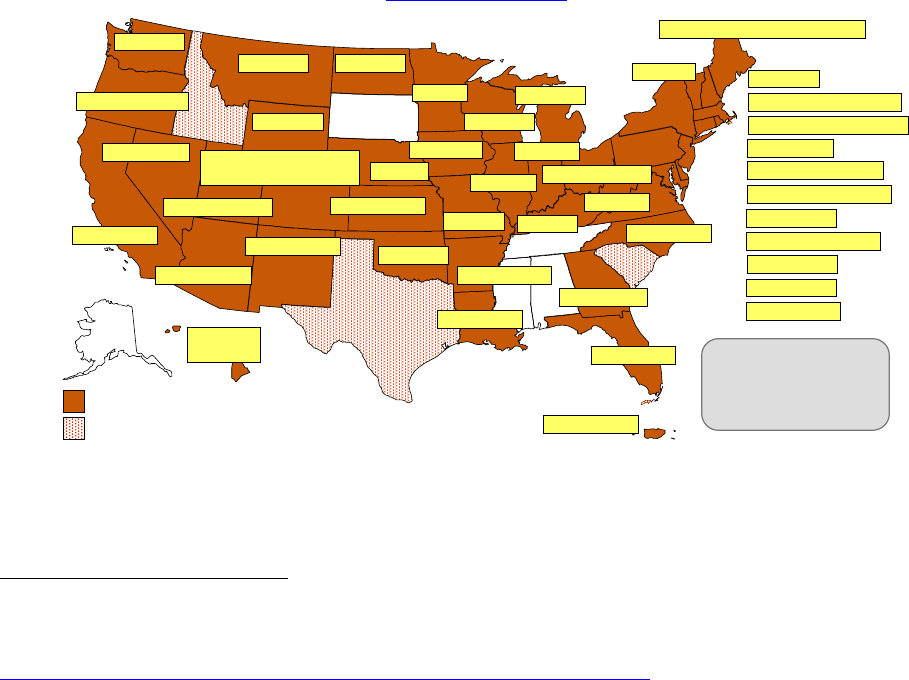

4.2.3 Net Metering .................................................................................................................... 89

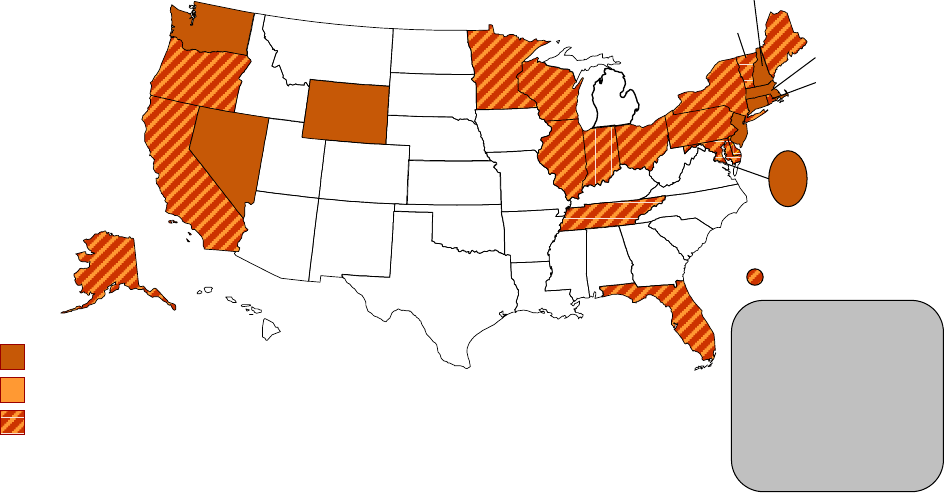

4.2.4 Direct Cash Incentive Programs ...................................................................................... 90

iii

4.2.5 Renewable Portfolio Standards and Solar Set-Asides ..................................................... 91

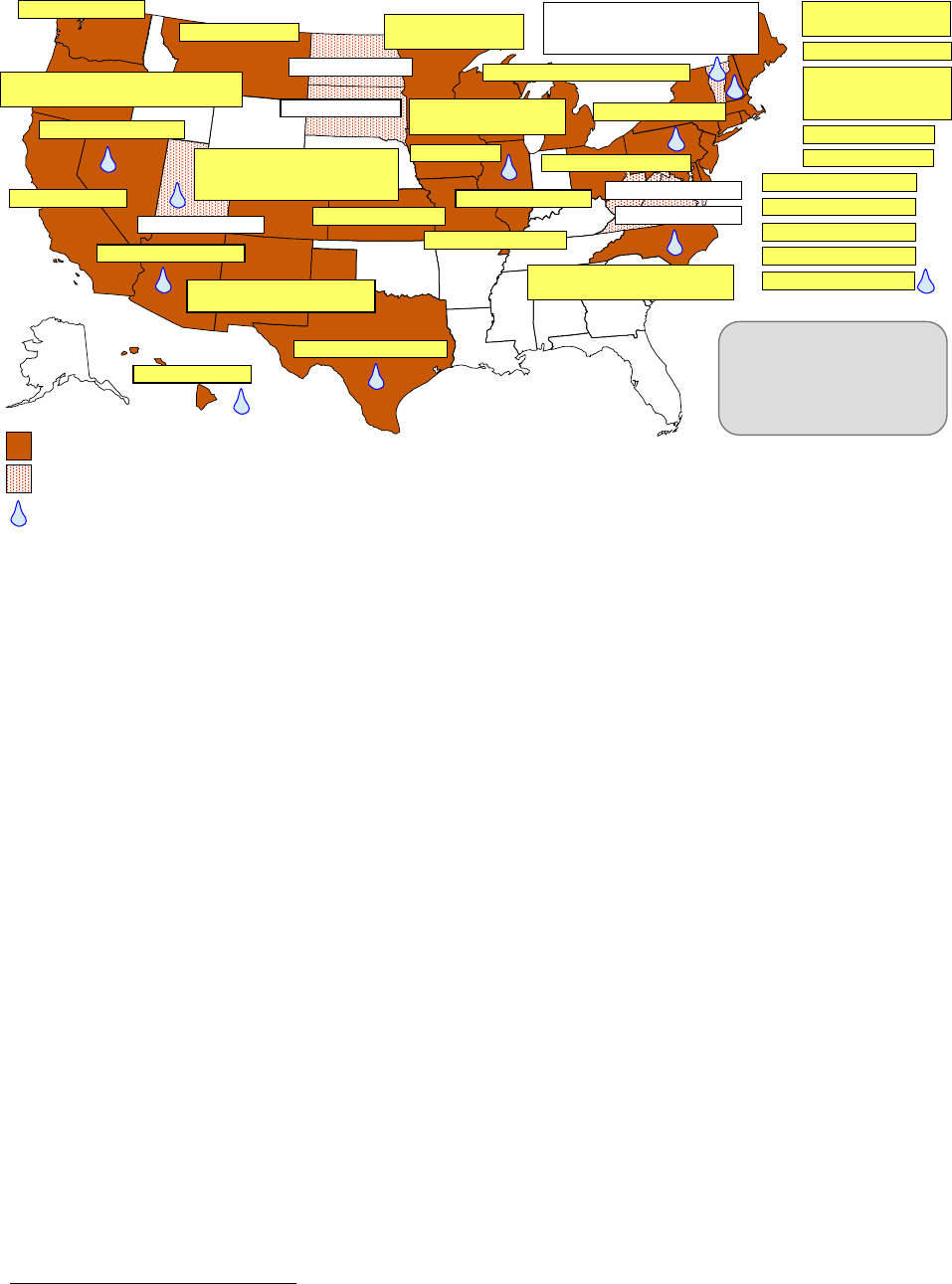

4.2.6 Clean Energy Funds ......................................................................................................... 94

4.2.7 Emerging Trends .............................................................................................................. 95

4.3 Private Sector and Market-Based Developments to Facilitate Solar Deployment ............. 96

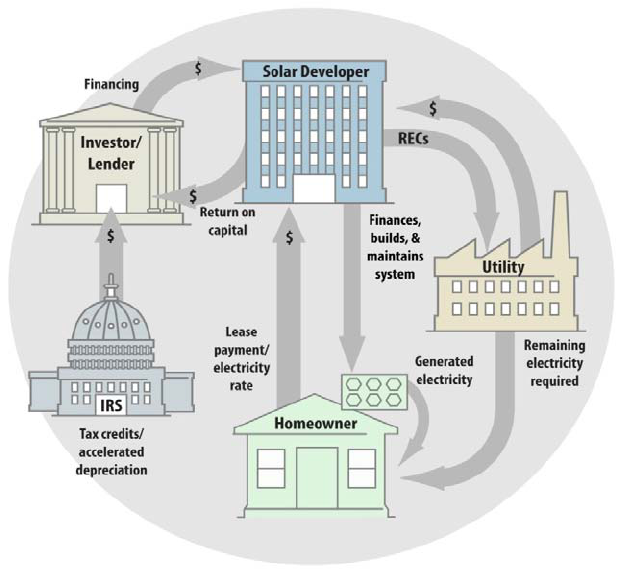

4.3.1 Third-Party Power Purchase Agreement Financing ........................................................ 96

4.3.2 Customer Solar Lease Financing ..................................................................................... 98

4.3.3 Property-Assessed Clean Energy Programs ..................................................................... 99

4.3.4 Alternative Financing Structures: Partnership Flips and Leases .................................. 100

4.3.5 Increasing Utility Ownership of Solar Projects ............................................................. 101

4.4 References ......................................................................................................................... 101

5. Investments and Future Outlook ......................................................................................... 105

5.1 Private Investment in Solar Energy .................................................................................. 105

5.2 U.S. Department of Energy Investment in Solar Energy .................................................. 109

5.3 Solar Market Forecasts, PV and CSP ............................................................................... 112

5.3.1 PV Market Forecasts ...................................................................................................... 112

5.3.2 CSP Market Forecasts .................................................................................................... 116

5.4 References ......................................................................................................................... 117

Figures

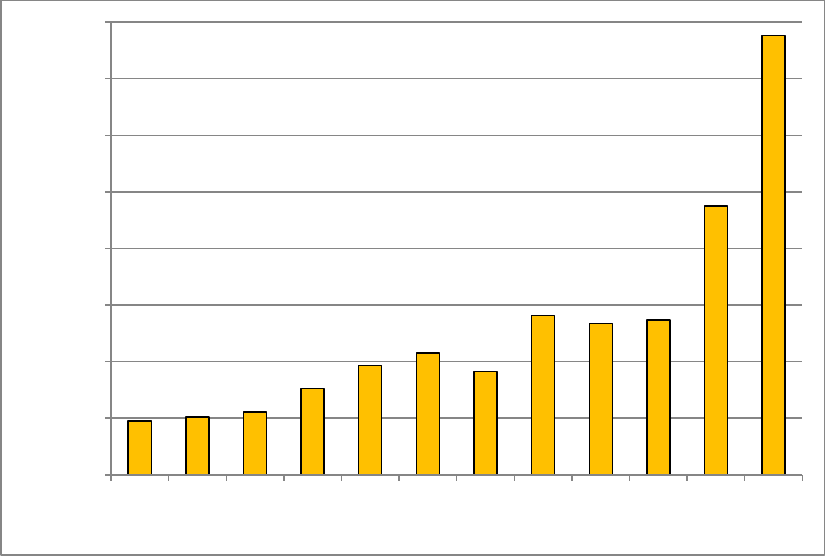

Figure 1.1 Global cumulative installed PV capacity through 2008 ................................................ 1

Figure 1.2 Cumulative installed PV capacity in top seven countries ............................................. 2

Figure 1.3. Annual installed PV capacity in top seven countries ................................................... 3

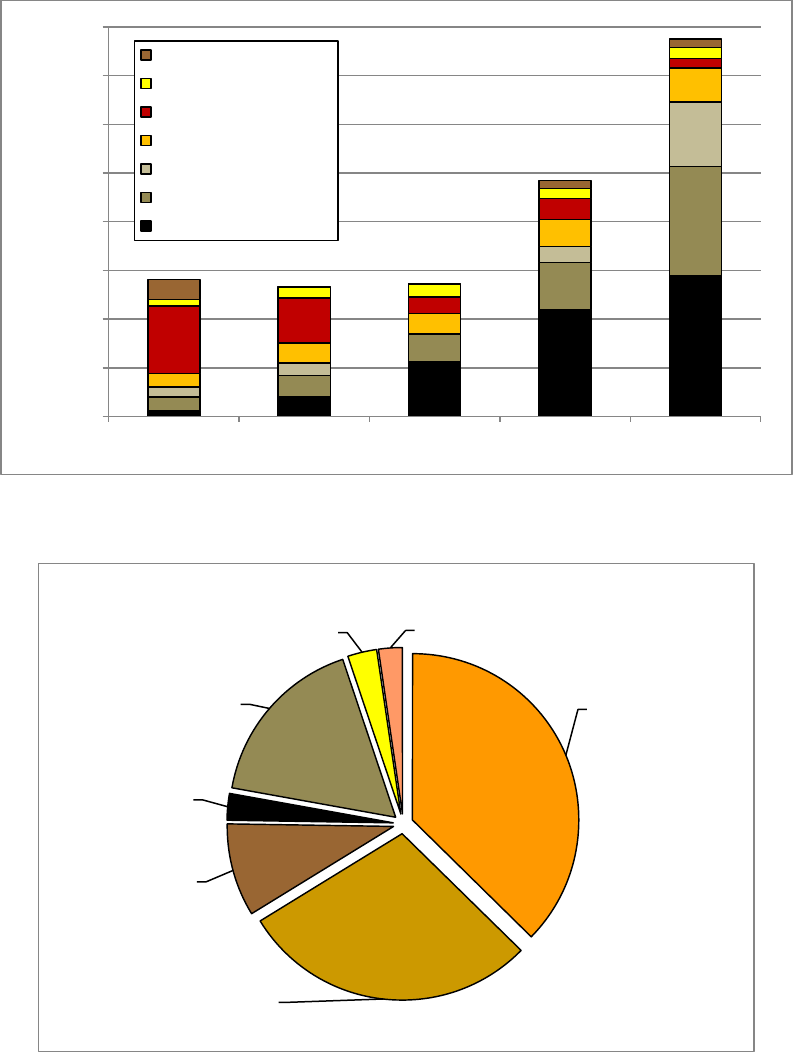

Figure 1.4. Global cumulative installed PV capacity by interconnection status ............................ 4

Figure 1.5. Application market share of cumulative installed PV capacity in IEA countries

through 2008 ........................................................................................................................... 5

Figure 1.6. U.S. cumulative installed PV capacity by interconnection status ................................ 7

Figure 1.7. U.S. PV applications, 2008 market shares ................................................................... 7

Figure 1.8. Annual trend in number of U.S. grid-connected PV installations by sector ................ 8

Figure 1.9. U.S. annual grid-connected PV capacity ...................................................................... 9

Figure 1.10. Annual grid-connected PV capacity and cumulative market share in top U.S. state

markets, 2004–2008 ................................................................................................................ 9

Figure 1.11. Concentrating solar power plants of the southwest United States ........................... 12

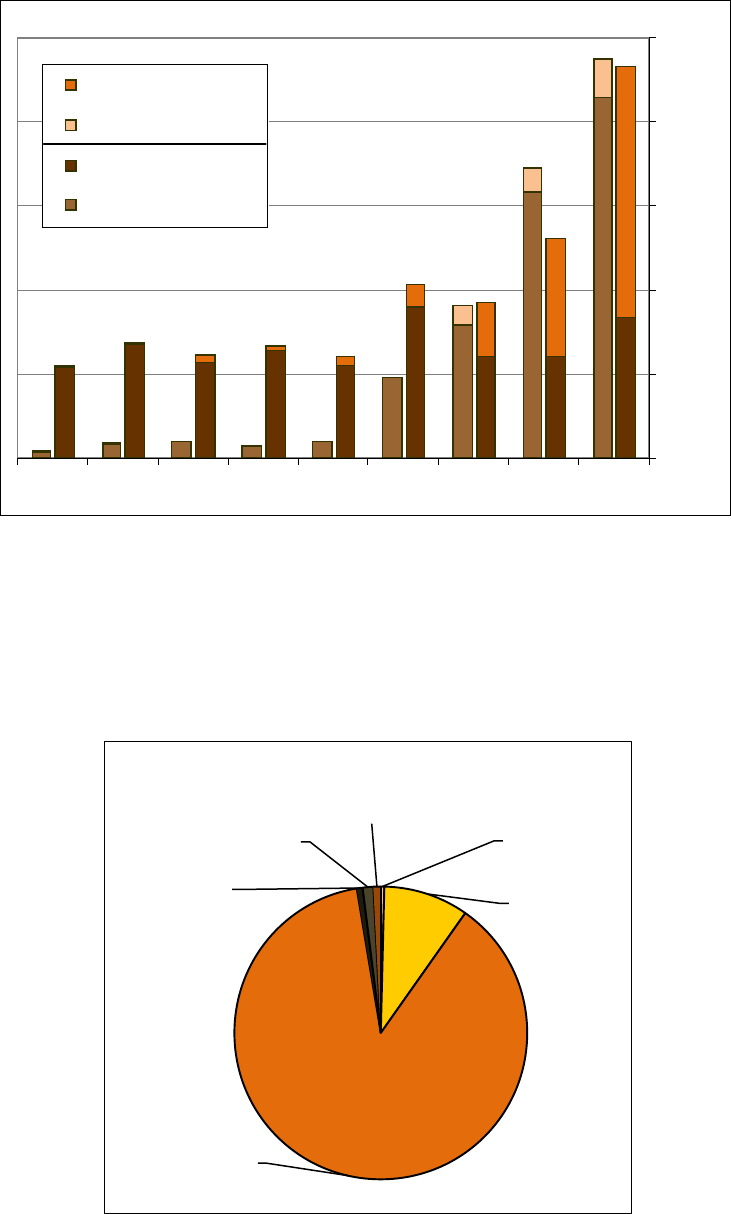

Figure 2.1. Global annual PV cell/module production by region ................................................. 15

Figure 2.2. Top global PV cell/module producers 2008 ............................................................... 16

Figure 2.3. Global annual PV cell/module production by manufacturer 2002–2008 ................... 17

Figure 2.4. U.S. annual PV cell/module production ..................................................................... 18

Figure 2.5. U.S. annual PV cell/module production by U.S. manufacturer .................................. 19

Figure 2.6. Top U.S. PV cell/module producers 2008 .................................................................. 19

Figure 2.7. Global annual PV cell/module shipments by region .................................................. 21

Figure 2.8. Global annual PV cell/module shipments by manufacturer 2004–2008 .................... 22

Figure 2.9. Top global companies for PV cell/module shipments 2008 ....................................... 22

Figure 2.10. Top global companies for PV cell/module revenues 2008 ....................................... 23

Figure 2.11. Global annual PV cell/module shipments by PV technology 1997–2008 ............... 24

Figure 2.12. U.S. annual PV cell/module shipments 1997–2008 ................................................. 25

Figure 2.13. U.S. annual PV cell/module shipments by manufacturer 2004–2008 ...................... 26

Figure 2.14. Top U.S. companies for PV cell/module shipments 2008 ........................................ 26

Figure 2.15. Top U.S. companies for PV cell/module revenues 2008 .......................................... 27

iv

Figure 2.16. U.S. PV cell/module shipments, exports and imports .............................................. 28

Figure 2.17. U.S. exports of PV cells and modules, 2007 destination .......................................... 28

Figure 2.18. Proportion of 2008 polysilicon production categorized by producer ....................... 32

Figure 2.19. Proportion of 2008 polysilicon production categorized by producing country ........ 32

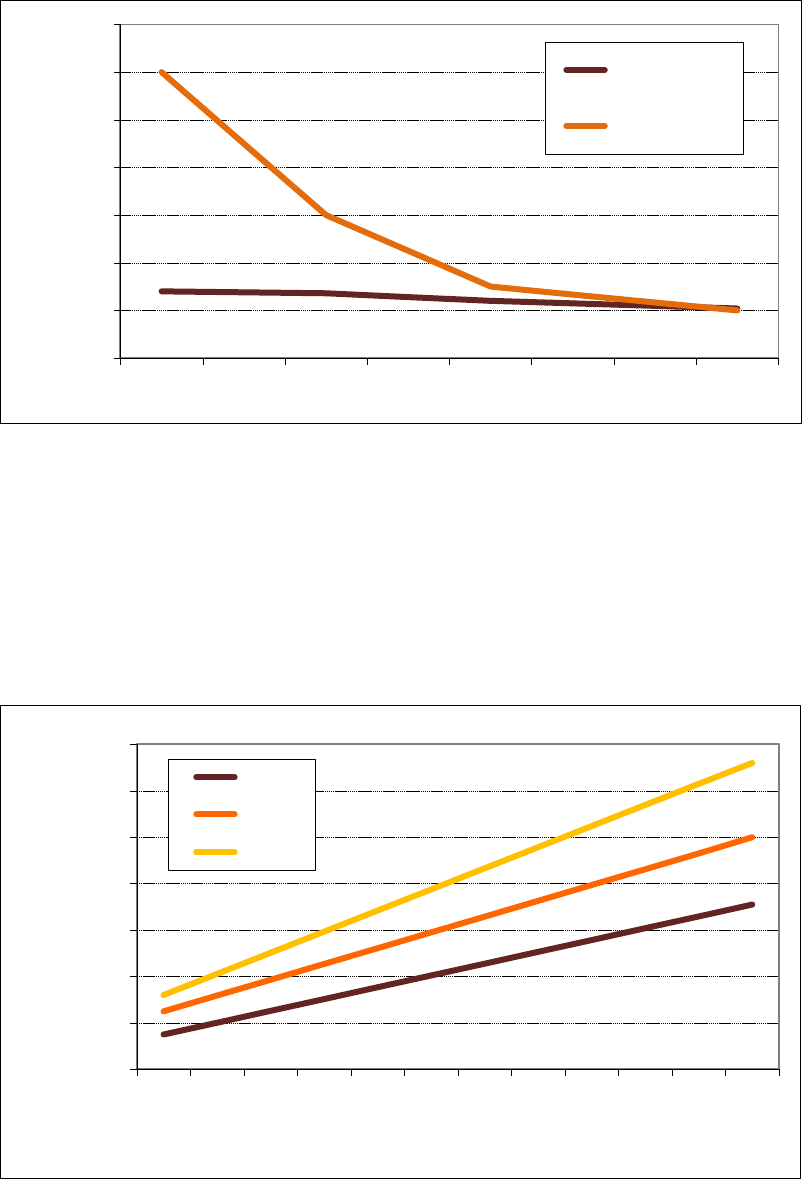

Figure 2.20. Polysilicon supply projections through 2012 ........................................................... 33

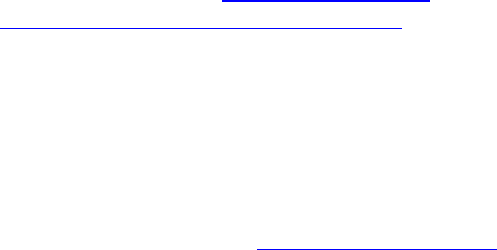

Figure 2.21. Polysilicon price projections through 2015 .............................................................. 35

Figure 2.22. PV module sensitivity to polysilicon price and utilization ....................................... 35

Figure 3.1. LCOE for residential PV systems in several U.S. cities in 2008, with and without the

federal investment tax credit ................................................................................................. 51

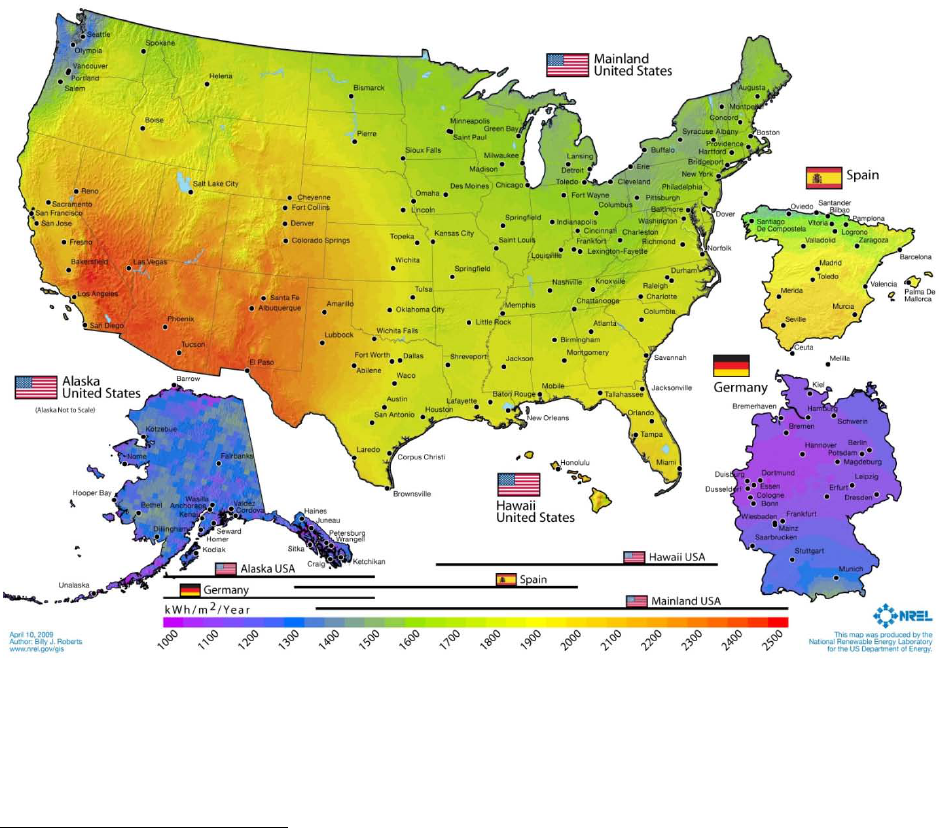

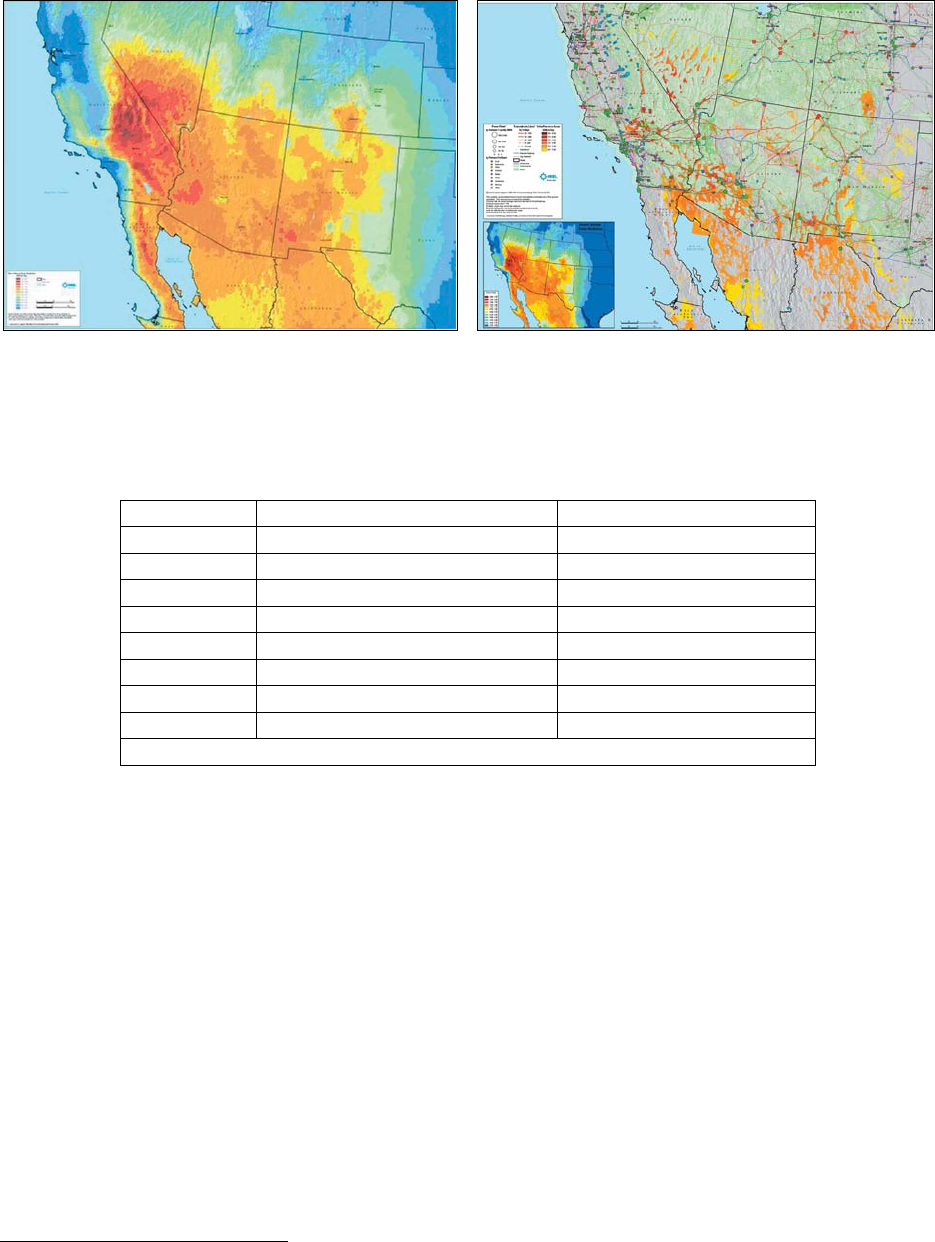

Figure 3.2 Photovoltaic solar resource for the United States, Spain, and Germany ..................... 52

Figure 3.3. Direct-normal solar resource in the U.S. Southwest .................................................. 54

Figure 3.4. Direct-normal solar radiation in the U.S. Southwest, filtered by resource, land use,

and topography...................................................................................................................... 54

Figure 3.5. PV capacity factors varying by insolation and use of tracking systems ..................... 55

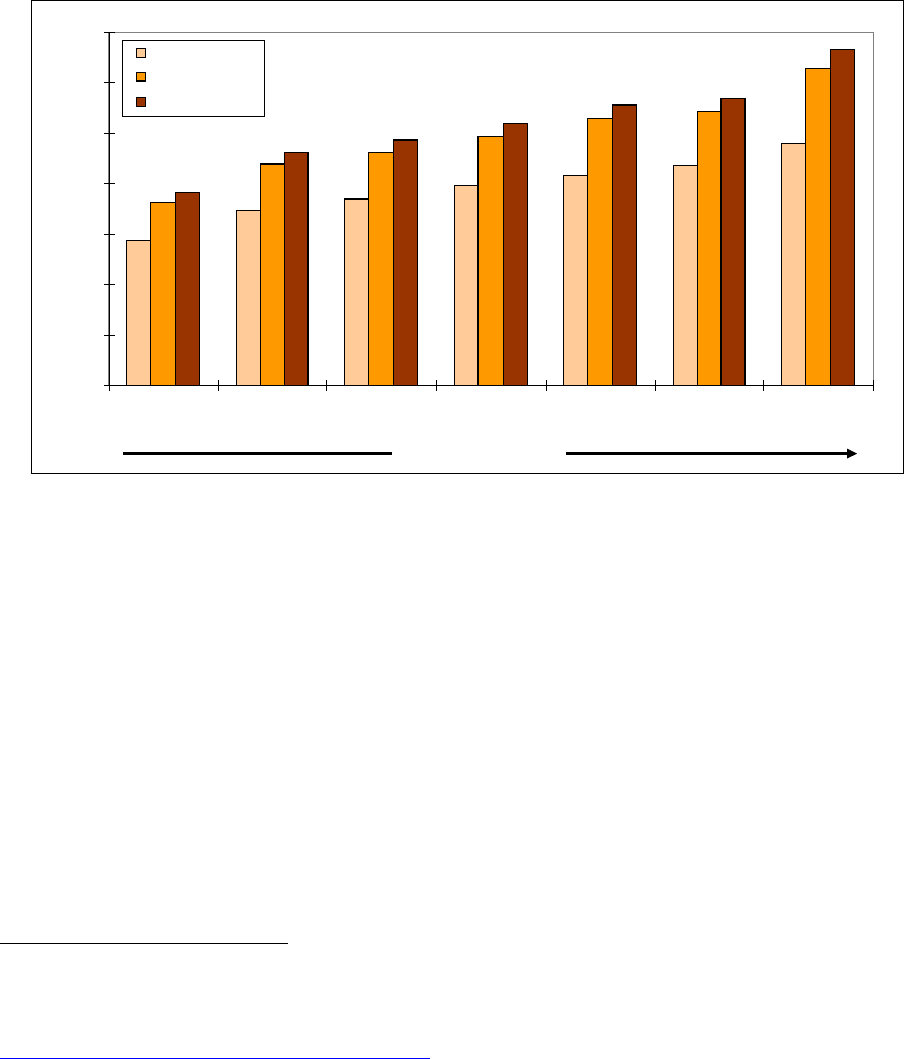

Figure 3.6. Best research cell efficiencies 1975–2009 ................................................................. 57

Figure 3.7. Best-in-class commercial module efficiencies, 1999–2008, compiled from module

survey data ............................................................................................................................ 58

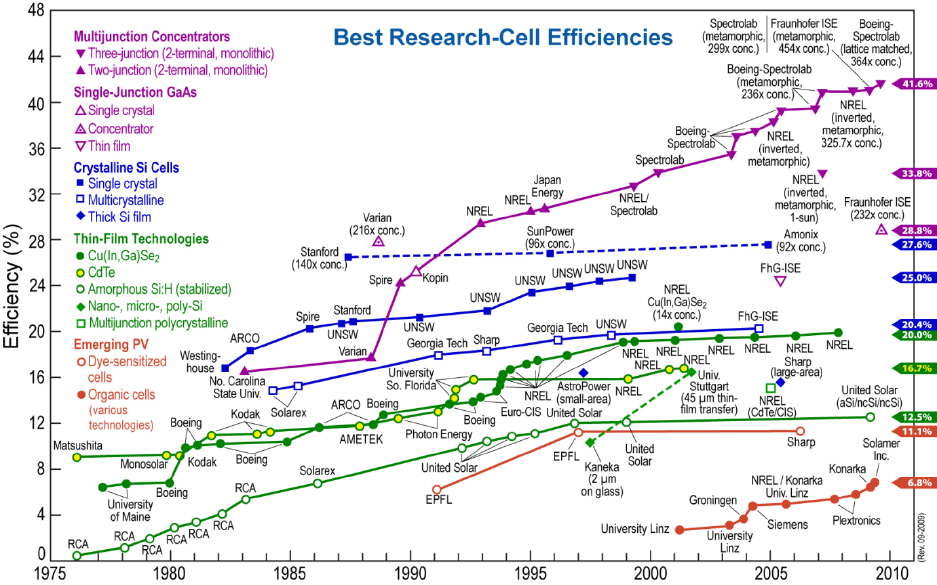

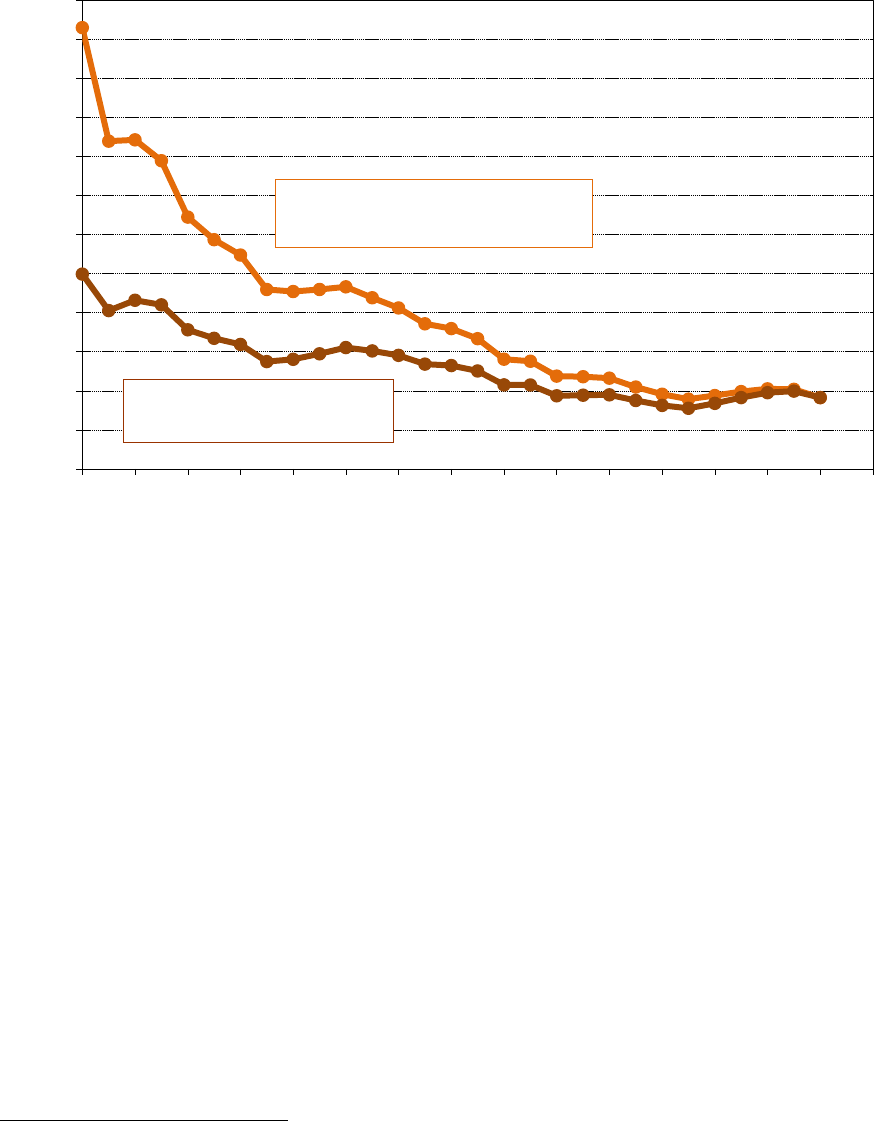

Figure 3.8. Global, average PV module prices, all PV technologies, 1980–2008 ........................ 60

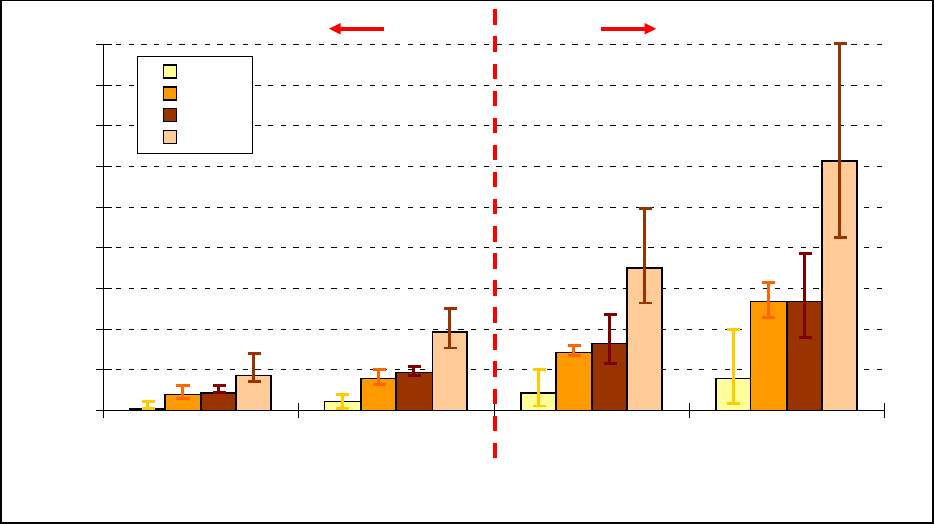

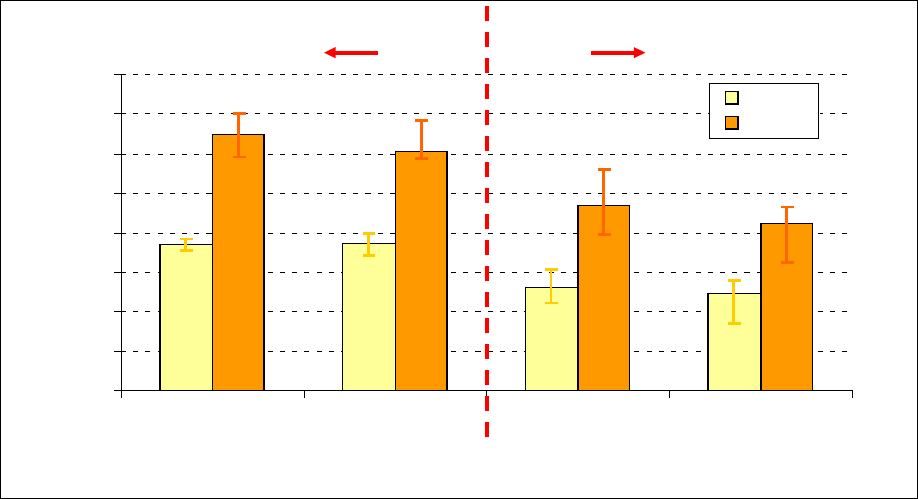

Figure 3.9. Installed cost trends over time .................................................................................... 62

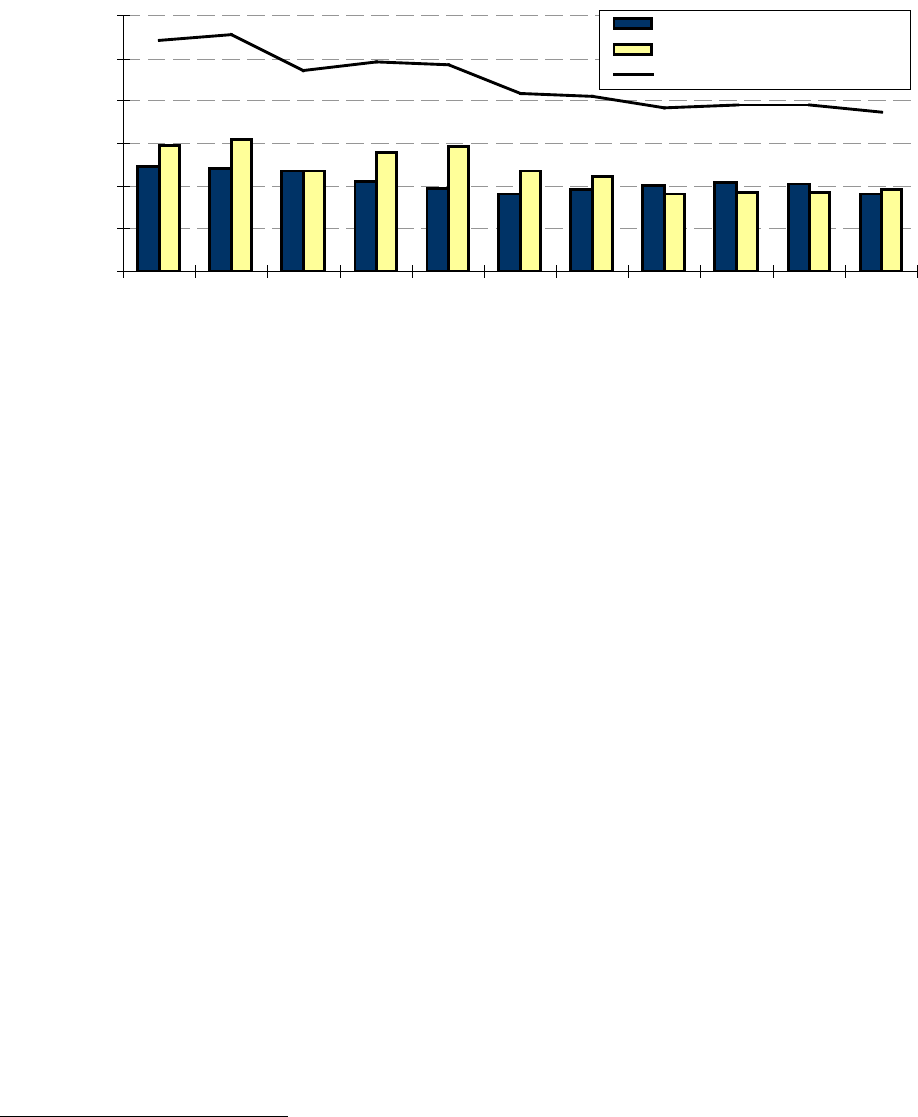

Figure 3.10. Module and non-module cost trends over time ........................................................ 63

Figure 3.11. Average installed cost of residential systems completed in 2007 in Japan, Germany,

and the United States ............................................................................................................ 64

Figure 3.12. Variation in installed costs among U.S. states ......................................................... 65

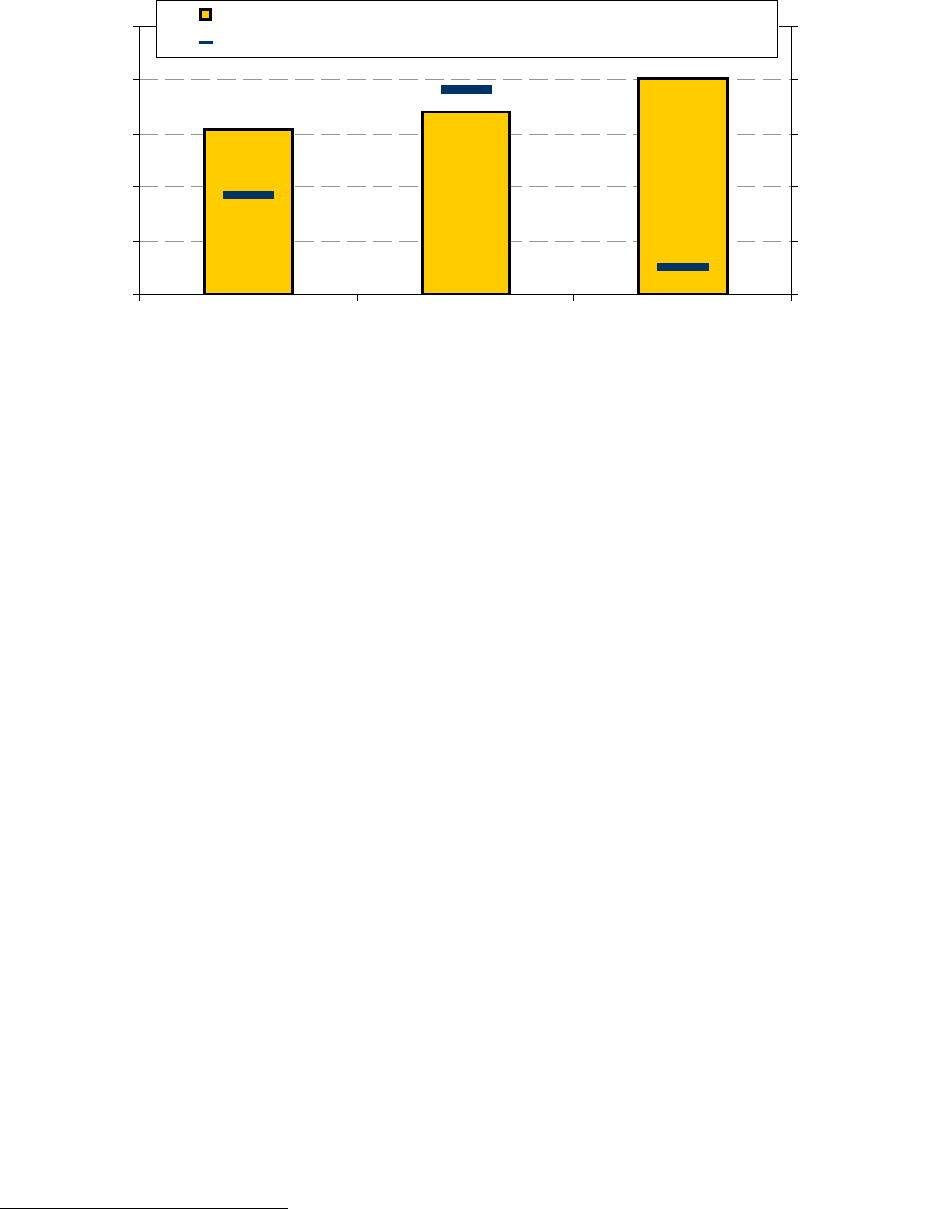

Figure 3.13. PV system size trends over time ............................................................................... 66

Figure 3.14. Variation in installed cost according to PV system size ........................................... 66

Figure 3.15. Comparison of installed cost for residential retrofit vs. new construction ............... 67

Figure 3.16. Comparison of installed cost for crystalline vs. thin-film systems .......................... 67

Figure 3.17. Module, inverter, and other costs ............................................................................. 68

Figure 3.18. PV installer data on component costs ....................................................................... 69

Figure 3.19. Inverter default warranties, 2002–2008 .................................................................... 72

Figure 3.20. Generic parabolic trough CSP cost breakdown ........................................................ 73

Figure 4.1. Distribution of round 1 and 2 CREB allocation, percent of projects by technology.. 83

Figure 4.2. Distribution of round 3 CREB allocation, percent of projects by technology ........... 83

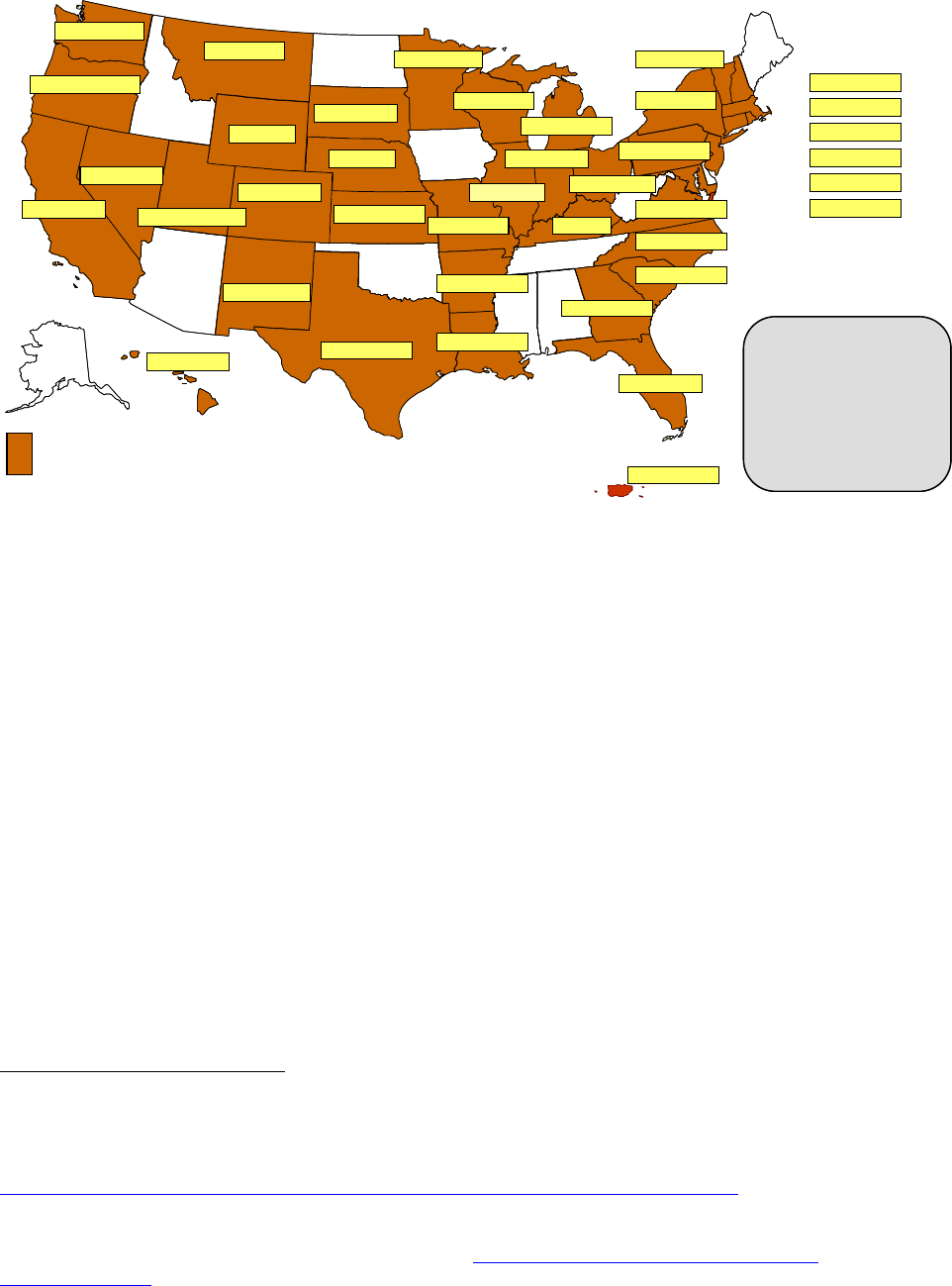

Figure 4.3. Interconnection Standards, November 2009 .............................................................. 88

Figure 4.4. Net Metering Policies, October 2009 ......................................................................... 89

Figure 4.5. States that offer direct cash incentives for solar projects, September 2009 ............... 91

Figure 4.6. State renewable portfolio standards and goals, October 2009 ................................... 92

Figure 4.7. Solar capacity to meet existing RPS solar set-aside requirements, November 2009 . 93

Figure 4.8. Estimated system benefit funds for renewables, May 2009 ....................................... 94

Figure 4.9. The residential power purchase agreement ................................................................ 97

Figure 4.10. Property-assessed clean energy programs, November 2009 .................................. 100

Figure 5.1. Global capital investments in solar energy ............................................................... 106

Figure 5.2. U.S. capital investments in solar energy .................................................................. 107

Figure 5.3. Global venture capital and private-equity investments by solar technology ............ 108

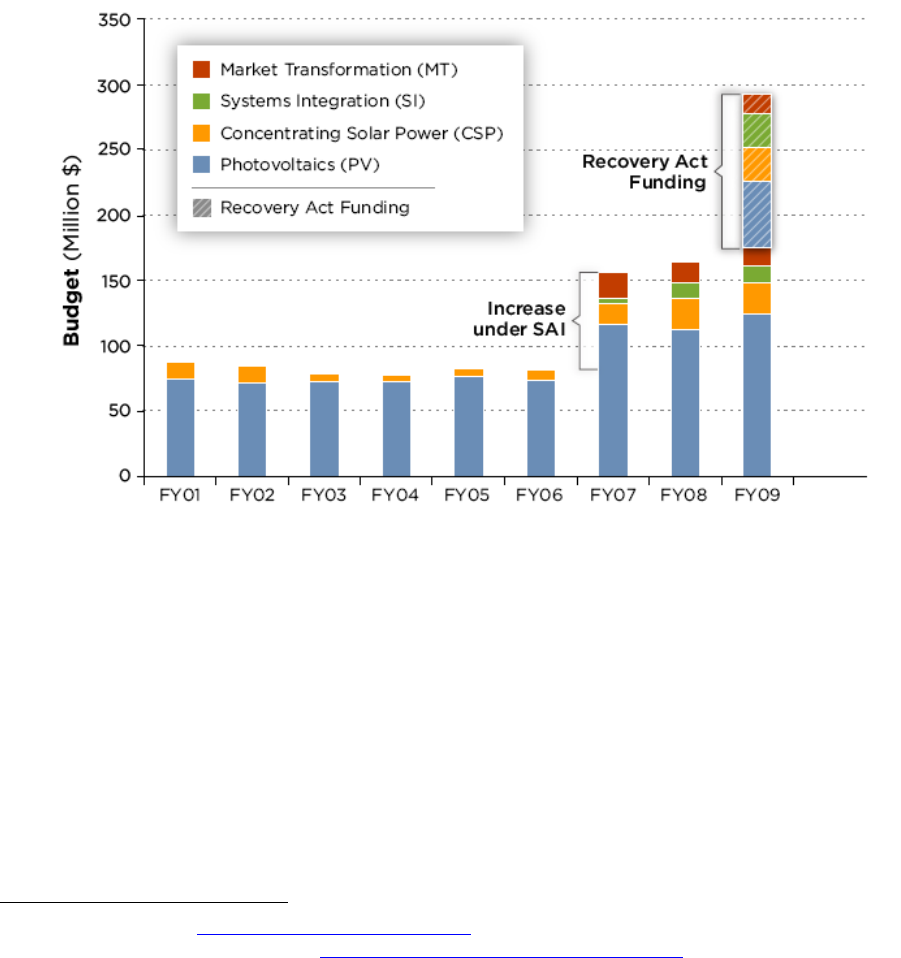

Figure 5.4. DOE SETP budget history from FY 2001 to FY 2009 ............................................ 109

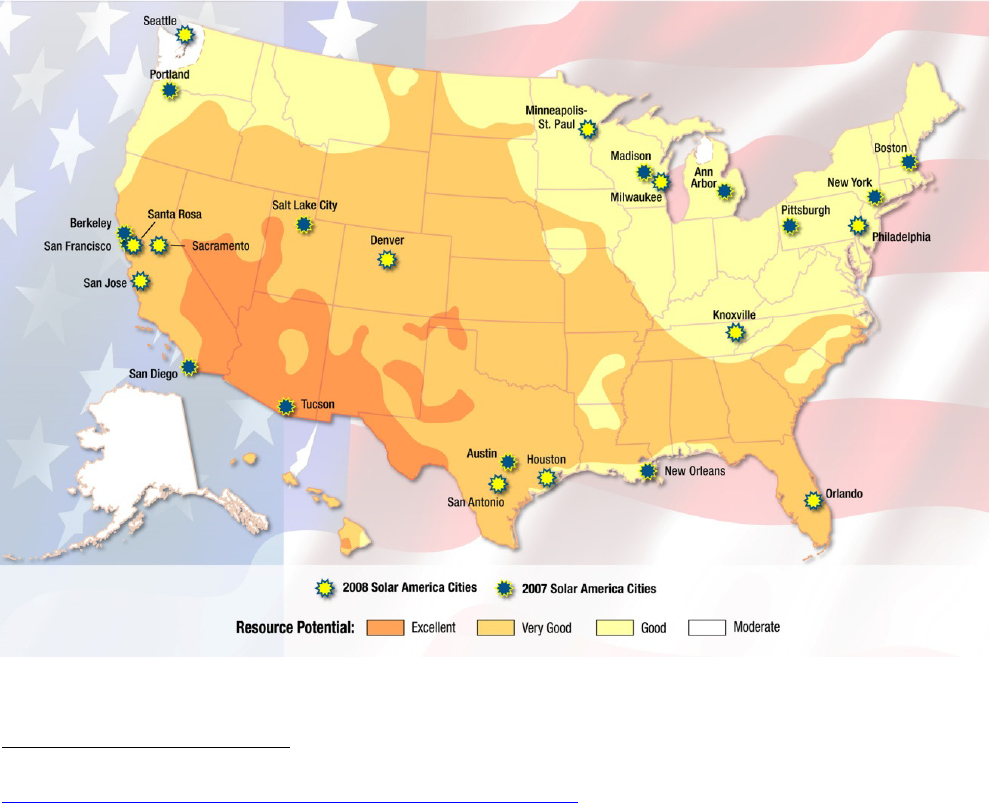

Figure 5.5. 2007 and 2008 Solar America Cities ........................................................................ 111

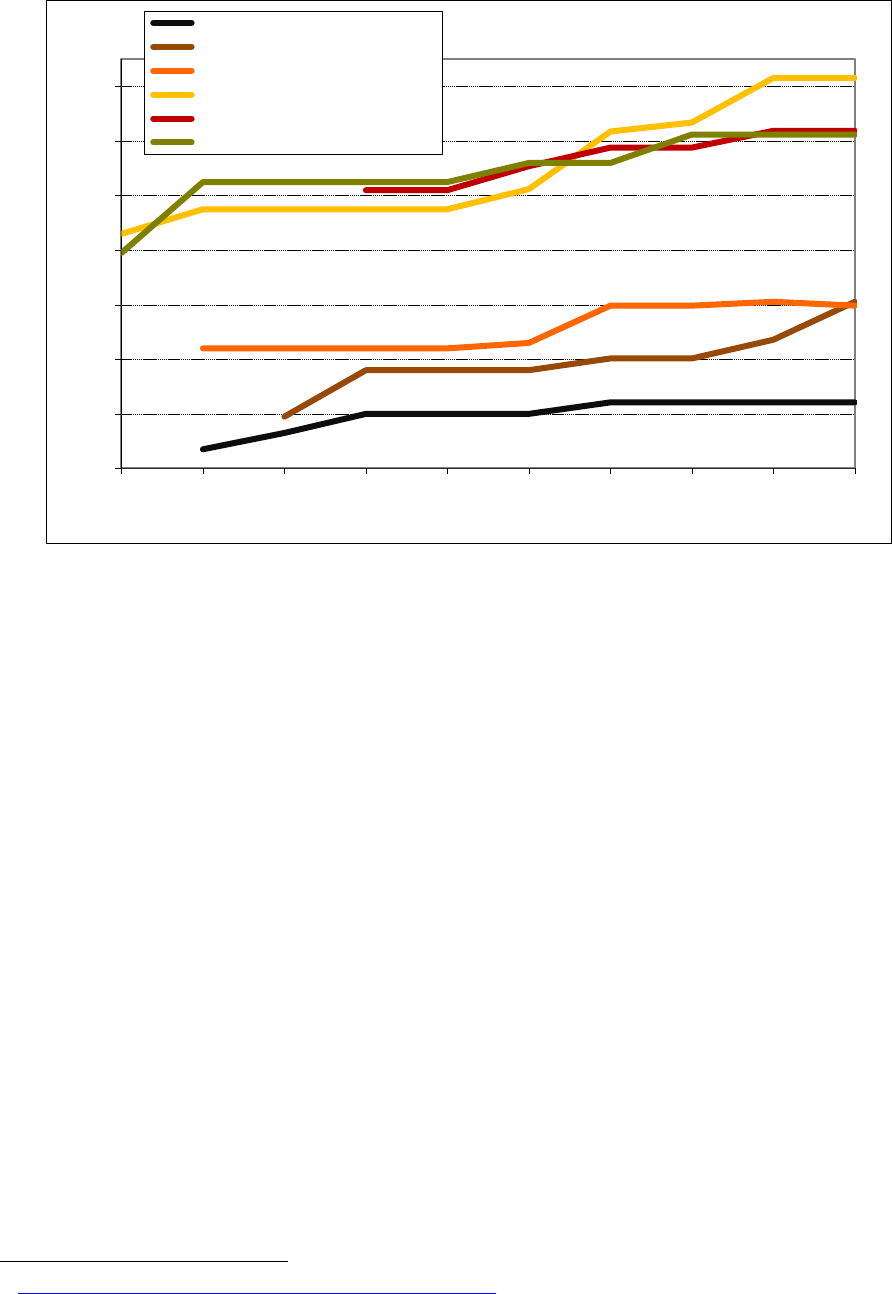

Figure 5.6. Global total PV module production forecasts .......................................................... 113

Figure 5.7. Global thin-film PV module production forecasts ................................................... 114

v

Figure 5.8. Global PV module demand forecasts ....................................................................... 115

Figure 5.9. Global PV module and system price forecasts ......................................................... 116

Tables

Table 1.1. Global Installed CSP Plants ......................................................................................... 10

Table 1.2. CSP Plants Under Construction, by Country ............................................................... 11

Table 1.3. Installed CSP Plants in the United States .................................................................... 12

Table 2.1. CSP Component Manufacturers .................................................................................. 29

Table 2.2. Annual U.S. Shipments: Parabolic Dish and Trough, 1998–2007 .............................. 29

Table 2.3. Global PV Labor Intensity in 2008 (Direct and Indirect Jobs) .................................... 43

Table 3.1. Ideal CSP Land Area and Resource Potential in Seven Southwestern States ............. 54

Table 3.2. Module Price, Manufacturing Cost, and Efficiency Estimates by Technology, 2008 . 61

Table 3.3. Summary of Arizona PV System O&M Studies, Not Including O&M Related to

Inverter Replacement/Rebuilding ......................................................................................... 71

Table 4.1. DOE Loan Guarantee Programs .................................................................................. 81

Table 5.1. Global CSP Planned Projects, Capacity by Country, Through 2015 ........................ 117

Table 5.2. Global CSP Planned Projects, Market Share by Country, Through 2015 ................. 117

Table 5.3. U.S. CSP Power Purchase Agreement Pipeline, Market Share by Technology,

Through 2015 ...................................................................................................................... 117

vi

Acknowledgments

Primary Authors: Selya Price (NREL) and Robert Margolis (NREL).

Contributing Authors: Galen Barbose (LBNL), John Bartlett (New West Technologies),

Karlynn Cory (NREL), Toby Couture, Jennifer DeCesaro (Sentech, Inc), Paul Denholm (NREL),

Easan Drury (NREL), Mark Frickel (Sentech, Inc), Charles Hemmeline (DOE SETP), Ted James

(NREL), Michael Mendelsohn (NREL), Sean Ong (NREL), Alexander Pak (MIT), Lauren Poole,

Carla Peterman (LBNL), Paul Schwabe (NREL), Arun Soni (Sentech, Inc), Bethany Speer

(NREL), Ryan Wiser (LBNL), and Jarett Zuboy.

For providing information, consultation, advice, and feedback, the authors thank: Doug

Arent (NREL), Bill Babiuch (Midwest Research Institute), Justin Baca (SEIA), Lynn Billman

(NREL), Katie Bolcar (DOE SETP), Austin Brown (DOE EERE), Christopher Cameron (SNL),

Barry Friedman (NREL), Rachel Gelman (NREL), Tom Kimbis (The Solar Foundation), Claire

Kreycik (NREL), Mark Lausten (Sentech, Inc), Jim Leyshon (NREL), Stephen Lommele

(NREL), John Lushetsky (DOE SETP), Kevin Lynn (DOE SETP), Marie Mapes (DOE SETP),

Jeff Mazer (U.S. Department of Commerce, National Institute of Standards and Technology),

Lynn McLarty (Technology & Management Services, Inc.), Jim McVeigh (Sentech, Inc), JoAnn

Milliken (DOE EERE), Hannah Muller (DOE SETP), Judy Oberg (NREL), Jay Paidipati

(Navigant Consulting), Christie Poimbeauf (Technology & Management Services, Inc.), Billy

Roberts (NREL), David Rodgers (DOE EERE), Thomas Schneider (NREL), Scott Stephens

(DOE SETP), Frank “Tex” Wilkins (DOE SETP), Peter Wong (DOE EIA), as well as Meredith

Annex, Leonardo Banchik, Victor Kane, and Jonathan Cronin-Kanevsky, who contributed to the

report during their internships at DOE SETP.

Reviewers included: Bill Babiuch (Midwest Research Institute), Lynn Billman (NREL), Charles

Hemmeline (DOE SETP), Ted James (NREL), John Lushetsky (DOE SETP), Marie Mapes

(DOE SETP), JoAnn Milliken (DOE EERE), Scott Stephens (DOE SETP), and Frank “Tex”

Wilkins (DOE SETP).

For comprehensive editing and publication support, we are grateful to: Michelle Kubik

(NREL) and Susan Moon (NREL), as well as Jarett Zuboy, and Erik Ness (NREL); and to Stacy

Buchanan (NREL) for her cover design.

For the use of and support with their data, special thanks to: Paula Mints (Photovoltaic

Service Program, Navigant Consulting), Larry Sherwood (Sherwood Associates), Nathaniel

Bullard (New Energy Finance), and Travis Bradford (Prometheus Institute).

For support of this project, the authors thank: The U.S. DOE Solar Energy Technologies

Program (SETP) and the U.S. DOE Office of Energy Efficiency and Renewable Energy (EERE).

NREL’s contributions to this report were funded by the Solar Energy Technologies Program,

Office of Energy Efficiency and Renewable Energy of the U.S. Department of Energy under

Contract No. DE-AC36-08-GO28308. The authors are solely responsible for any omissions or

errors contained herein.

vii

List of Acronyms

a-Si amorphous silicon

AC alternating current

AMT alternative minimum tax

APS Arizona Public Service

ARRA American Recovery and Reinvestment and Act of 2009 (S.1, “Stimulus Bill”)

ASES American Solar Energy Society

BIPV building-integrated photovoltaics

BLM U.S. Bureau of Land Management

BNL Brookhaven National Laboratory

CAGR compound annual growth rate

CdTe cadmium telluride

CEC California Energy Commission

CIGS copper indium gallium (di)selenide

CIS copper indium (di)selenide

CPV concentrating photovoltaics

CREB clean renewable energy bond

CSI California Solar Initiative

CSP concentrating solar power

DC direct current

DG distributed generation

DOE U.S. Department of Energy

DOI U.S. Department of the Interior

DSIRE Database of State Incentives for Renewables & Efficiency

EEGBC Energy Efficiency and Conservation Block Grants

EERE U.S. DOE’s Office of Energy Efficiency and Renewable Energy

EESA Emergency Economic Stabilization Act of 2008 (H.R. 1424, “Bailout Bill”)

EIA U.S. DOE’s Energy Information Administration

EPA U.S. Environmental Protection Agency

EPACT Energy Policy Act

EU European Union

FBR fluidized bed reactor

FERC Federal Energy Regulatory Commission

FIT feed-in tariff

FTE full-time equivalent

FY fiscal year

GW gigawatt

GWh gigawatt-hour

HTF heat-transfer fluid

IEEE Institute of Electrical and Electronics Engineers

IREC Interstate Renewable Energy Council

IRS Internal Revenue Service

ISCC integrated solar combined cycle

ISEGS Ivanpah Solar Electric Generating System

ITC investment tax credit (federal)

kW kilowatt

kWh kilowatt-hour

viii

LBNL Lawrence Berkeley National Laboratory

LCD liquid crystal display

LCOE levelized cost of energy

LSE load-serving entity

M&A mergers and acquisitions

MACRS Modified Accelerated Cost Recovery System (federal)

MENA Middle East and North Africa

MG-Si metallurgical-grade silicon

MOU memorandum of understanding

MT metric ton

MW megawatt

MWh megawatt-hour

NABCEP North American Board of Certified Energy Practitioners

NREL National Renewable Energy Laboratory

NYSERDA New York State Energy Research and Development Authority

O&M operations and maintenance

ORNL Oak Ridge National Laboratory

PACE property-assessed clean energy

PE private equity

PEIS Programmatic Environmental Impact Statement

PPA power purchase agreement

PV photovoltaics

R&D research and development

REC renewable energy certificate

REPI Renewable Energy Production Incentive (federal)

RETI Renewable Energy Transmission Initiative

ROW rest of the world

RPS renewable portfolio standard

SAI Solar America Initiative

SBC system benefits charge

SEGS Solar Electricity Generating Stations

SEIA Solar Energy Industries Association

SEP State Energy Program

SEPA Solar Electric Power Association

SETP U.S. DOE’s Solar Energy Technologies Program

SGIP Small Generator Interconnection Procedure

SNL Sandia National Laboratories

SREC Solar Renewable Energy Certificate

TEP Tucson Electric Power

TES thermal energy storage

TW terawatt

UEDS utility external disconnect switch

UMG-Si upgraded metallurgical-grade silicon

UNEP United Nations Environment Programme

VC venture capital

W watt

WGA Western Governors’ Association

WREZ Western Renewable Energy Zones

ix

Executive Summary

The focus of this report is the U.S. solar electricity market, including photovoltaic (PV) and

concentrating solar power (CSP) technologies. The report is organized into five chapters.

Chapter 1 provides an overview of global and U.S. installation trends. Chapter 2 presents

production and shipment data, material and supply chain issues, and solar industry employment

trends. Chapter 3 presents cost, price, and performance trends. Chapter 4 discusses policy and

market drivers such as recently passed federal legislation, state and local policies, and

developments in project financing. Chapter 5 provides data on private investment trends and

near-term market forecasts.

Highlights of this report include:

• The global PV industry has seen impressive growth rates in cell/module production

during the past decade, with a 10-year compound annual growth rate (CAGR) of

46% and a 5-year CAGR of 56% through 2008. Global production reached 6.9 GW in

2008, led primarily by manufacturers in Europe, China, and Japan. China has realized

very high growth rates in recent years and was tied with Europe at 27% market share in

2008. The United States ranked fifth in 2008 at 6% market share or 0.41 GW of

production.

• Thin-film PV technologies have grown faster than crystalline silicon over the past

5 years, with a 10-year CAGR of 47% and a 5-year CAGR of 87% for thin-film

shipments through 2008. Global thin-film market share increased to 14% in 2008. The

United States was the global leader in thin-film production in 2008, with its top two

manufacturers both thin-film producers, First Solar (CdTe) and United Solar Ovonics or

Uni-Solar (a-Si). First Solar was the second-largest global PV producer in 2008.

• Global installed PV capacity increased by 6.0 GW in 2008, a 152% increase over

2.4 GW installed in 2007. The 2008 addition brought global cumulative installed PV

capacity to 13.9 GW. Leaders in 2008 capacity additions were Spain at 2.7 GW,

Germany at 1.5 GW, and the United States and Italy both at 0.34 GW. Germany

maintained its lead in cumulative installed capacity in 2008 with 5.3 GW, followed by

Spain at 3.4 GW, Japan at 2.1 GW, and the United States at 1.1 GW. The grid-connected

market accounted for 97% of 2008 capacity additions and 94% of cumulative installed

capacity in 2008.

• The United States installed 0.34 GW of PV capacity in 2008, a 63% increase over

0.21 GW in 2007. The 2008 addition brought U.S. cumulative installed PV capacity to

1.1 GW. California continued to dominate the market with nearly 180 MW installed in

2008, bringing cumulative installations to 530 MW or 67% of the U.S. market. New

Jersey followed with 23 MW installed in 2008, bringing cumulative capacity to 70 MW

or 9% of the U.S. market.

• Global average PV module prices dropped 23% from $4.75/W in 1998 to $3.65/W in

2008. Module prices rose slightly from 2002 to 2007 caused by polysilicon supply

constraints, but resumed their downward trend by decreasing from $4.07/W in 2007 to

$3.65/W in 2008. Capacity-weighted, average PV installation costs in the United States

x

decreased 31% from $10.8/W in 1998 to $7.5/W in 2008. The cost decline of $0.3/W

from 2007 to 2008 corresponds to a $0.42/W decline in module prices over the same

period, whereas installation cost reductions from 1998–2005 were largely attributable to

non-module costs (prices are given in real 2008$).

• Federal legislation, including the Emergency Economic Stabilization Act of 2008

(EESA, October 2008) and the American Recovery and Reinvestment Act (ARRA,

February 2009), is providing unprecedented levels of support for the U.S. solar

industry. The EESA and ARRA provide extensions and enhancements to the federal

investment tax credits (ITCs), including allowing utilities to claim the ITC, a new 30%

manufacturing ITC for solar and other clean energy technologies, and an option that

allows grants in lieu of tax credits for taxpaying corporate entities. The $787 billion

ARRA package includes additional funds for the DOE Loan Guarantee program, DOE

EERE programs, and other programs and initiatives. In addition to federal support, state

and local policies, incentives, rules and regulations, as well as financing developments

continue to encourage deployment of solar energy technologies.

• In 2008, global private-sector investment in solar energy technology topped $16

billion, including almost $4 billion invested in the United States. From 2004 to 2008,

global private sector investment increased more than 25-fold. Each of three major sources

of new investment, venture capital and private equity, debt, and public equity, grew at a

CAGR of more than 67%. Global venture capital and private equity investment in solar

grew at a 4-year CAGR of 68% from $539 million in 2004 to $4.34 billion in 2008. U.S.

venture capital and private equity investment increased from $61 million in 2004 to $2.3

billion in 2008, corresponding to a 4-year CAGR of 148%.

• Solar PV market forecasts made in early 2009 anticipate global PV production and

demand to increase fourfold between 2008 and 2012, reaching roughly 20 GW of

production and demand by 2012. Europe is expected to remain the largest market for

solar power, but the North American market is expected to grow the fastest. Module

prices are projected to decrease 34% from 2008 to 2010, and system prices are projected

to decrease 31% from 2008 to 2010.

• Globally, about 13 GW of CSP was announced or proposed through 2015, based on

forecasts made in mid-2009. Regional market shares for the 13 GW are about 51% in

the United States, 33% in Spain, 8% in the Middle East and North Africa, and 8% in

Australasia, Europe, and South Africa. Of the 6.5-GW project pipeline in the United

States, 4.3 GW have power purchase agreements (PPAs). The PPAs comprise 41%

parabolic trough, 40% power tower, and 19% dish-engine systems.

xi

Notes

• This report includes historical price information and forecasts of future prices. Past and

future prices can be provided as "current/nominal" (actual prices paid in the year stated)

or "real" (indexed to a reference year and adjusted for inflation). In some cases, the report

states whether prices are current/nominal or real. However, some of the published

analyses from which price information is derived do not report this distinction. In

practice, prices are usually considered to be current/nominal for cases in which the

distinction is not stated explicitly.

• In some tables and figures, the sum of numerical components is not equal to the total sum

shown due to rounding. Also, note that calculations such as growth rates were computed

before numbers were rounded and reported. Standard rounding conventions were used in

the report.

• Solar water heating, space heating and cooling, and lighting technologies are not covered

in this report. DOE supports these technologies through its Building Technologies

Program.

1

1. Installation Trends, Photovoltaic and Concentrating

Solar Power

This chapter presents global and U.S. trends in photovoltaic (PV) and concentrating solar power

(CSP) installations. Section 1.1 summarizes global installed PV capacity, growth in PV capacity

over the past decade, and market segmentation data such as interconnection status and sector of

application. Section 1.2 does the same for the U.S. market and includes a discussion of U.S.

states with the largest PV markets. Section 1.3 presents global and U.S. installed CSP capacity.

1.1 Global Installed PV Capacity

1.1.1 Cumulative Installed PV Capacity Worldwide

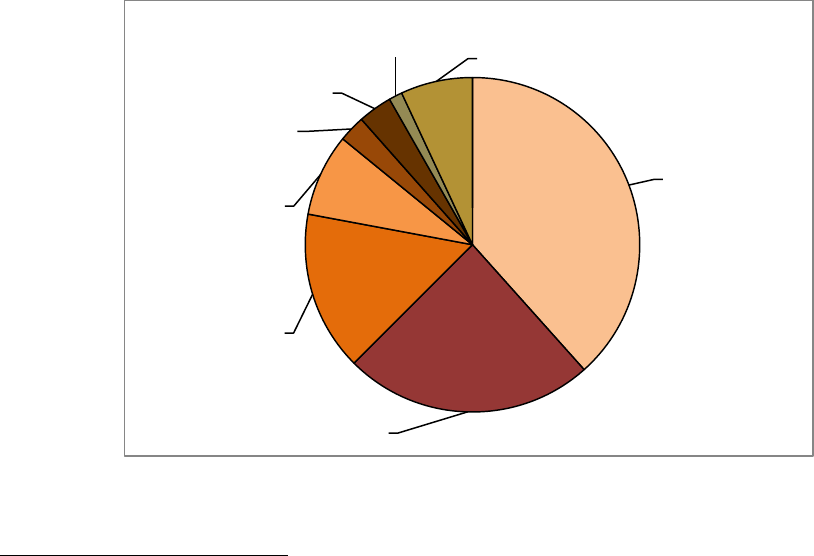

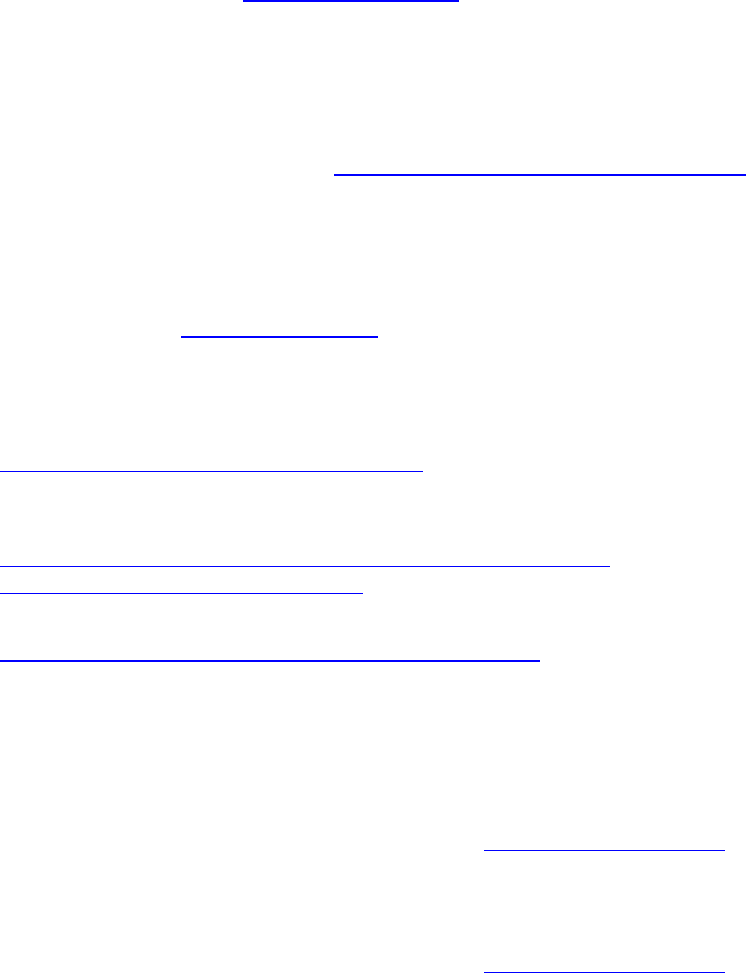

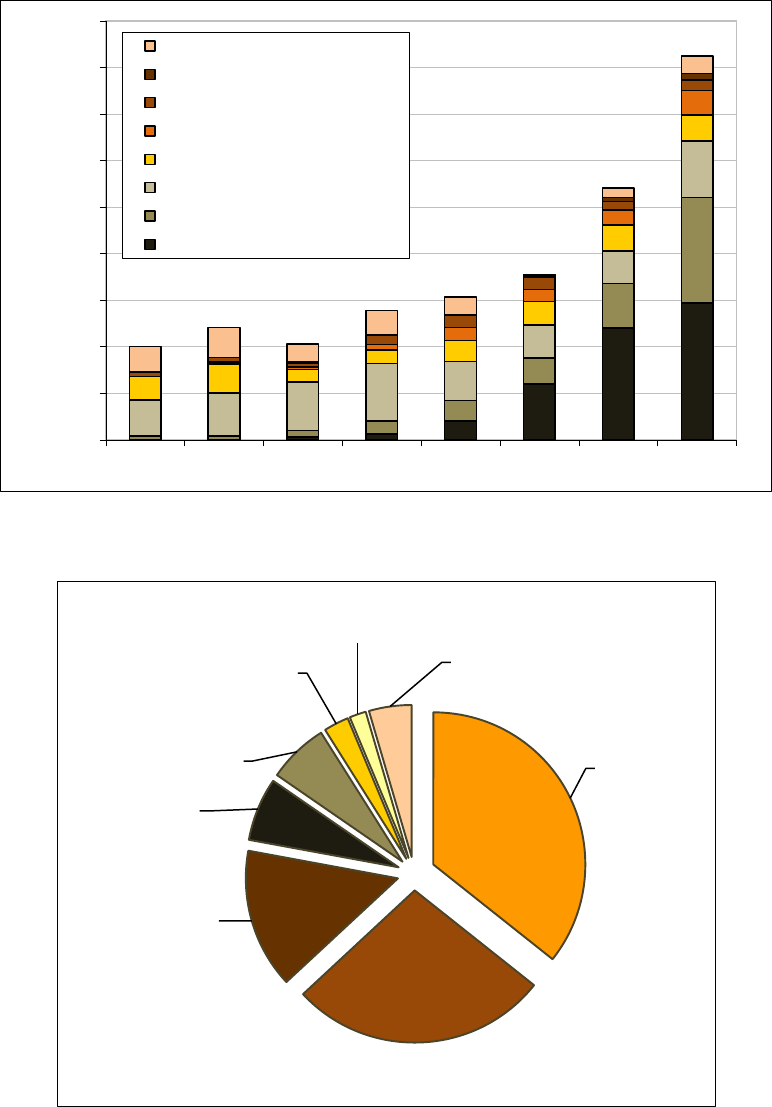

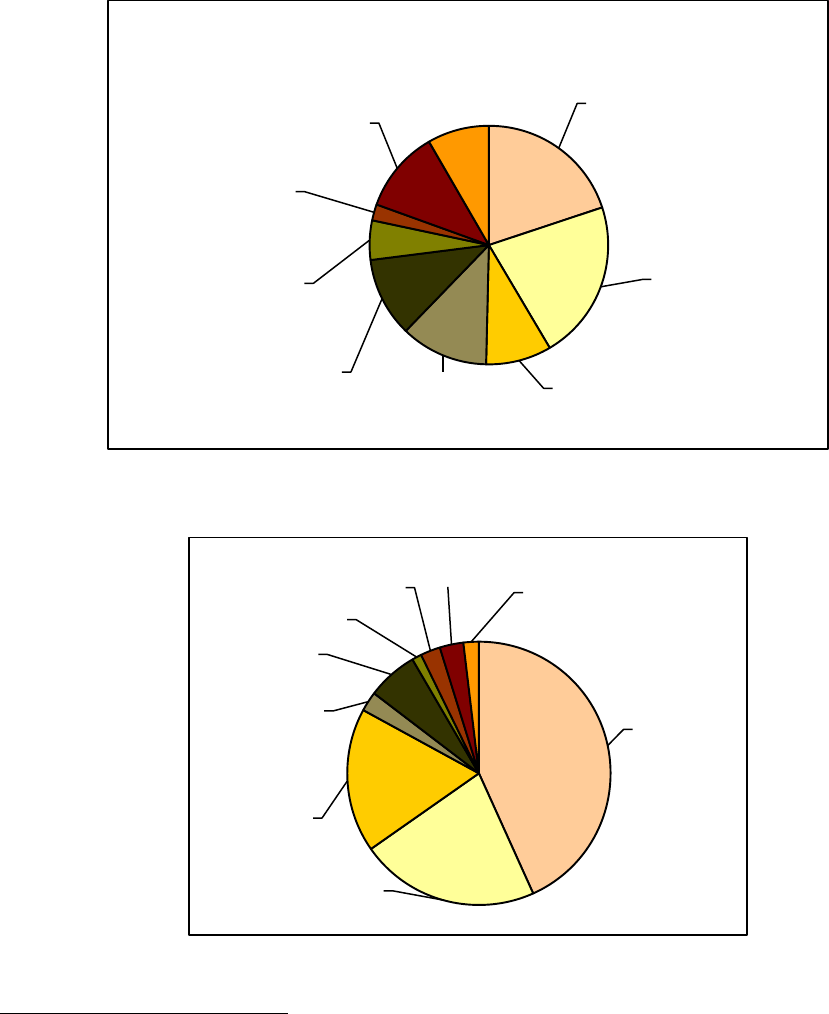

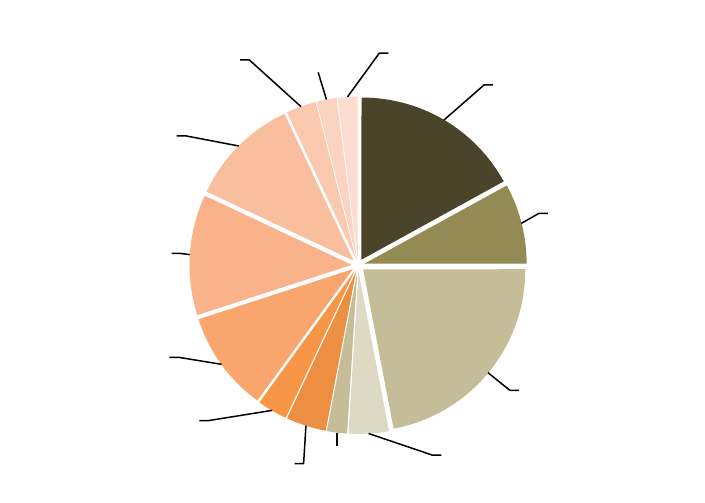

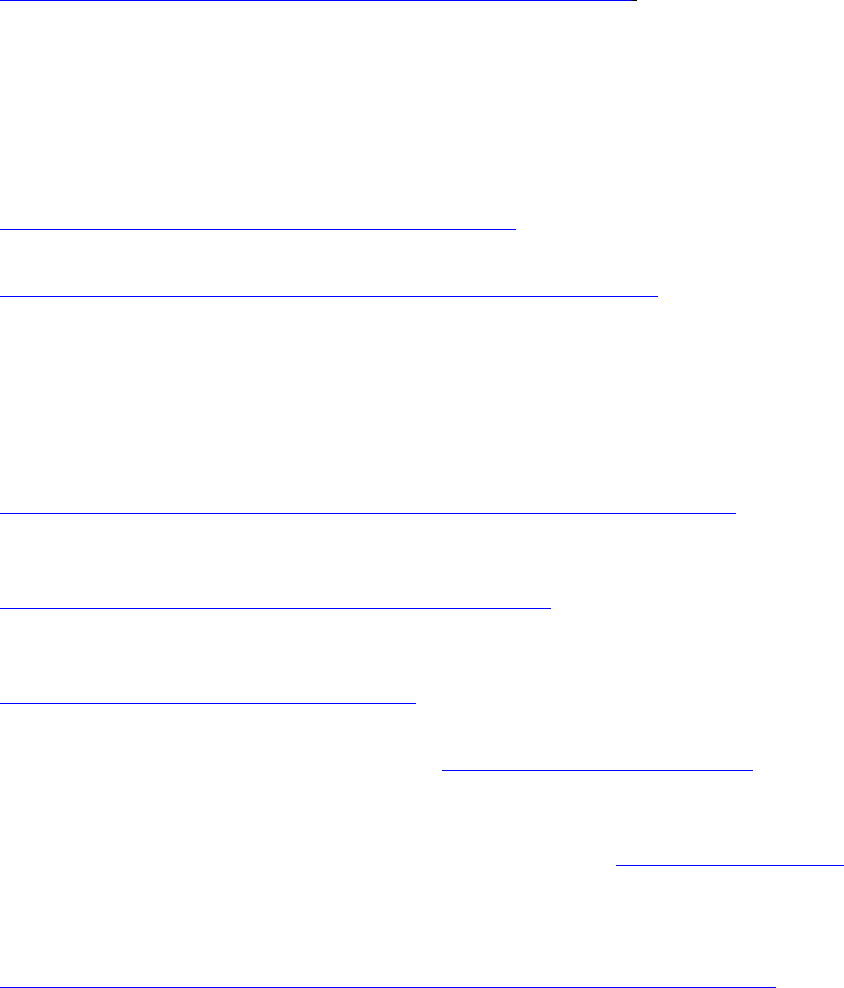

Cumulative installed PV capacity worldwide is 13.9 GW, with data from multiple sources

represented in Figure 1.1 (EurObserv’ER 2009, IEA 2009, Mints et al. 2009, Sherwood/IREC

2009).

1

Germany is the clear leader at 5.3 GW of cumulative installed capacity, followed by

Spain, Japan, the United States, Italy, South Korea, and France. Other European Union (EU)

countries contributed about 0.37 GW of the 0.97 GW attributed to the Rest of World (ROW)

countries.

2

The capacity of 13.9 GW is a 75% increase over 7.9 GW of 2007 cumulative

installed capacity, for a 2008 addition of approximately 6.0 GW. The 6.0 GW represents a 152%

increase over 2.4 GW installed in 2007.

Figure 1.1 Global cumulative installed PV capacity through 2008

(EurObserv’ER 2009, IEA 2009, Mints et al. 2009, Sherwood/IREC 2009)

1

Data for the top countries shown in Figure 1.1 are from IEA 2009. 2008 data for EU countries not included in IEA

2009 are from EurObserv’ER 2009 and contribute to the ROW total. U.S. data are from Larry Sherwood/IREC. The

estimate for ROW installed capacity and market share is based on data from IEA 2009 and EurObserv’ER 2009 for

countries not in the top seven; ROW demand share is from Mints et al. 2009.

2

The IEA 2009 report estimates global cumulative installed PV capacity through 2008 to be 13.4 GW. This is close

to the 13.9 GW shown in Figure 1.1, but Figure 1.1 also includes an overall ROW estimate as described in the

previous footnote.

Germany,

5.3 GW, 38%

Spain,

3.4 GW, 24%

Japan,

2.1 GW, 15%

United States,

1.1 GW, 8%

South Korea,

0.36, 3%

Italy,

0.46 GW, 3%

France,

0.18 GW, 1%

Rest of World,

0.97 GW, 7%

2

The range of estimates for cumulative installed PV capacity worldwide through 2008 is between

13 and 17 GW, with at least two sources at the upper end of the range (REN21 2009, Boas et al.

2009). The higher estimates likely represent cumulative production or shipments of PV cells and

modules. In a rapidly growing industry, it makes sense that cumulative production should be

greater than cumulative shipments, which should be greater than cumulative installed capacity.

Data presented in this report reflect cumulative global production of 18.5 GW from 1997 to

2008, cumulative global shipments of 15.2 GW from 1997 to 2008, and cumulative installed

capacity of 13.9 GW.

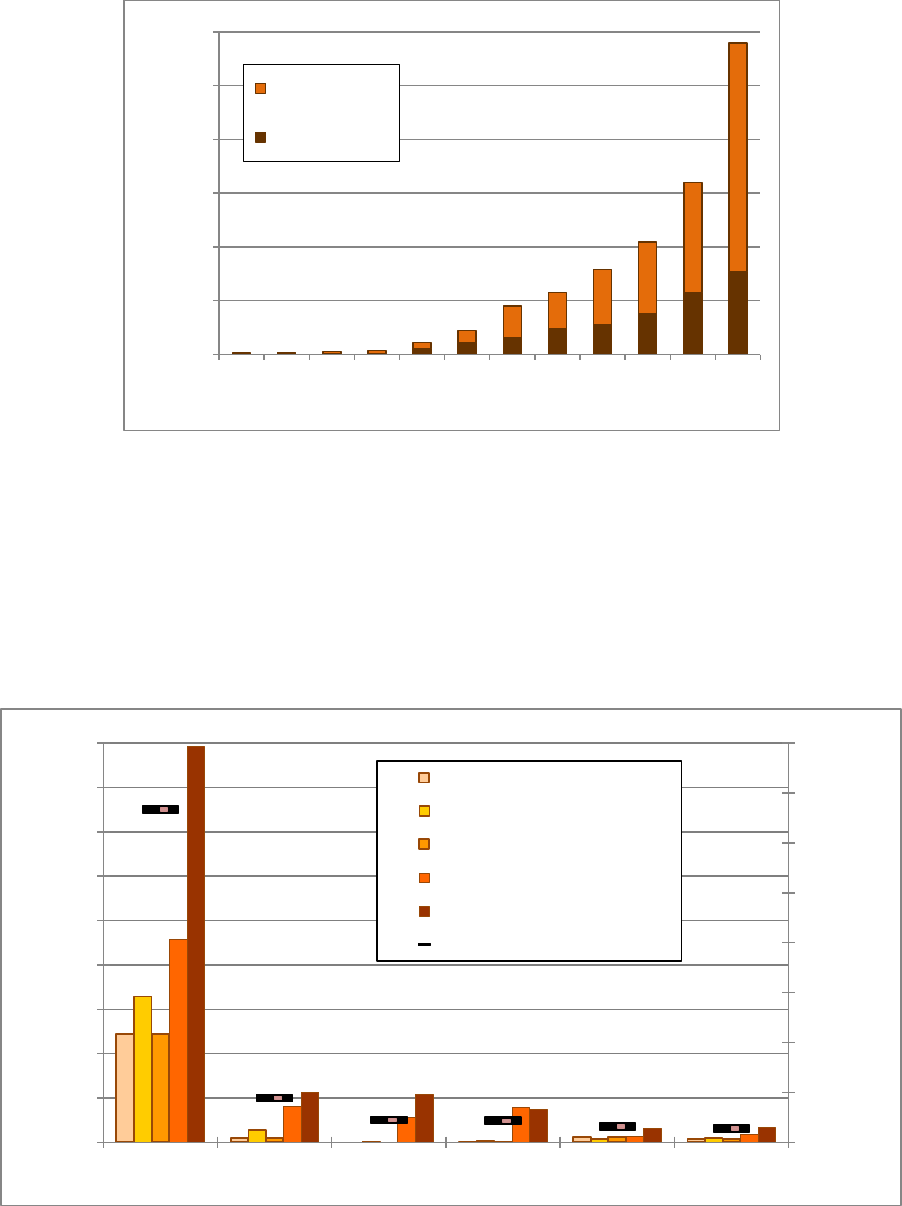

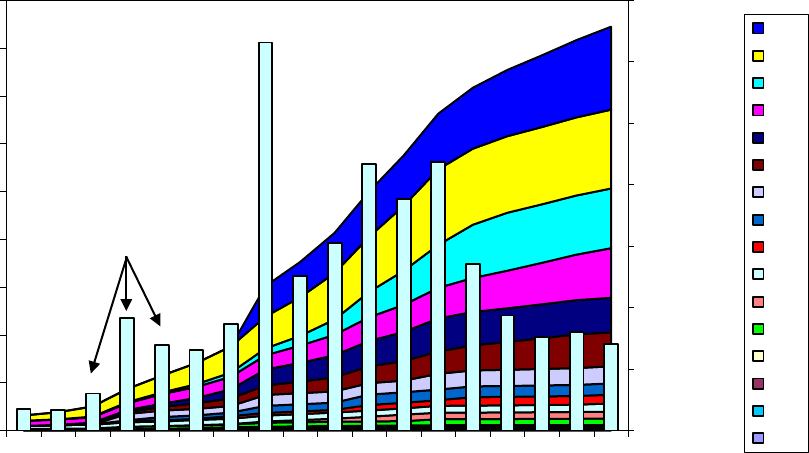

1.1.2 Growth in Cumulative and Annual Installed PV Capacity Worldwide

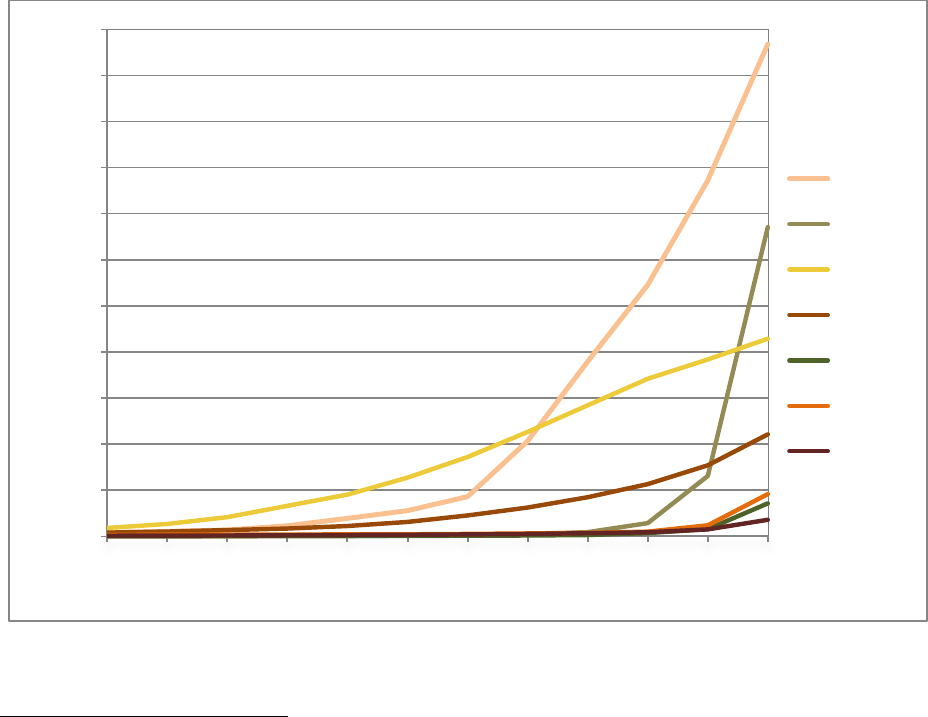

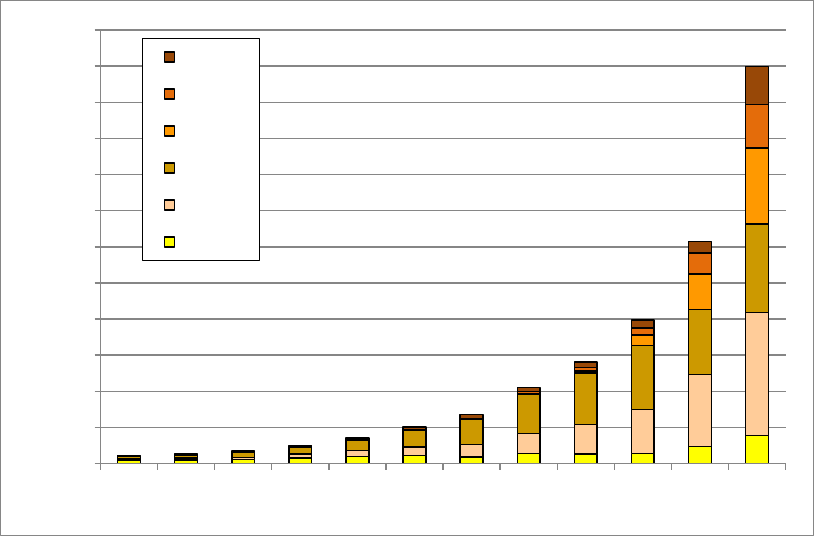

As illustrated in Figure 1.2, Germany’s cumulative installed PV capacity reached 5.3 GW as of

the end of 2008. This is a 38% increase over 2007 cumulative installed capacity of 3.9 GW.

Germany’s market for PV has been supported by a feed-in tariff (FIT) since 2000, providing a

guaranteed payment for a 20-year period for PV-generated electricity feeding into Germany’s

grid. Germany’s PV market experienced its highest annual growth year in 2004, a 290% increase

from 0.15 GW in 2003 to 0.60 GW in 2004, coinciding with an amendment enhancing and

streamlining Germany’s FIT (called Erneuerbare-Energien-Gesetz [EEG]).

3

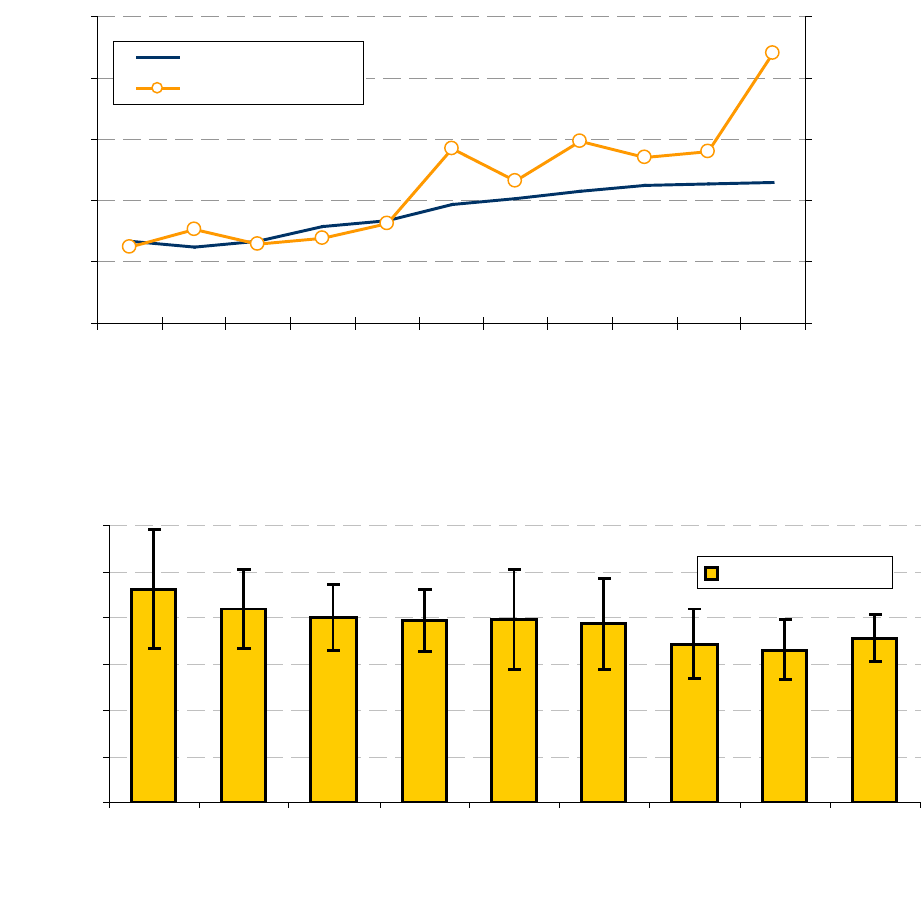

Figure 1.2 Cumulative installed PV capacity in top seven countries

(IEA 2008, IEA 2009, Sherwood/IREC 2009)

3

The revision to the EEG included an overall increase in the per-kWh payment for PV-generated electricity among

other adjustments such as the setting of degression

rates and the specification of payment rates according to PV-

system type (building versus ground mounted) and size.

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

Cumulative Installed Capacity (GW)

Germany

Spain

Japan

U.S.

Korea

Italy

France

3

Spain surpassed Japan in 2008 as the number two market as measured by cumulative installed

PV capacity of 3.4 GW, a 410% increase over Spain’s 2007 cumulative installed capacity of

0.66 GW. This tremendous increase in capacity was the result of support from Spain’s FIT. This

was the second year that Spain’s cumulative capacity grew by more than 300%. With 2006

cumulative capacity at 0.14 GW, growth to 0.66 MW in 2007 was a 360% increase.

Japan’s cumulative installed capacity reached 2.1 GW in 2008, an approximately 12% increase

over the 2007 level of 1.9 GW. Japan had the largest market for PV until Germany surpassed

Japan in 2005, coinciding with the end of Japan’s “70,000 Roofs” Program. Japan’s cumulative

installed capacity had reached 1.1 GW by the end of 2004, still greater than Germany’s 1.0 GW

at that time.

With U.S. policy support for PV via the federal investment tax credit, as well as state rebate

programs and other incentives and financing mechanisms, the U.S. PV market experienced a

43% increase in cumulative installed capacity, from 0.77 GW in 2007 to 1.1 GW in 2008.

Other leading markets include Italy, South Korea, and France, with 2008 cumulative installed PV

capacity reaching 0.46, 0.36, and 0.18 GW, respectively. This represents growth of 280% for

Italy (0.12 GW in 2007), 360% for South Korea (0.078 GW in 2007), and 140% for France

(0.075 GW in 2007).

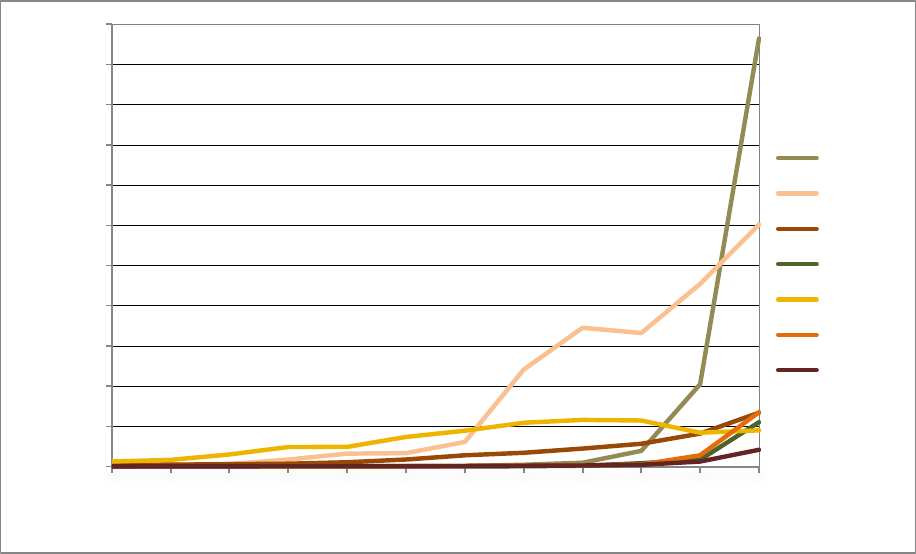

Figure 1.3 presents annual installed PV capacity from 1997–2008 for the seven leading

countries. Spain led in 2008, adding 2.7 GW, an increase of 420% over 0.51 GW installed in

2007. Germany added 1.5 GW in 2008, an increase of 33% (1.1 GW added in 2007). The United

States and Italy were third with 0.34 GW of 2008 additions, a 63% increase for the United States

(0.21 GW added in 2007) and a 380% increase for Italy (0.070 GW added in 2007).

Figure 1.3. Annual installed PV capacity in top seven countries

(IEA 2008, IEA 2009, Sherwood/IREC 2009)

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

2.75

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

Annual Installed PV Capacity (MW)

Spain

Germany

U.S.

Korea

Japan

Italy

France

4

Other leading markets were South Korea, Japan, and France. South Korea’s annual additions

topped Japan’s, increasing from 0.043 GW in 2007 to 0.28 GW in 2008 (540% growth). Japan

added 0.23 GW, an increase of 7% over the 2007 level of 0.21 GW. France added 0.10 GW in

2008, a 230% increase over the 0.031 GW installed in 2007.

1.1.3 Worldwide PV Installations by Interconnection Status and Application

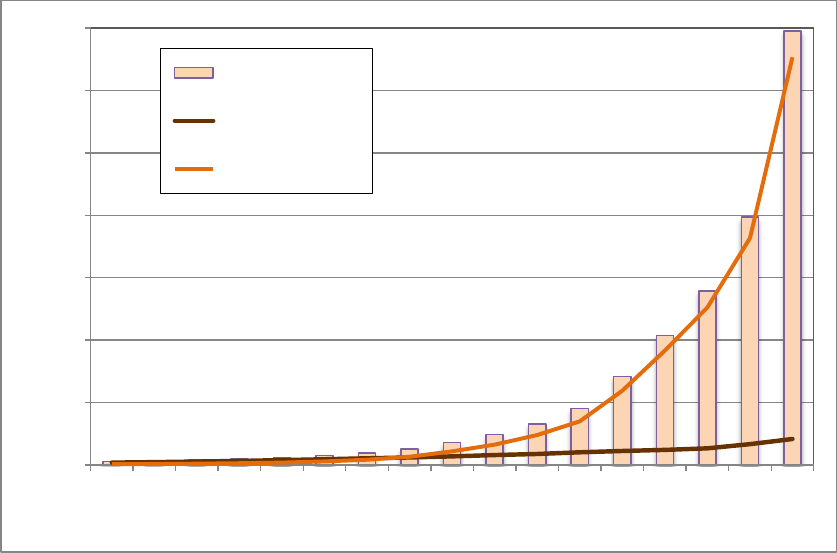

As illustrated in Figure 1.4, grid-connected PV has represented the majority of installed capacity

additions worldwide since about 1999, increasing its cumulative market share each year: 44% in

1998, 52% in 1999, nearly 92% in 2007, and 94% in 2008. The grid-connected market

contributed 97% of 2008 capacity additions. The faster growth in the grid-connected PV market

has been supported by incentives for grid-connected PV in the top global markets. The grid-

connected market grew at 10- and 5-year CAGRs of 54% and 56%, respectively, while the off-

grid market grew at 10- and 5-year CAGRs of 14% and 15%, respectively.

Grid-connected, cumulative installed capacity represented in Figure 1.4 grew nearly 80% from

7.3 GW in 2007 to 13.1 GW in 2008. Off-grid capacity grew 24% from 0.67 GW in 2007 to

0.83 GW in 2008. Grid-connected markets are typically easier to track than off-grid, because

grid-connected data associated with incentive programs are generally available, whereas off-grid

data are often elusive.

Figure 1.4. Global cumulative installed PV capacity by interconnection status

(EurObserv’ER 2009, IEA 2008, IEA 2009)

0

2

4

6

8

10

12

14

1992

1993

1994

1995

1996

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

Cumulative Installed Capacity (GW)

Total

Off-grid

Grid-Connected

5

The continued success of Germany’s PV market and the recent high rates of growth in Spain and

Italy are due largely to support in the form of FITs. This production incentive has greatly

motivated the installation of rooftop, grid-connected PV and large PV power plants in Germany,

large-scale PV plants in Spain, and grid-connected distributed generation in Italy (IEA 2008).

Incentives in the United States and other top markets have also greatly favored grid-connected

additions.

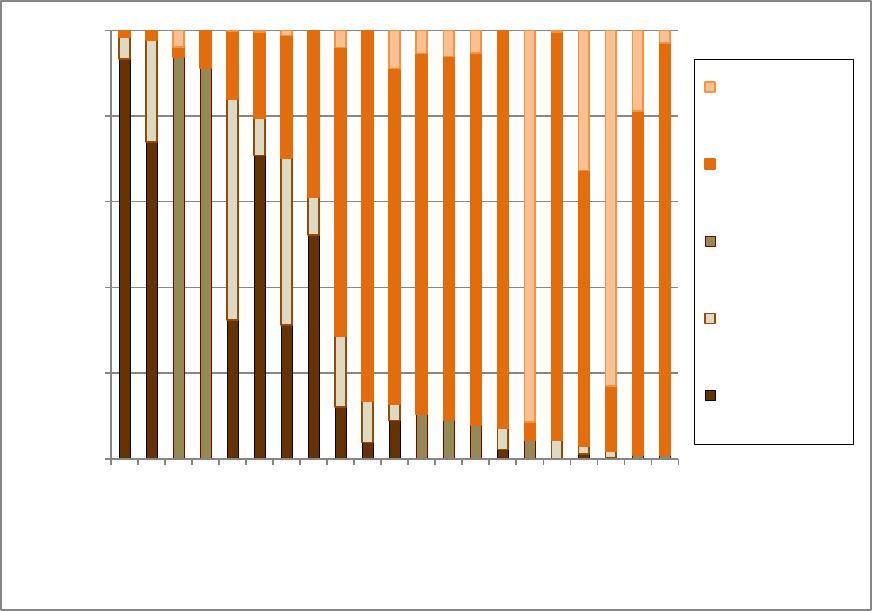

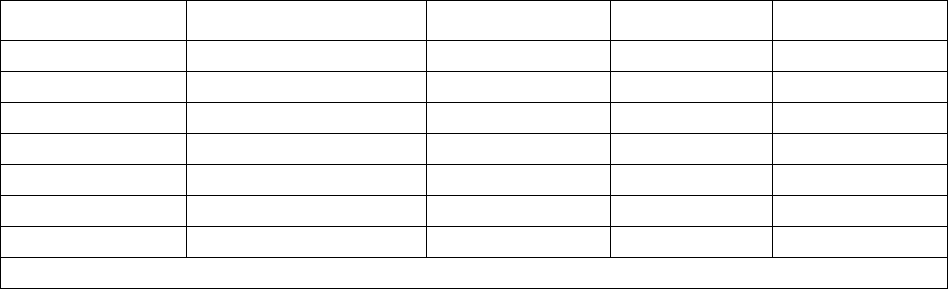

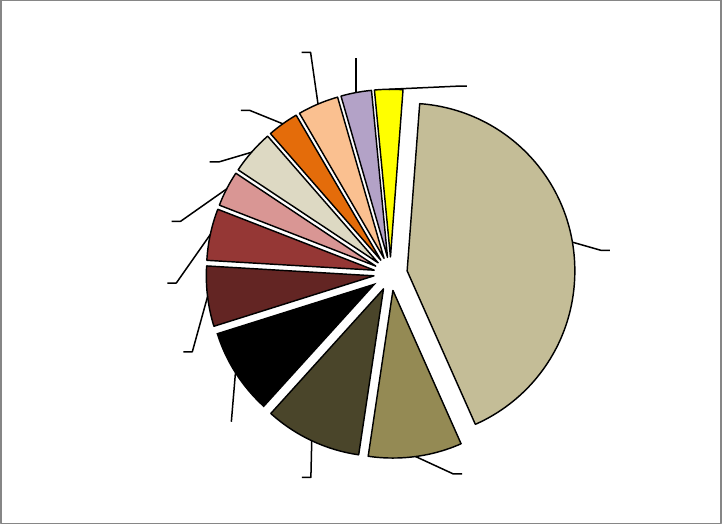

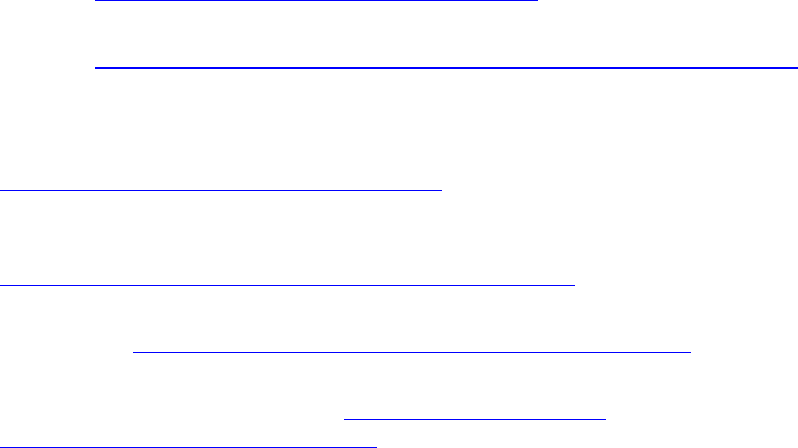

Despite dominance of the grid-connected market worldwide, there is still variation in the types of

PV systems installed in different countries, reflecting various types of subsidy support, market

maturity, demand for particular applications, and various economic and cost factors. More than

half of the countries listed in Figure 1.5 have a majority of grid-connected PV, including

Germany, Spain, Japan, South Korea, Italy, and the United States (toward the right side of the

graph). Cumulative installed capacity for countries such as Sweden, Israel, Malaysia, Turkey,

Mexico, and Norway (shown to the left of the United States on the graph) have a dominant off-

grid residential market. In Canada and Australia, significant portions of the PV markets consist

of off-grid commercial PV installations. In Australia, this capacity consists mainly of off-grid

industrial and agricultural applications (IEA 2009).

Figure 1.5. Application market share of cumulative installed PV capacity

in IEA countries through 2008

(IEA 2009, Mints 2009)

0%

20%

40%

60%

80%

100%

Norway

Mexico

Turkey

Malaysia

Canada

Israel

Australia

Sweden

US

Denmark

France

Austria

Netherlands

Switzerland

Great Britain

Portugal

Japan

Italy

South Korea

Spain

Germany

Market share of cumulative installed PV capacity

Grid-connected

utility

Grid-connected

distributed

Off-grid

undefined

Off-grid

non-domestic

Off-grid

domestic

6

1.2 U.S. Installed PV Capacity

1.2.1 Cumulative U.S. Installed PV Capacity

Cumulative installed PV capacity

4

in the United States topped 1 GW in 2008, increasing 43%

from 0.77 GW in 2007 to 1.1 GW by the end of 2008 (Sherwood/IREC 2009).

5

Enhanced government support on both the federal and state levels has been critical for expanding

the adoption of solar energy in the United States since 2005. The Energy Policy Act of 2005

(EPACT 2005) raised the federal investment tax credit (ITC) for solar from 10% to 30% for

nonresidential installations and from 0% to 30% for residential installations. EPACT 2005

capped the ITC for residential solar installations at $2,000, but this cap was removed by the

Emergency Economic Stabilization Act of 2008 (EESA), effective January 1, 2009. On the state

level, large incentive programs, such as the California Solar Initiative (CSI) and New Jersey’s

Consumer On-site Renewable Energy Program, offered rebates covering a significant proportion

of the up-front costs of PV systems. Other state and local policies, such as renewable portfolio

standards (RPSs) and improved interconnection and net metering rules, have further promoted

the growth of solar energy in recent years.

U.S. PV

installation growth has been accelerating in recent years. The United States installed 0.34 GW in

2008, an annual increase of 63% over 0.21 GW installed in 2007. Growth in annual additions

from 0.14 GW in 2006 to 0.21 GW in 2007 was 44%, and the 5-year CAGR for annual additions

from 2003 to 2008 was 37%.

1.2.2 U.S. PV Installations by Interconnection Status

In the United States, cumulative, installed off-grid PV capacity was higher than grid-connected

capacity until 2004 (Figure 1.6). The grid-connected market has since dominated and continued

to increase its market share (65% in 2007, 71% in 2008), which is due to federal and state

incentive support. Of the 1.1 GW of cumulative installed PV capacity in 2008, an estimated

0.79 GW are grid connected and 0.32 GW are off grid.

4

Includes grid-connected and off-grid installed PV capacity.

5

The U.S. installed PV capacity data presented in this report are based on data from Larry Sherwood, with the full

reference to his report, U.S. Solar Market Trends 2008,

http://irecusa.org/irec-programs/publications-reports/,

provided at the end of Chapter 1. Note that the numbers presented in this chapter are slightly different from those in

Sherwood’s report, as the data used for this report were obtained directly from him in June 2009.

7

Figure 1.6. U.S. cumulative installed PV capacity by interconnection status

(Sherwood/IREC 2009)

1.2.3 U.S. PV Installations by Application and Sector

In addition to grid-connected versus off-grid, PV installations can be categorized by application,

including building-integrated, rooftop, and ground-mounted PV, and sector, which comprises

residential, commercial, and utility markets.

As shown in Figure 1.7, rooftop PV installations were estimated at 64% or nearly two-thirds of

U.S. installations in 2008. Assuming 0.34 GW or about 340 MW installed in the United States in

2008, as stated in Section 1.2.1, rooftop installations amounted to nearly 218 MW.

Figure 1.7. U.S. PV applications, 2008 market shares

(EuPD Research 2008)

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

Cumulative Installed Capacity (GW)

Total

Off-Grid

Grid-Connected

64%

10%

3%

22%

Rooftop

Roof-

integrated

Façade-

integrated

Ground-

mounted

8

During the past couple of years, there has been an increase in the installation of ground-mounted

PV systems. The Boulder City, Nevada, 10-MW, ground-mounted PV project, which came

online in December 2008, is the largest thin-film solar power plant in North America. The

project was developed by Sempra Generation and consists entirely of First Solar thin-film

modules (First Solar 2008). Large ground-mounted PV systems were also installed in 2007 at

Nellis Air Force Base in Nevada (14 MW) and Alamosa, Colorado (8 MW). Only one new large

installation came online in 2008, but many new ground-mounted projects began development in

2008. Examples are Pacific Gas & Electric’s 550-MW Topaz Solar Farm and the 250-MW

California Valley Solar Ranch (Bradford et al. 2008). Large PV systems are expected to increase

in market share, supported by the utilities’ need to meet renewable portfolio standard (RPS) and

solar set-aside requirements and their recently legislated ability to utilize the federal ITC

(expanded ITC passed October 2008).

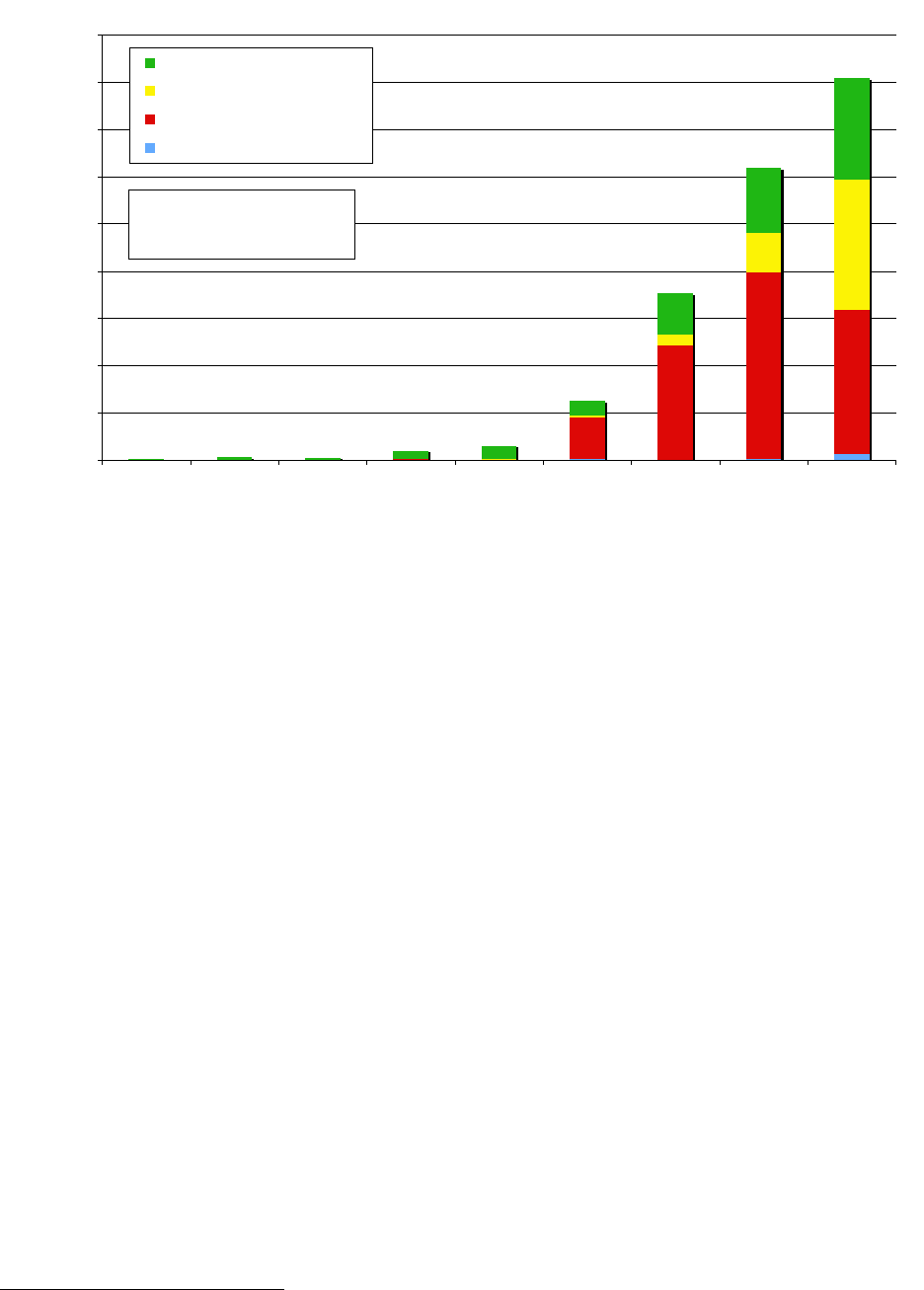

Figure 1.8 shows that although the number of nonresidential installations including commercial

and utility PV is increasing, the residential sector still accounts for the vast majority of annual

installations. In 2008 nearly 17,000 grid-connected residential installations were installed,

compared to fewer than 2,000 grid-connected nonresidential PV installations.

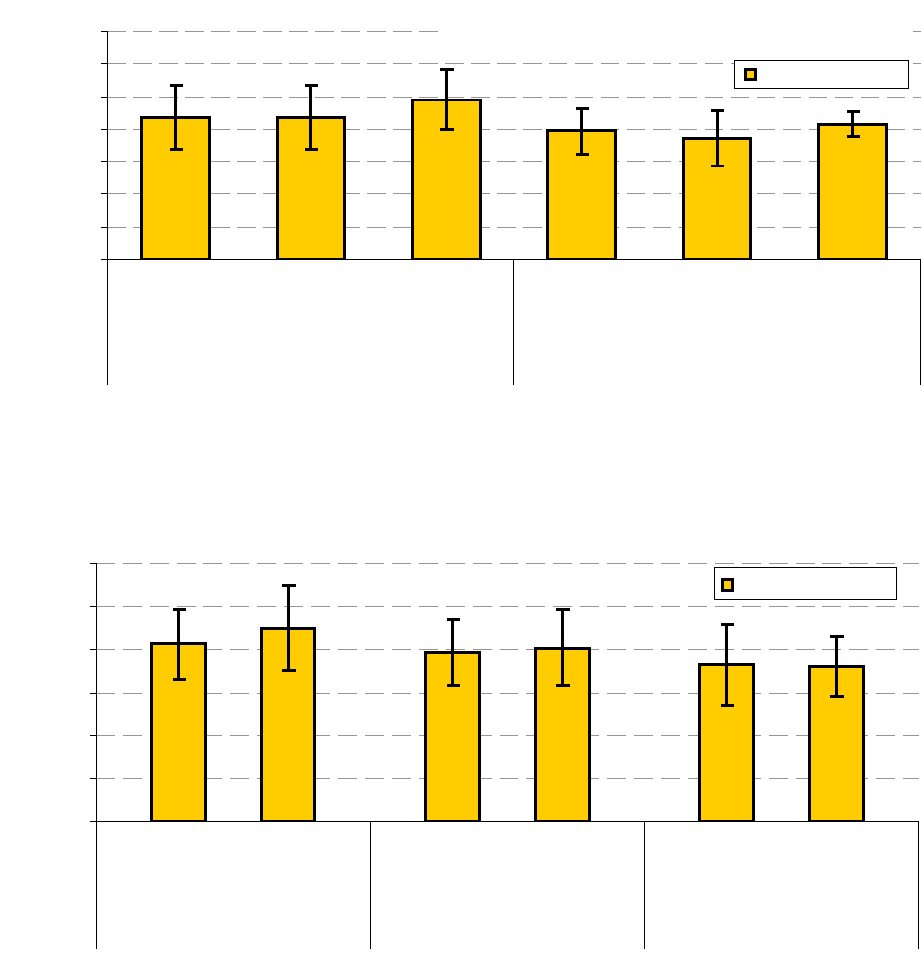

Figure 1.8. Annual trend in number of U.S. grid-connected PV installations by sector

(Sherwood/IREC 2009)

Although grid-connected residential PV installations have greatly outnumbered grid-connected

nonresidential PV installations for almost a decade, the annual capacity added by new

nonresidential PV installations is much greater because of larger system sizes in the commercial

and utility sectors. As indicated in Figure 1.9, the additional capacity from grid-connected

nonresidential installations accounted for 73% of the 0.29 GW (or 290 MW) of grid-connected

capacity added in 2008.

0

2,000

4,000

6,000

8,000

10,000

12,000

14,000

16,000

18,000

20,000

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

Annual Number of Installations

Nonresidential

Residential

9

Figure 1.9. U.S. annual grid-connected PV capacity

(Sherwood/IREC 2009)

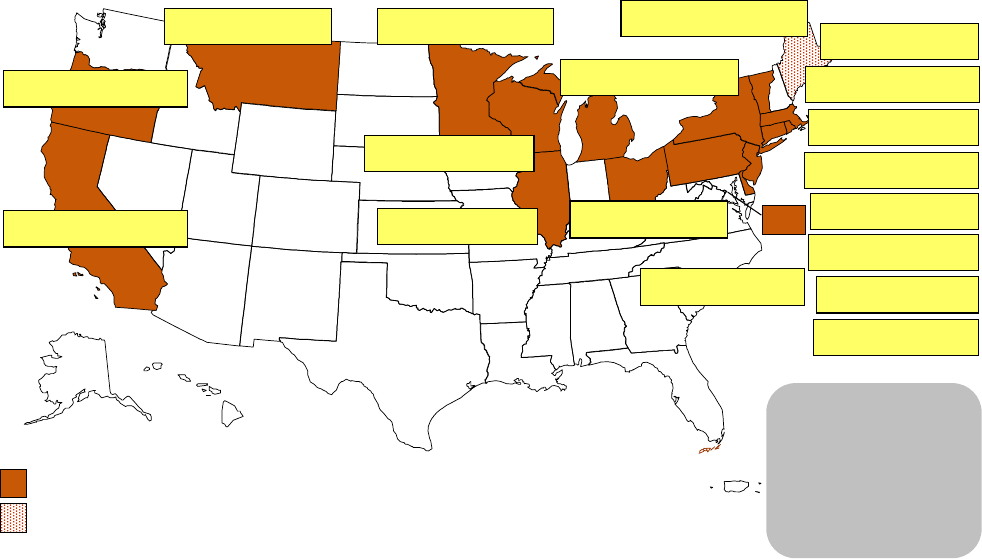

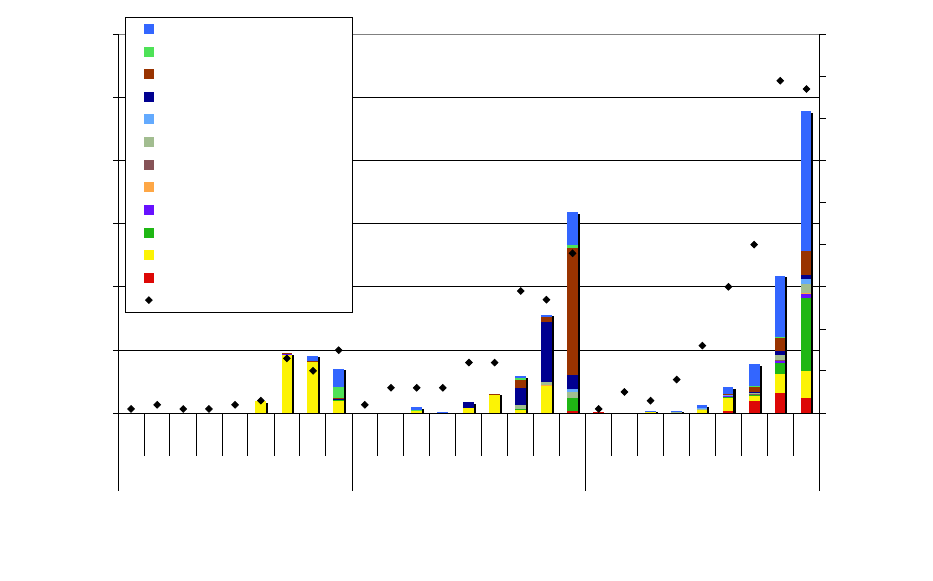

1.2.4 U.S. States with the Largest PV Markets

The top six states in terms of cumulative, installed grid-connected PV capacity as of the end of

2008 were California (530 MW, 67% market share), New Jersey (70 MW, 9% market share),

Colorado (36 MW, 4.5% market share), Nevada (34 MW, 4% market share), Arizona (25 MW,

3% market share), and New York (22 MW, 3% market share).

Figure 1.10. Annual grid-connected PV capacity and cumulative market share

in top U.S. state markets, 2004–2008

(Sherwood/IREC 2009)

0

50

100

150

200

250

300

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

Annual Installed Capacity (MW)

Nonresidential

Residential

0%

10%

20%

30%

40%

50%

60%

70%

80%

0

20

40

60

80

100

120

140

160

180

California

New Jersey

Colorado

Nevada

Arizona

New York

Cumulative Market Share (%)

Annual Installed Capacity (MW)

2004

2005

2006

2007

2008

Cumulative Market Share

10

Figure 1.10 shows annual installed capacity for the top six states for the past 5 years. California

continued to lead the U.S. market with nearly 180 MW of new grid-connected PV in 2008,

representing 95% growth from the 92 MW installed in 2007. In New Jersey, 23 MW of new

capacity were installed in 2008, amounting to 37% annual growth from the 16 MW installed in

2007. Colorado’s annual capacity additions increased 88% from 11 MW installed in 2007 to

22 MW installed in 2008. Annual installed capacity in Nevada decreased slightly from 16 MW in

2007 to 15 MW in 2008, with most new capacity coming from the 10-MW El Dorado project.

Arizona continued to see steady growth with a 130% increase in installed capacity, from 2.8 MW

in 2007 to 6.4 MW in 2008. In New York, 7 MW were installed in 2008, an 85% increase over

the 3.8 MW installed in 2007.

1.3 Global and U.S. Installed CSP Capacity

1.3.1 Cumulative Installed CSP Worldwide

At the end of 2008, there were 430 MW of cumulative, grid-tied concentrating solar power

(CSP) capacity worldwide, with more than 95% (419 MW) of this global capacity located in the

southwestern United States. By July 2009, global capacity increased to about 550 MW with the

addition of 120 MW in Spain. This reduced the U.S. share to approximately 75%. Of the

550 MW of CSP worldwide, nearly 95% (519 MW) is parabolic trough technology, with the

remainder (31 MW) being tower technology. Table 1.1 lists installed CSP plants worldwide as of

July 2009.

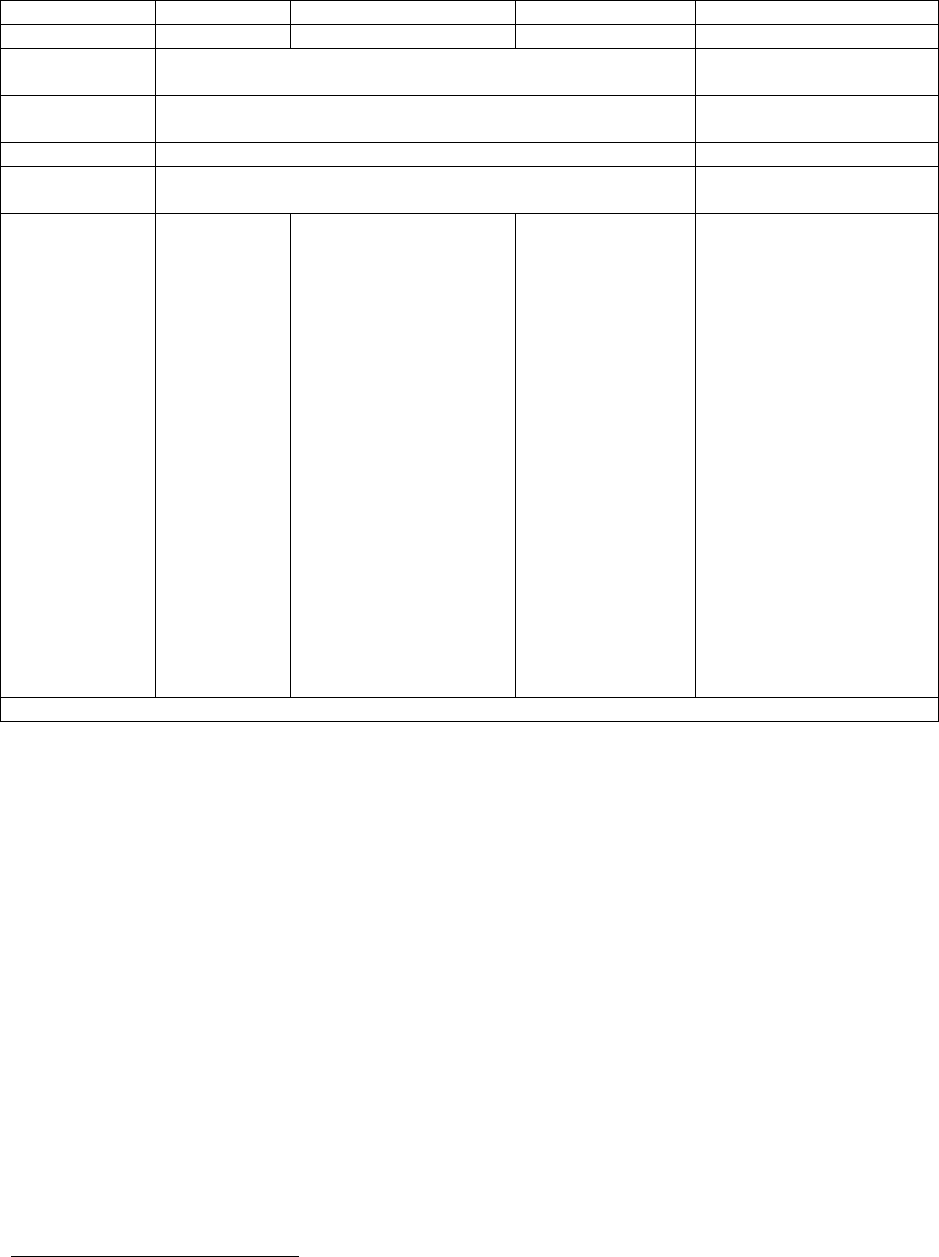

Table 1.1. Global Installed CSP Plants

Plant Name Location Technology Type Year Installed Capacity (MW)

SEGS I - IX

California, United States

Trough

1985–1991

354

APS Saguaro

Arizona, United States

Trough

2005

1

Nevada Solar One

Nevada, United States

Trough

2007

64

PS10

Spain

Tower

2007

11

Puertollano Plant

Spain

Trough

2009

50

Andasol I

Spain

Trough

2009

50

PS20

Spain

Tower

2009

20

Grama et al. 2008

1.3.2 Major non-U.S. International Markets for CSP

Besides the United States, Spain and North Africa are promising markets for CSP. The first

commercial CSP plant in Spain, the 11-MW tower system known as PS10, was completed in

2007. With a 25% capacity factor, PS10 can generate 24 GWh/yr, enough to supply about 5,500

households with electricity (Grama et al. 2008). No new systems were connected to the grid in

Spain in 2008.

As of July 2009, nearly 400 MW of CSP capacity, mostly trough systems, were under

construction in Spain, supported by the government’s feed-in tariff (FIT) policy, which

guarantees payment for electricity produced by a CSP system. The FIT has two major

restrictions. First, the maximum allowable size of a plant is 50 MW. Second, there is an overall

11

capacity ceiling of 500 MW. During the first half of 2009, construction was completed on the

50-MW Andasol I trough plant and the 50-MW Puertollano trough plant (Solar Millennium

2009, CSP Today 2009). Andasol I became the first commercial CSP plant with energy-storage

capability designed specifically for electricity generation after sunset. This added feature enables

the plant to provide electricity for ~7.5 hours after sunset (Solar Millennium 2009).

The region of North Africa has the potential for sizable CSP growth. Feasibility studies show

that North African power plants could provide about 15% of Europe's electricity needs. One of

the requirements for this to occur is the construction of a 2,000-mile transmission cable

connecting the two continents (Merrill Lynch 2008). Discussion on the matter has occurred, but

major policy decisions have yet to be made. In Morocco, 20 MW of CSP will be hybridized with

a natural gas plant (Global Environment Facility 2009), and similar planning is under way in

Algeria and Egypt. This type of design, known as an integrated solar combined cycle (ISCC), is

gaining some traction in the region. An ISCC plant combines heat from the natural gas turbine

and the solar field, achieving capacity gains without increasing emissions. Another benefit of

such a system is that an additional turbine is not needed when the CSP portion is built. This both

speeds up the construction process and helps keep capital expenditures in check.

On the global level, nearly 600 MW of CSP were in the engineering, procurement, and

construction stages by the end of 2008 (Grama et al. 2008), as summarized in Table 1.2. The

majority were trough systems being built in Spain, with North African countries installing trough

and tower capacity as part of ISCC plants. Mexico and China were also constructing trough

systems.

Table 1.2. CSP Plants Under Construction, by Country

Country

Technology Type

Capacity (MW)

Algeria

Trough

43

Australia Linear Fresnel Reflector 1

China

Trough

50

Egypt Tower 31

Mexico

Trough

29

Morocco Trough 30

Spain

Trough

350

Spain Tower 37

Total

571

Grama et al. 2008

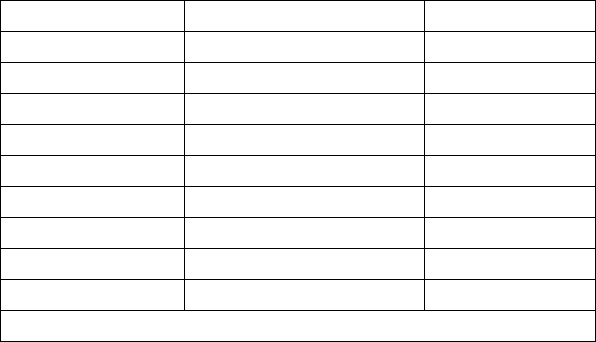

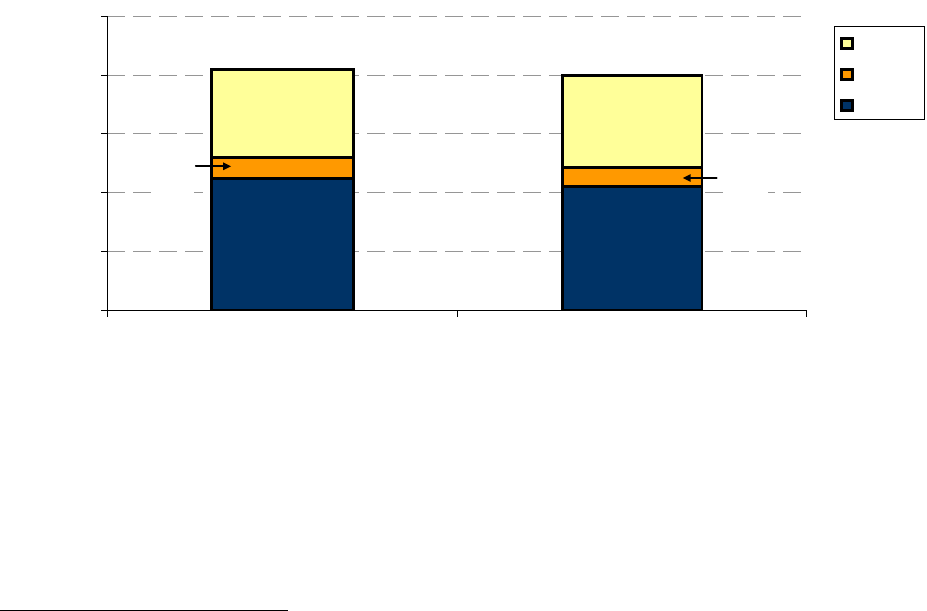

1.3.3 U.S. Installed CSP Capacity

As of the end of 2008, 419 MW of grid-tied CSP capacity had been installed in the southwestern

United States, accounting for more than 95% of global CSP capacity. The Solar Electricity

Generating Stations (SEGS) in the Mojave Desert of southern California account for 354 MW of

this capacity. SEGS comprises nine parabolic trough plants, ranging from 14 to 80 MW, located

in three main locations (Daggett, Harper Lake, and Kramer Junction); this is illustrated in

Figure 1.11. The plants were built between 1984 and 1991 and together have generated more

than 11,000 GWh (BrightSource 2008).

12

Figure 1.11. Concentrating solar power plants of the southwest United States

(NREL 2009)

As summarized in Table 1.3, the next CSP plant to come online in the United States after the

SEGS plants was the Arizona Public Service (APS) Saguaro 1-MW parabolic trough plant.

Installed in Red Rock, Arizona, in 2005, the system has a capacity factor of 23%, allowing for

the generation of 2 GWh per year (Grama et al. 2008). Another 64 MW of CSP capacity are

accounted for by the Nevada Solar One parabolic trough plant in Boulder City, Nevada.

Connected to the grid in 2007, this plant has a capacity factor of 23% and generates more than

130 GWh each year (Acciona Energy 2008, Grama et al. 2008). The estimated cost of electricity

generated by the Nevada Solar One plant is about $0.18/kWh (Bullard et al. 2008).

Table 1.3. Installed CSP Plants in the United States

Plant Name

Location

Technology

Type

Year

Installed

Capacity

(MW)

SEGS I

Daggett, CA

Trough

1985

14

SEGS II

Daggett, CA

Trough

1986

30

SEGS III

Kramer Junction, CA

Trough

1987

30

SEGS IV

Kramer Junction, CA

Trough

1987

30

SEGS V

Kramer Junction, CA

Trough

1988

30

SEGS VI

Kramer Junction, CA

Trough

1989

30

SEGS VII

Kramer Junction, CA

Trough

1989

30

SEGS VIII

Harper Lake, CA

Trough

1990

80

SEGS IX

Harper Lake, CA

Trough

1991

80

APS Saguaro

Saguaro, AZ

Trough

2005

1

Nevada Solar One

Boulder City, NV

Trough

2007

64

Total

419

Grama et al. 2008

Nevada Solar One, 64MW

APS Saguaro, 1MW

SEGS III-VII, 150MW

SEGS I & II, 44 MW

SEGS VIII & IX, 160MW

13

1.4 References

Acciona Energy. (2008). www.acciona-na.com/. Accessed November 2008.

Boas, R.; Farber, M.; Flynn, H.; Meyers, M.; Porter, C.; Rogol, M.; Song, J. (March 2009).

Photon International. “Looking back—sizing the 2008 solar market.” pp. 88–93.

Bradford, T.; Englander, D.; Maycock, P. (June 2008). “The Growth of Utility Scale PV.” PV

News. Prometheus Institute and Greentech Media.

BrightSource Energy, Inc. (2008). www.brightsourceenergy.com/bsii/history/. Accessed

November 2008.

Bullard, N.; Chase. J.; d’Avack, F. (May 20, 2008). “The STEG Revolution Revisited.” Research

Note. London: New Energy Finance.

CSP Today. (May 12, 2009). “Iberdrola launches its first solar thermal power plant.” Weekly

Intelligence Brief. www.csptoday.com/. Accessed May 2009.

EuPD Research. (2008). Photovoltaics in the USA: Detailed Analysis of a future solar market,

management summary. Bonn, Germany: EuPD.

EurObserv’ER. (2009). Photovoltaic Barometer. Paris, France: EurObserv’ER Consortium.

http://www.eurobserv-er.org/downloads.asp. Accessed July 2009.

First Solar Inc. (December 22, 2008). “First Solar Completes 10MW Thin Film Solar Power

Plant for Sempra Generation.” News Release.

http://investor.firstsolar.com/phoenix.zhtml?c=201491&p=irol-

newsArticle&ID=1238556&highlight=. Accessed November 25, 2009.

Global Environment Facility. (2009). GEF Project Database.

http://gefonline.org/projectDetailsSQL.cfm?projID=647. Accessed July 2009.

Grama, S.; Wayman, E.; Bradford, T.; (2008) Concentrating Solar Power—Technology, Cost,

and Markets. 2008 Industry Report. Cambridge, MA: Prometheus Institute for Sustainable

Development and Greentech Media.

International Energy Agency (IEA). (2008). Trends in photovoltaic applications: Survey report

of selected IEA countries between 1992 and 2007. Report IEA-PVPS T1-17: 2008. IEA

Photovoltaic Power Systems Programme (PVPS). http://www.iea-pvps.org/ Accessed February

2009.

International Energy Agency (IEA). (2009). Trends in photovoltaic applications. Survey report

of selected IEA countries between 1992 and 2008. Report IEA PVPS T1-18:2009. IEA

Photovoltaic Power Systems Programme (PVPS). http://www.iea-pvps.org/ Accessed November

2009.

Merrill Lynch. (2008). Solar Thermal: Not Just Smoke and Mirrors. New York, NY: Merrill

Lynch.

Mints, P.; (2009). Analysis of Worldwide Markets for Photovoltaic Products and Five-Year

Application Forecast 2008/2009. Report # NPS-Global4. Palo Alto, CA: Navigant Consulting

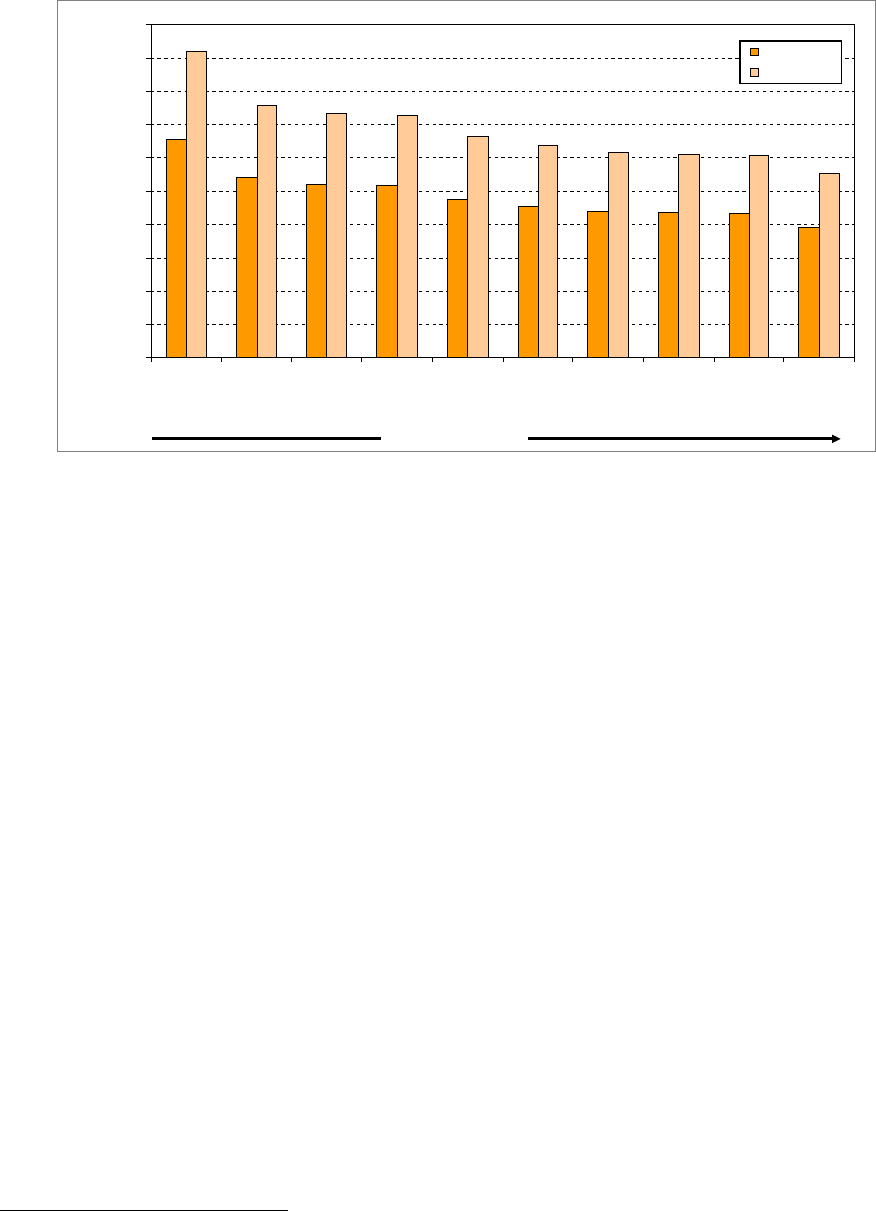

Photovoltaic Service Program.

Mints, P.; Pogrebnyak, L.; Burmon, A. (February 23, 2009). “Bimonthly Photovoltaic Industry

Update.” Solar Outlook. Issue SO2009-1. Palo Alto, CA: Navigant Consulting, Inc.

14

NREL. (2009). “Concentrating solar power plants of the southwest United States.” Golden, CO:

National Renewable Energy Laboratory (internal only).

Renewable Energy Policy Network for the 21

st

Century (REN21). (2009). Renewables Global

Status Report 2009 Update. Paris, France: REN21 Secretariat. www.ren21.net/publications.

Accessed July 2009.

Sherwood, L. (2009). U.S. Solar Market Trends 2008. Latham, NY: Interstate Renewable Energy

Council (IREC). http://irecusa.org/irec-programs/publications-reports/. Accessed August 2009.

Solar Millennium. (July 1, 2009). ”Andasol I is officially inaugurated.” Press Release.

http://www.solarmillennium.de/Press/Press_Releases/Andasol_1_is_officially_inaugurated,lang2

,50,1660.html. Accessed August 2009.

15

2. Industry Trends, Photovoltaic and Concentrating Solar Power

This chapter covers global and U.S. PV and CSP industry trends. Section 2.1 summarizes global

and U.S. PV cell/module production trends, including production levels, growth over the past

decade, and top producers. Section 2.2 presents data on global and U.S. PV cell/module

shipments and associated revenue, including shipment levels and growth over the past decade,

top companies in terms of shipments, shipment levels by type of PV technology, and U.S. import

and export data. Section 2.3 provides information on major CSP component manufacturers and

CSP component shipments. Section 2.4 discusses material and supply-chain issues for PV and

CSP, including polysilicon, rare metals, and glass supply for PV; material and water constraints

for CSP; and land and transmission constraints for utility-scale solar projects. Section 2.5 covers

global and U.S. solar industry employment trends for both PV and CSP.

2.1 PV Production Trends

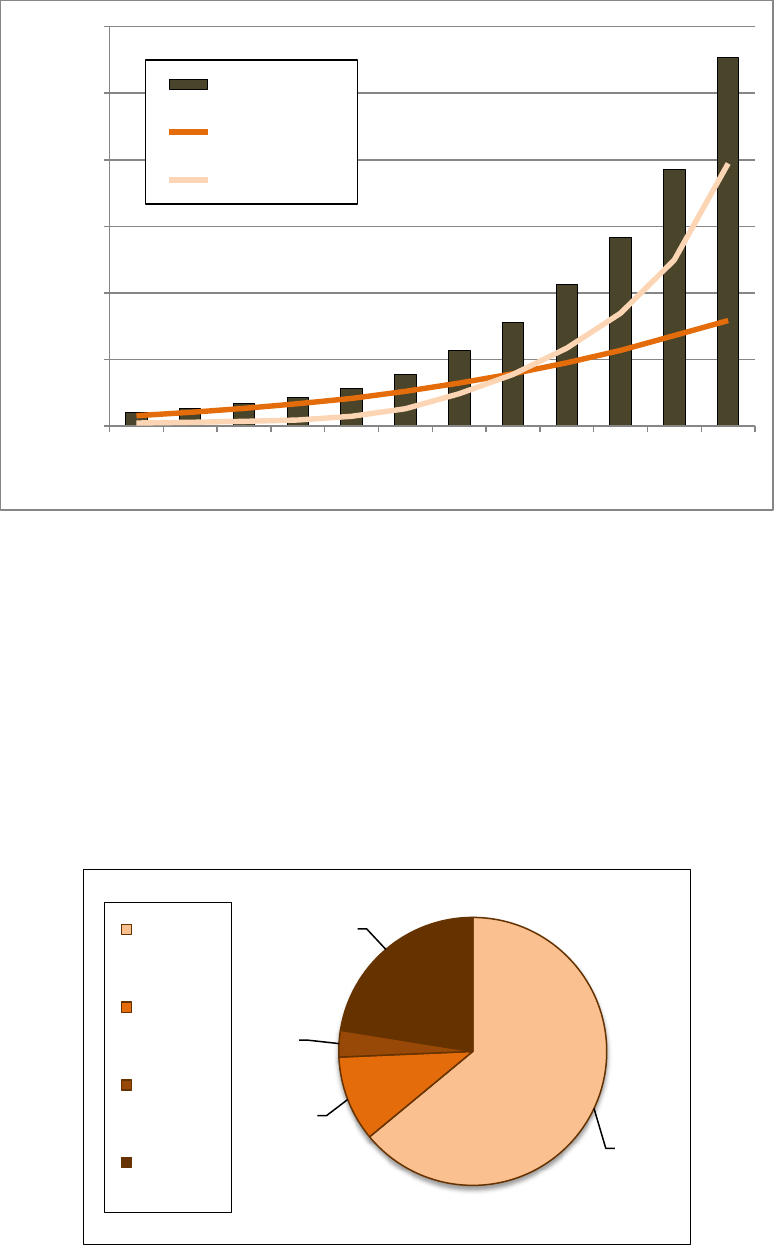

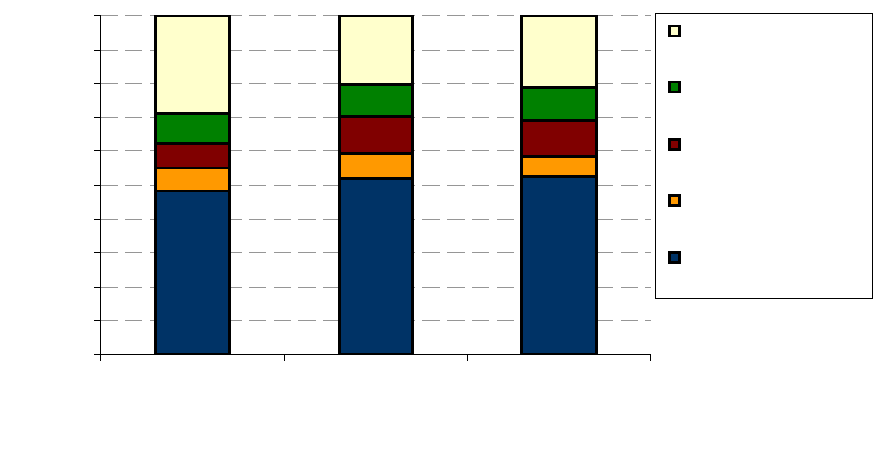

2.1.1 Global PV Production

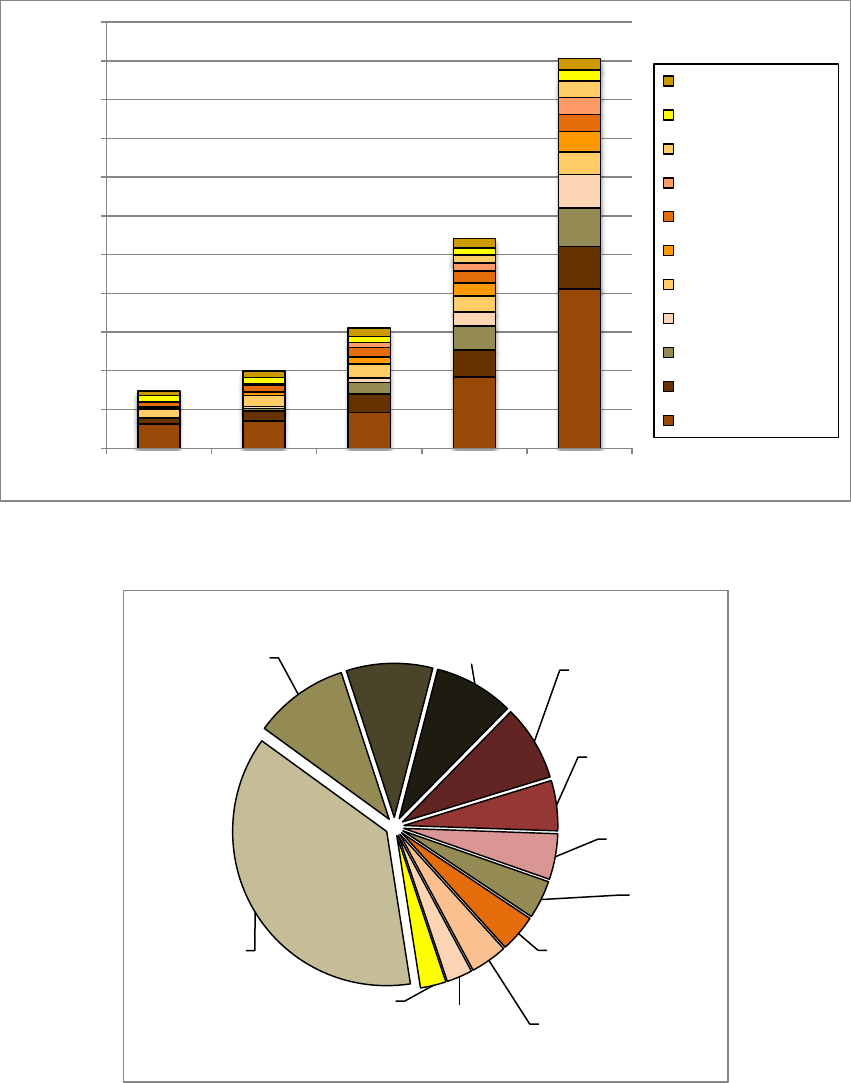

The global PV industry has seen impressive growth rates in cell/module production during the

past decade, with a 10-year CAGR of 46% and a 5-year CAGR of 56% through 2008. Annual

growth from 2007 to 2008 was 87%, higher than the 51% annual growth from 2006 to 2007.

Global production (Figure 2.1) reached 6.9 GW for the year 2008, an 87% increase over 3.7 GW

produced in 2007, which was led primarily by manufacturers in Europe, China, and Japan. The

market shares for the top regions/countries are 27% each for Europe and China, 18% for Japan,

12% for Taiwan, 6% for the United States, and 10% for the rest of the world (ROW). From 1997

to 2008, approximately 18.5 GW of PV cells were produced globally.

Figure 2.1. Global annual PV cell/module production by region

(Maycock 2002, Bradford et al. 2006, Bradford et al. 2008a, Bradford et al. 2009)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

1997

1998

1999

2000

2001

2002

2003

2004

2005

2006

2007

2008

Annual PV cell/module production (GW)

ROW

Taiwan

China

Europe

Japan

U.S.

16

Europe and Japan have had strong production growth rates during the past decade, with 10-year

CAGRs of 50% and 38% (from 1998–2008), respectively, resulting in their dominance of the PV

market. Europe and Japan increased their collective market share from 24% in 1980 to 76% in

2004. Since 2004, however, their combined share has dropped to approximately 45%, which is

due to the rapid growth of emerging producers such as China and Taiwan.

China has seen the highest growth rates in recent years, with a 5-year (2003–2008) CAGR of

170%. In 2001, China contributed only about 1% of global production; it did not become a

significant global contributor until 2005 when its market share reached 7%. Taiwan has also

experienced high growth rates, with a 5-year CAGR of approximately 119%, surpassing U.S.

production levels in 2007 to become the world’s fourth-largest producer. Taiwan continued to

gain market share over the United States in 2008. Production in Taiwan increased from

approximately 0.37 GW (10% market share) in 2007 to 0.85 GW (12% market share) in 2008.

The United States produced 0.27 GW (7% market share) in 2007 and 0.41 GW (6% market

share) in 2008.

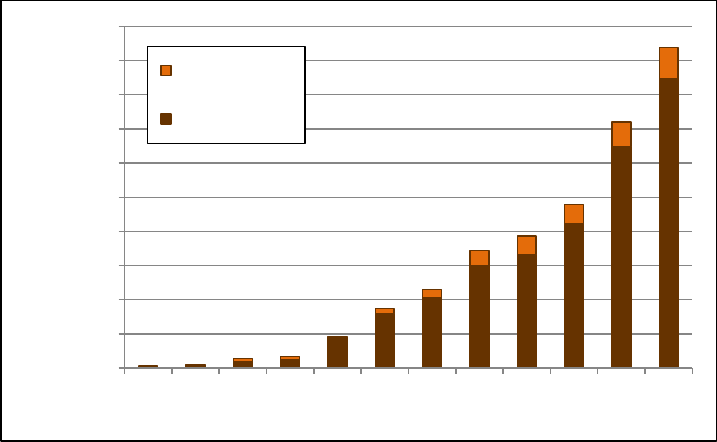

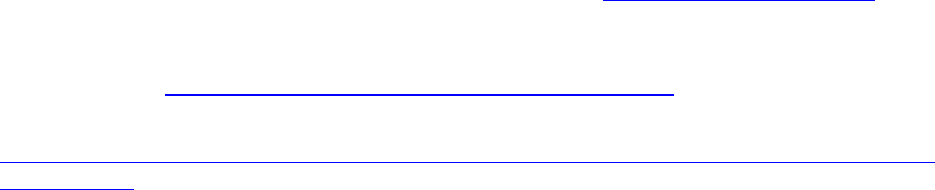

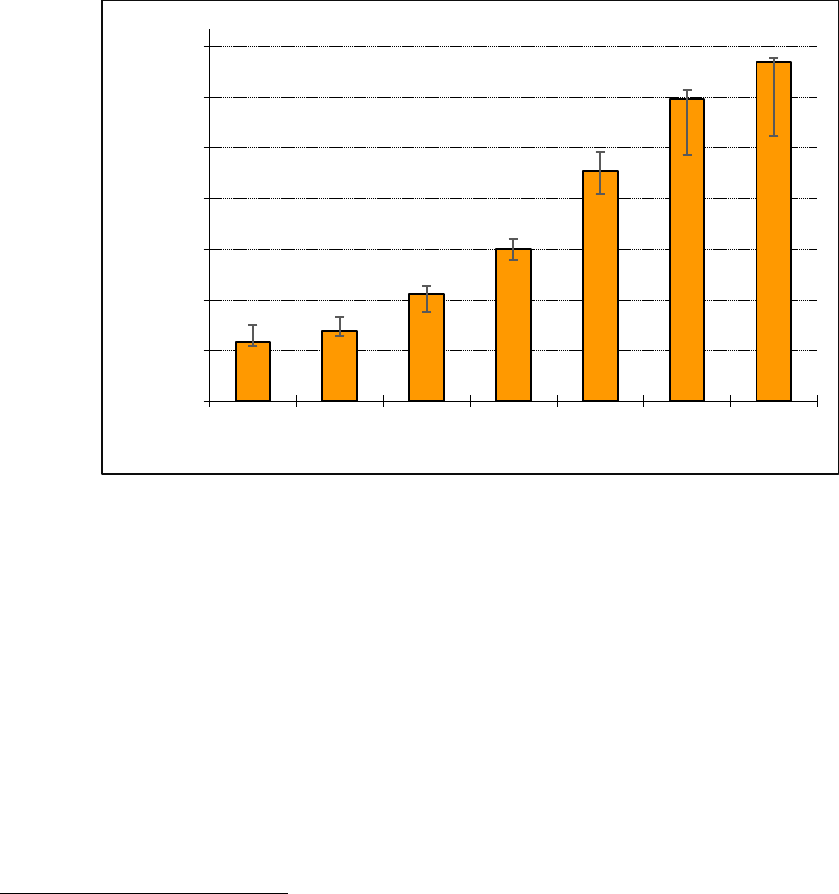

Figure 2.2 shows 2008 market shares for the top ten PV cell/module producers worldwide, and

Figure 2.3 shows production data for the top ten companies from 2002 to 2008. Japan-based

Sharp Corporation was the global leader in PV production between 2000 and 2006. In 2007,

German-based Q-cells overtook Sharp to become the world’s number-one producer at 0.39 GW

and maintained this position through 2008. Sharp’s market share for production continued to

decrease through 2008, dropping from 9% in 2007 to 6% in 2008. Q-cells also lost production

market share, dropping from 11% in 2007 to 8% in 2008.

Figure 2.2. Top global PV cell/module producers 2008

(Bradford et al 2009)

Q-Cells

0.57 GW

8%

First Solar

0.50 GW

7%

Suntech

0.50 GW

7%

Sharp

0.47 GW

6%

Motech

0.38 GW

5%

Kyocera

0.29 GW

4%

Baoding

Yingli

0.28 GW

4%

JA Solar

0.28 GW

4%

SunPower

0.24 GW

3%

Sanyo

0.21 GW

3%

Other

3.5 GW

49%

17

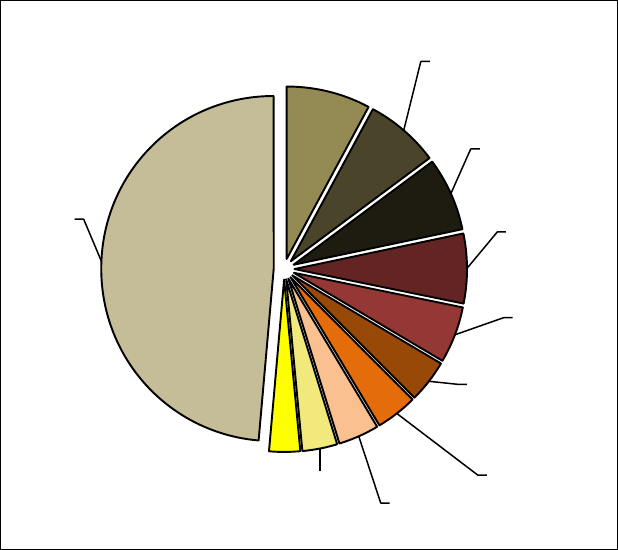

Figure 2.3. Global annual PV cell/module production by manufacturer 2002–2008

(Bradford et al. 2006, Bradford et al. 2008a, Bradford et al. 2009)

Q-cells, a crystalline and thin-film cell producer, has seen impressive growth rates since 2003

when it first became one of the top-ten producers. Q-cells had a 5-year (2003–2008) CAGR of

about 83%. The German company’s 2008 production was 47% greater than its 2007 production

of 0.39 GW. Although Q-cells has all of its manufacturing plants in Germany, its plans for future

expansion include development of overseas capacity in places such as Malaysia.

First Solar is a U.S. company with production facilities in the United States, Germany, and

Malaysia. First Solar became a top-ten producer for the first time in 2007 and maintained this

position through 2008. This marked the first time a predominantly thin-film manufacturer made

the top-ten list. First Solar, the largest U.S. PV cell/module manufacturer, was responsible for

36% of total U.S. production in 2008. First Solar is the world’s largest manufacturer of thin-film

(CdTe) modules with 0.15 GW of production in the United States, 0.20 GW of production in

Germany, and 0.16 GW of production in Malaysia in 2008. First Solar’s jump in the global

rankings is a result of high growth rates in recent years. Its 2008 production level grew to

0.50 GW in 2008, up 740% from the 2006 level. First Solar expects its capacity to exceed 1 GW

by the end of 2009. In addition to impressive production numbers, First Solar also boasted the

PV industry’s lowest cell manufacturing cost of $1.08/W in the third quarter of 2008 (First Solar

2008).

Suntech Power, a Chinese crystalline silicon company with production in China, was the third-

largest PV producer in 2008. The company has seen impressive growth rates in recent years,

producing 0.50 GW in 2008, up from 0.33 GW in 2007.

Sharp Corporation also has plans for growth. The Japanese company’s 2008 manufacturing

capacity was 0.86 GW, with most being crystalline cells. The company, however, plans to shift

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

2002 2003 2004 2005 2006 2007 2008

Annual PV cell/module production (GW)

Sanyo

SunPower

JA Solar

Baoding Yingli

Kyocera

Motech

Sharp

Suntech

First Solar

Q-Cells

Other

18

its focus from crystalline technologies to thin-film PV going forward. Sharp indicated it plans to

upgrade its current 15-MW, thin-film plant to a 160-MW plant. The company is also developing

a 1-GW, thin-film plant within a liquid crystal display (LCD) manufacturing facility. Sharp

estimates that the new factory will begin thin-film shipments in 2010.

Motech Solar, a crystalline silicon cell producer, is the largest PV producer in Taiwan and the

sixth largest globally. The company’s 2008 production of 0.38 GW is a 120% increase over its